CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

165

Steel Industries P. Ltd.

G.P.O Box 4129. Kanlipath, Jamal.Kaihmandu. Napal. Tel: 977-1-253047, 228389. 243452, 252475. 252850,

Fax: 977-1-220612 Factory : Simra. Bara. Tel: 977-53-20075, 20078, 20170. Fax: 977-53-20160

STRUCTURAL

STEEL PIPES

Structural steel pipes are manufactured in the same process as water pipes. However, the steel used is of

higher tensile/yield strength. We normally use high grade steel with tensile strength of 42/55 kgs/cm as per

customers requirements. We normally use the steel as per JIS: G-3132, SPHT2,3or4, or IS: 11513/1985 for

the pur-poses. Structural pipes are basically used for manufactur-ing poles and welded structures. Use of

high grade struc-tural steel reduces steel consumption drastically Pipes of structural grade normally conform

to IS: 1161/1979, JIS: G-3444/1993, BS: 1387/1985.

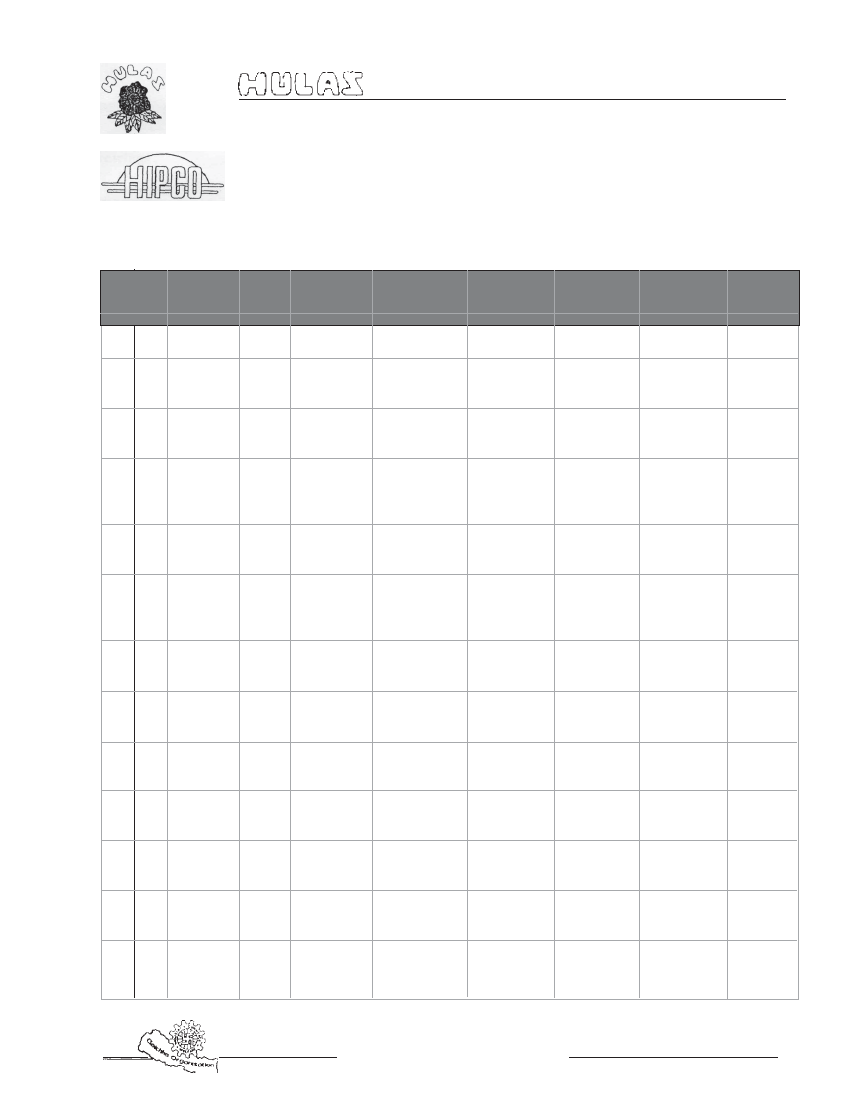

HIPCO STRUCTURAL TUBES

NOMINAL

BORE

mm inch

15 1/2

20 3/4

25 1

32 11/4

40 11/2

50 2

65 21/2

80 3

100 4

125 5

150 6

175 7

200 8

OUTSIDE

DIAMETER

mm

21.30

26.90

33.70

42.40

48.30

60.30

76.10

8890

114.30

139.70

165.10

193.70

219.10

CLASS

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

LI

L2

M

H

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

THICKNESS

mm

2.00

2.65

3.25

2.35

2.65

3.25

2.65

3.25

4.05

2.65

3.25

4.05

2.90

3.25

4.05

2.90

3.25

3.65

4.50

3.25

3.65

4.50

3.25

4.05

4.85

3.65

4.50

5.40

4.50

4.85

5.40

4.50

4.85

5.40

4.85

5.40

5.90

4.85

5.60

5.90

WEIGHT

(BLACK PIPES)

kg/m

0.96

.22

.45

.42

.58

.90

2.04

2.46

2.99

2.61

3.15

3.86

3.27

3.61

4.43

4.14

4.57

5.10

6.17

5,84

653

7.92

6.86

8.48

10.01

9.97

12.10

14.50

14.90

16.20

17.90

17.80

19.20

21.20

22.60

25.00

27.30

25.70

29.40

31.00

AREA OF

CR. SECTION

Cm

1.21

1 55

1.84

1.81

2.02

2.41

2.58

3.11

3 77

331

4.00

4.88

4.14

460

5.63

523

5.82

6.50

7.89

7.44

8.31

10.10

8.74

10.80

1280

12.70

15.50

18.50

19.10

20.50

22.80

22.70

24.40

27.10

28.70

31.90

34.80

32.60

37.60

39.50

MOMENT OF

INERTIA

Cm

0.57

0.69

0.77

1 38

1.50

1.72

3.14

365

4.22

6.57

7.71

9.07

10.70

11.73

13.90

21.59

23.77

26 17

30.90

49.44

5465

65.12

80.31

97.38

11346

194.39

234.32

274.54

437.20

467.64

514.49

732.57

784.49

864.69

1284.00

1416.96

1536.11

1874.06

2141.59

2247.00

SECTION

MODULUS

Cm

0.54

0.65

073

1.02

1.12

1.28

1.86

2.16

2.51

3.10

3.64

4.28

4.43

4.86

5,75

7.16

7.89

8.68

1020

13.00

14.40

17 10

18.07

21.91

25.53

34.01

41.00

48.04

62.59

66.95

73.66

88.74

95.03

104.75

133.00

146.30

159.00

171.07

195.49

205.11

RADIUS OF

GYRATION

Cm

0.69

0.67

0.65

0.87

086

084

.10

.08

.06

41

39

.36

.61

.60

.57

2.03

2.02

201

1.98

2.58

2.56

254

3.03

3.00

2.98

3.91

3.89

386

4.78

4.77

4.75

5.68

5.67

5.65

6.68

6.66

6.64

7.58

7.55

7.54

Tolerance:

a) Thickness: (+) not limited (-) 10% b) Weight: (+) 10% (-) 8%

c) Outside Daimeter: Upto 48.3 mm, (+) 0.4 mm (-) 0.8 mm, (+) 1%

A JOINT VENTURE BETWEEN