CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

123

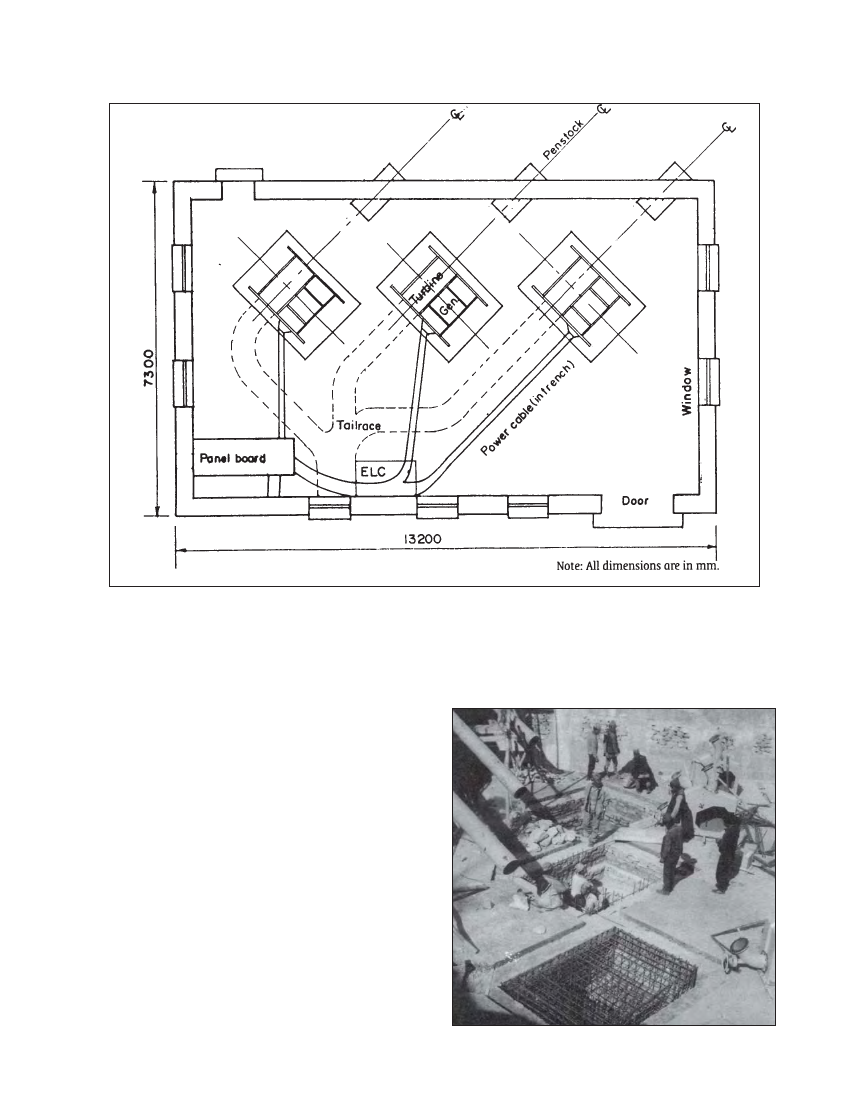

Figure 8.1 Powerhouse floor plan at the Jhankre mini-hydro scheme

The minimum wall thickness of the stone masonry walls

(mud mortar) should be 450mm. If funds are available at

least the external surface of the walls should be plastered

in cement-lime mortar (12mm thick, 1:1:6 mix) to keep

away moisture from rain.

The penstock pipe should not normally be built into the

powerhouse wall, otherwise the wall could be damaged by

vibration from the turbine. The recommended solution is

to leave an oversized opening in the wall; an alternative is

to place a bigger pipe outside the penstock pipe where it

passes through the wall. At Jhankre mini-hydro the wall

was locally thickened to act as a support pier for the penstock

pipes entering the powerhouse.

The clear height of the building should be 2.5m to 3m.

For larger schemes, provision must be made for lifting

equipment that cannot be lifted by hand. A crane is

expensive; more appropriate is a block and tackle supported

by a beam or temporary A-frame.

CGI sheets should be used for the roofing, since they are

relatively fire resistant and leak proof.

The floor of the powerhouse should be 300mm to 500mm

above the outside ground surface to prevent dampness and

rainwater entering. Drains should also be provided outside

the powerhouse.

Doors and windows should open outwards for safety in

case of fire or flooding.

8.4 Design of machine foundation

The design of the machine foundation is similar to that of an

anchor block, but simpler. The most significant forces that the

machine foundation can experience are as follows:

Photo 8.4 Construction of Jhankre mini-hydro machine foundation.