CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

43

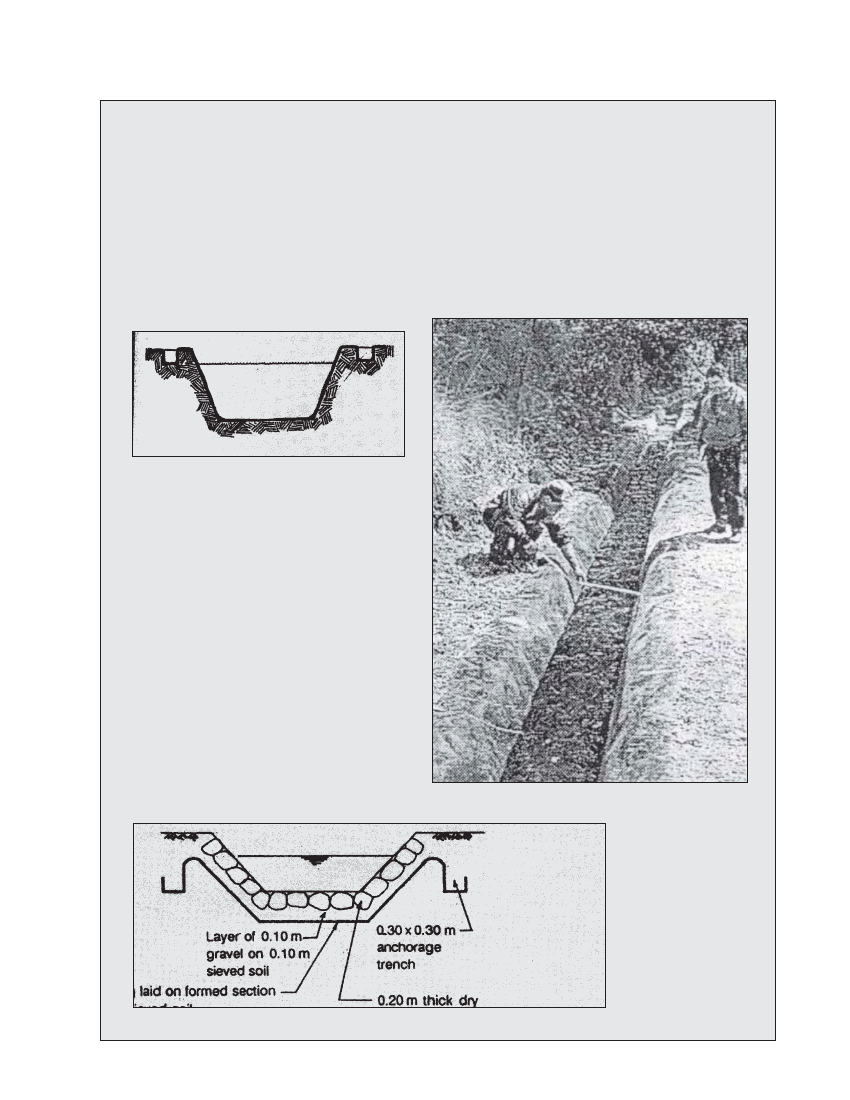

Box 4.3 Trials of HDPE linings at El Tinte, Peru

The installation of HDPE lining at El Tinte was carried out

in a trapezoidal excavation of 1.2 m width. The material

was laid in a single sheet of 25 m length in a straight

section of the canal as shown in Photograph 4.9. The

thickness of the HDPE sheet was 6 mm. The sheet was

anchored by excavating 150 mm square anchor

trenches parallel to the main canal on each side and

then ramming earth into the anchors, as illustrated in

Figure 4.2 below.

PVC and butyl/ rubber are some of the membrane types

commonly used. Note the differences in this design with

the El Tinte HDPE lining. For example, this design has

gentler side slopes and the lining is covered with sieved

soil, which protects it from being damaged by people

and cattle. This type of plastic lining minimises seepage

loss but requires more labour time for placing it. Laying

the plastic sheet needs careful attention to ensure that it

is not punctured.

Figure 4.2 HDPE Lining at El Tinte, peru.

The labour required for this operation was one

supervisor and one assistant for one day, although a

longer section or one involving curves, would have re-

quired greater time in jointing and cutting the material.

An analysis of costs shows the HDPE-lined canal to be

US$ 10 per m2 for materials delivered to site, which

results in $20 per linear metre of completed canal includ-

ing labour costs. The additional labour cost for a canal

with curves and joints is estimated to be US$ 0.30 per

linear metre.

An estimate of the cost of a concrete canal of the same

dimensions would be around US$ 12 per linear metre.

An alternative buried membrane lining method is pro-

posed in Ref. 5. This is shown below in Figure 4.3. HDPE,

Photo 4.9 HDPE lining at El Tinte, Peru

Figure 4.3 Buried membrane lining porposed in design manual’s for Irritation Projects in Nepal.