74 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

Ystorage = Vsediment / A

Where Ystoraeis the storage depth in the settling basin below

the hydraulic depth (y) discussed earlier, and A is the plan

area. The hydraulic depth and the storage depth are also

shown in Figure 5.3.

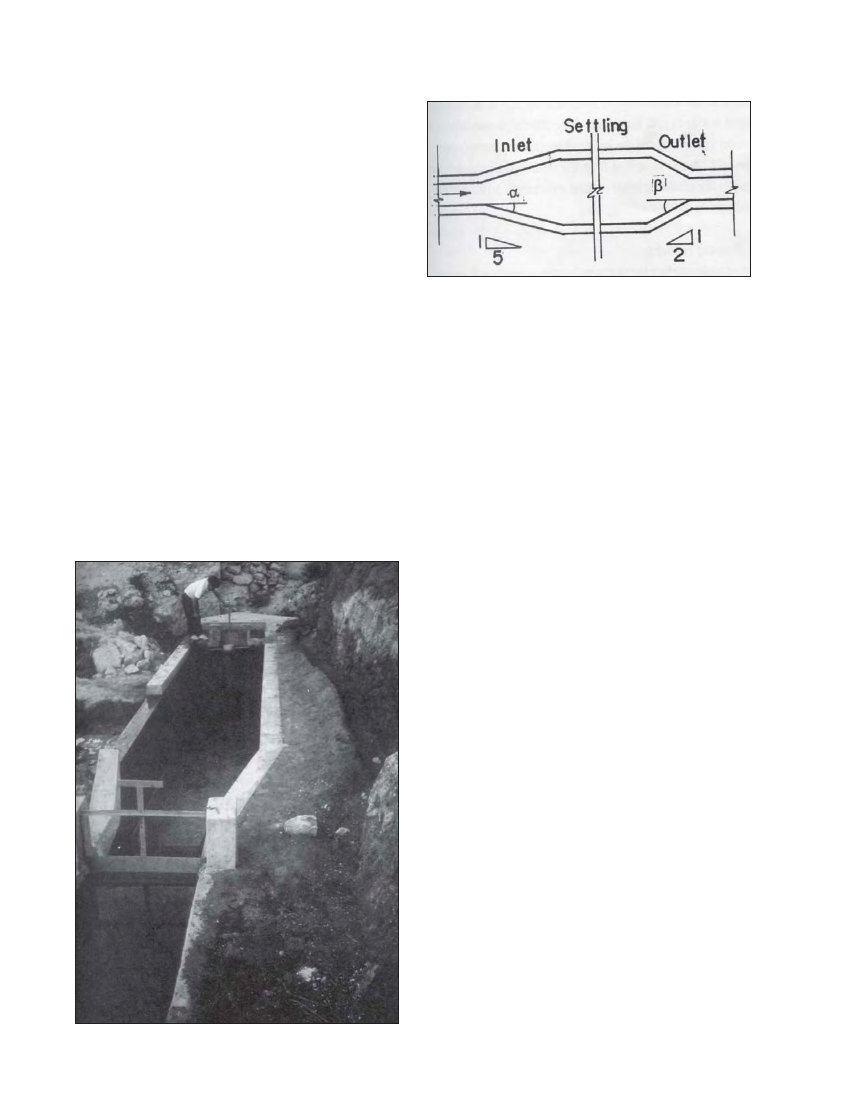

5.3.6 COMPONENTS OF A SETTLING BASIN

The settling basin has three distinct zones; the inlet, settling

and outlet zones. These are discussed below and shown in

Figures 5.3 and 5.4.

Inlet zone

This is the initial zone where the transition from the headrace

to the settling basin occurs and there is a gradual expansion

in the basin width.

The design of the inlet is important to the efficiency of the

basin. For high hydraulic efficiency and effective use of the

basin, the inlet should distribute the inflow and suspended

sediment over the full cross sectional area of the settling zone.

Various research data show that horizontal velocity variations

across the width of a rectangular tank affect the hydraulic

efficiency considerably more than velocity variations in depth.

Therefore, attention needs to be given to uniform flow

distribution in the horizontal plane. The following methods

are used in the inlet zone to achieve a good flow distribution:

Photo 5.2 Sliding gate at settling basin entrance, Peru

Figure 5.4 Expansion and contraction ration in settling basin

Gradual expansion of the inlet channel. This is the most

commonly used method in micro-hydro schemes.To

determine the length of the inlet zone, set the horizontal

expansion ratio at about 1:5 (a = 11°) as shown in Figure

5.4. This will allow an even flow distribution at the beginning

of the settling zone. The vertical expan-sion ratio can be

higher at about 1:2 (a = 27°) as shown in Figure 5.3.

Another option is to incorporate a weir as can be seen in

the Galkot settling basin (Drawing 420/04/3C01).

Troughs with slots or orifices in walls or bottom.

Baffle walls

Note that orifices or baffle walls are often used in water

treatment facilities where extremely low velocity is required

but these methods are rarely used in micro-hydro schemes.

In some schemes in Peru, a sliding gate is installed in front of

the settling basin as shown in Photograph 5.2. During

flushing, the gate is initially closed, impounding water behind

it. When the settling basin is emptied, the gate is opened and

the sudden rush of the impounded water flushes out any

sediment that has remained inside the basin.

Settling zone

The basin reaches the required width at the beginning of this

zone. Particles are settled, stored and flushed in this zone.

The length of this zone is longer than the inlet or the outlet

zones. It should be noted that long narrow basins perform

better than short wide basins. A range of 4 to 10 is

recommended for the ratio of the length to width (L/B). Basin

shape can also be improved by subdivision with a longitudinal

divide wall, since this doubles the L/B ratio for a given basin

length. Also, the longitudinal divide wall can assist in the

operation of the scheme. For example, the sediment in one

sub-basin can be flushed while the other is in operation,

producing half the power output. Without the subdivision,

the plant would have to be closed during flushing.

Provision for flushing the stored sediment should be at the

end of the settling basin. A floor slope of 1:20 to 1:51 in the

settling zone facilitates flushing.

Outlet zone

This forms the transition from the settling zone to the

headrace. The transition can be more abrupt than the inlet