CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

93

Note that this does not apply for HOPE pipes: their effective

thickness is the nominal wall thickness of the pipe. A low

temperature correction factor may apply to PVC pipes, refer to

the pipe manufacturer: if the temperatures are sub-zero, teffective

may be as low as 0.5t. Apart from protection from ultraviolet

degradation, this is another reason to bury PVC pipes at high

altitude.

2. Now calculate the safety factor (SF) from the following

equation:

SF=- 200 x teffective x S

htotal x d

where:

teffective is the effective thickness and d is the internal diameter

of the pipe. Note that same units (m or mm) should be used

for both teffective and d since they cancel out in the above equation.

S is the ultimate tensile strength of the pipe material in N/

mm2. Values of S and other useful parameters are shown in

Table 6.2.

htotalis the total head on the penstock as follows:

htotal = hgross + h surge

3. For mild steel or PVC pipes:

If SF < 3.5, reject this penstock option and repeat calculation

for thicker walled option. However, SF ≥ 2.5 can be accepted

for steel pipes if the surge head has been calculated accurately

and all of the following conditions are met:

a) There are experienced staff at site who have installed

penstock pipes of similar pressures and materials.

b) Slow closing valves are incorporated at the powerhouse

and the design is such that a sudden stoppage of the entire

flow is not possible.

c) Damage & safety risks are minimal. For example even if the

pipe bursts, it will not cause landslides or other instability

problems in the short run.

d)Careful pressure testing to total head has been performed

before commissioning.

Then from the manufacturer’s catalogue the actual thickness

should be chosen such that it is equal to or larger than the

calculated t .effective The Safety Factor should then be checked

using the actual thickness. For HDPE pipes, it is recommended

that the Safety Factor always be at least equal to 1.5.

6.6.2 NEGATIVE INTERNAL PRESSURE

Check the pipe wall thickness for buckling if the negative surge

can produce negative internal pressure in the pipe. Note that

the negative pressure must not exceed 10 metres head, see

Section 6.5.1. The shape of the negative surge pressure profile

cannot be accurately determined: assume it is horizontal in

the lower half of the penstock, and diminishes gradually in the

upper half to zero at the forebay, see Figure 6.3.

In order to provide an adequate factor of safety against

buckling, the minimum pipe wall thickness is given by:

teffective ≥ d(FP / 2E)0.33

where:

teffective is the effective pipe wall thickness, mm

d is the pipe internal diameter, mm

F is factor of safety against buckling (2 for buried penstock

and 4 for exposed penstock)

P is the negative pressure, N/mm2 (10 m head ≅ 0.1 N/mm2)

E is Young’s modulus for the pipe material, N/mm2 (from Table 6.2).

If the steel quality is uncertain it is best to ask for samples and

have them independently tested at laboratories. Properties of

PVC and HDPE vary considerably; they should be confirmed

from manufactures’ catalogues or by laboratory tests.

6.7 Pipe jointing

6.7.1 GENERAL

Individual mild steel penstock pipes can be joined at site by

two conventional methods, namely site welding and via

flanges. Each of these methods has its own advantages and

disadvan-tages as discussed in Table 6.3.

For HDPE pipes:

HDPE pipes are available in discrete thicknesses based on the

pressure ratings (kg/cm2) or static heads. The designer should

set SF ≥. 1.5 and calculate teffective (note that t = teffective for HDPE).

6.7.2 SITE WELDING

This involves transporting a welding machine and diesel or

petrol to site, then joining the pipes by welding together the

ends as shown in Photograph 6.10.

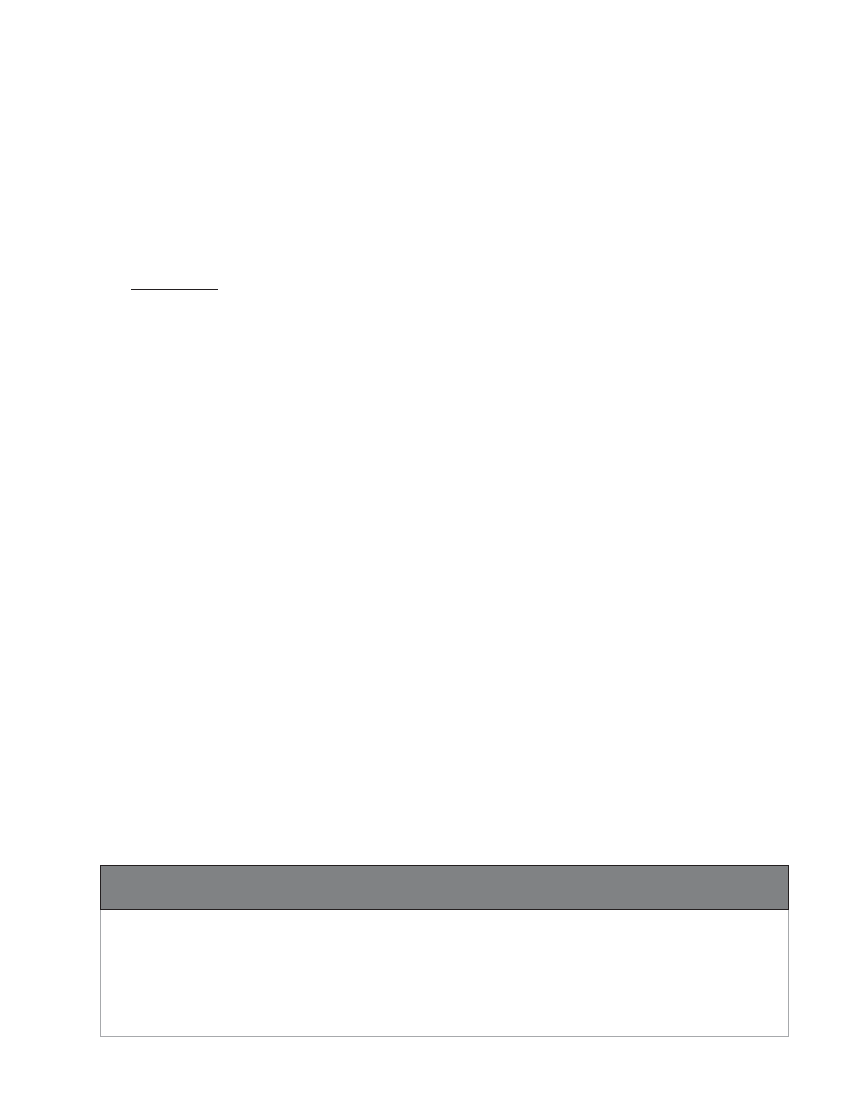

TABLE 6.2 Physical characteristics of common materials

MATERIAL

Steel (ungraded)

Steel to IS 226 / 75

or IS 2062/84

PVC

HDPE

YOUNG’S

MODULUS (E) N/MM2

2.0 x 105

2.0 x 105

2750

1000

COEFFICIENT OF LINEAR

EXPANSION (á ) °C

12.5x10-6

12.5x10-6

ULTIMATE TENSILE

STRENGTH (S) N/mm2

320

410

UNIT WEIGHT (Y)

KN/m3

77

77

(20 - 60) x 10-6

(140 - 240) x 10 -6

35-55

20-35

14

9.3