64 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

Example 4.3 Siklis headworks

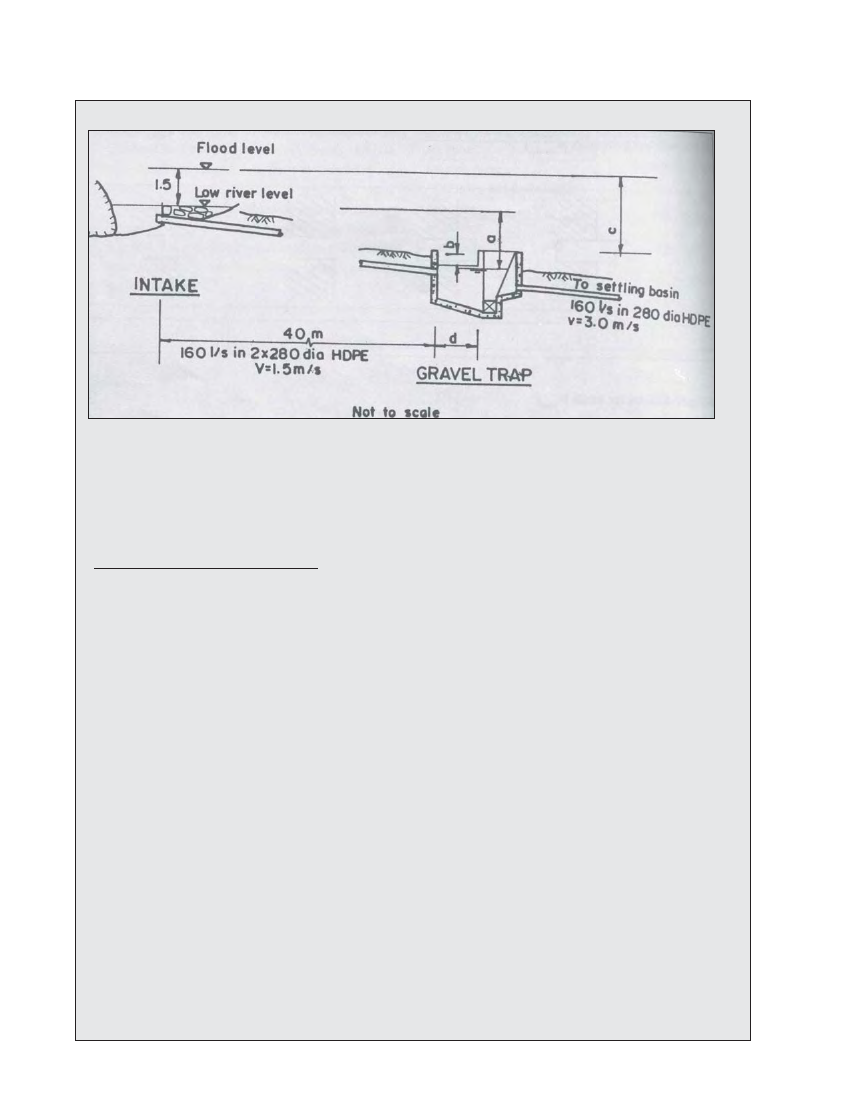

Figure 4.11 Headworks of the 100kw Siklis micro-hydro scheme (Siklis, Nepal)

A sketch of the headworks of the existing 100 kW Siklis micro-hydropower scheme is shown above in Figure 4.11.

Calculate the following:

1. Headloss in intake pipes

2. Design water level in gravel trap

3. Flood flow through intake pipes

4. Spillway length at gravel trap

1. Headloss in intake pipes at design flow

a) Pipe friction

For 280 mm diameter. Class II HDPE pipe manufactured in Nepal, internal diameter = 262 mm

Flow per pipe (Q) = 160/2 = 80 1/s

From Table 4.3, assume k = 0.06 mm

or, k / d = 0.06mm / 262mm = 0.00023

or, 1.2Q / d = 1.2x0.08 / 0.262 =0.366

f = 0.0166 (from Moody Chart, Figure 4.10)

... hwall loss = fLQ2 / i2d5

= 0.0166x40x.0.082 / 12x0.2625 = 0.29m

b) Inlet headloss

Kentrance = 0.8 for this case (Table 4.4}

hinlet loss = Kentrance x V2 / 2g

Check velocity;

V = 4Q / IId2 = 4x0.08 / IIx0.2622 = 1.5 m/s

hinlet loss = 0.8x1.52 / 2x9.8 = 0.09m

c) Exit headless

hexit toss = Kexit x V2/2g

1.0x1.52 / 2x9.8 = 0.11m Total headloss in intake pipes = 0.29 m + 0.09 m + 0.11 m = 0.49 m