CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

47

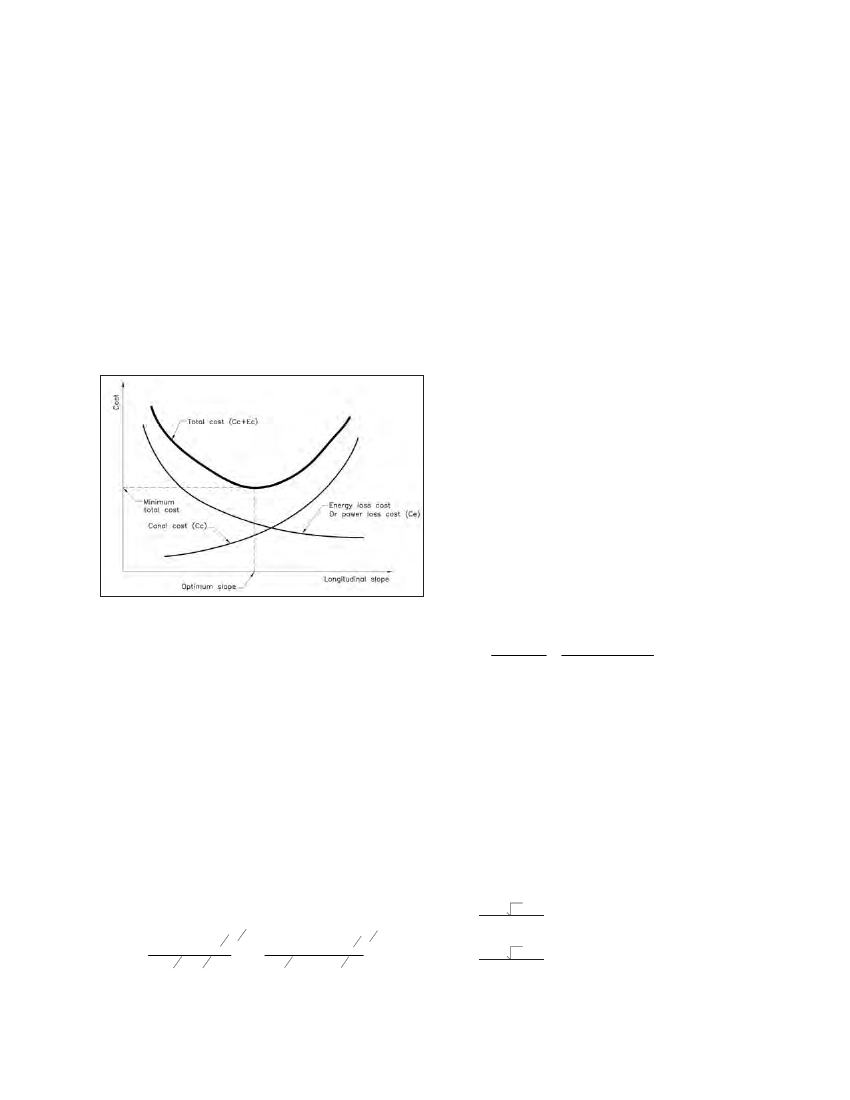

in the example. Then head loss in 1m length of canal for each

case should be calculated. The corresponding energy loss (or

power loss in most cases of micro-hydro) due to the head loss

over a year should be calculated. Then, the cost corresponding

to the energy loss should be calculated and the sum of energy

or power loss cost discounted over the plant’s economic life

(generally 15 years) for a discount rate (generally 10 %) is

determined. Note that the discount rate is the opportunity

cost of investment in the prevailing market and should be

greater than or at least equal to the prevailing lending rates

for infrastructure projects by the commercial banks of the

country. The longitudinal canal slope corresponding to the

minimum of sum of canal cost and energy loss cost as shown

in Figure 4.6 will be the optimum canal slope which

determines the canal size (depth and width).

Figure 4.6 Canal optimization

Canal optimization example

Design flow which was fixed earlier based on hydrology and

electricity demand , Q= 300 l/s =0.3 m3/s

Decide canal shape and lining method (according to site

condition): Rectangular, stone masonry (1:4) with base slab

and side walls, t=300 mm=0.3 m thick and free board,

F= 300 mm=0.3 m

Manning’s constant from table 4.1, n= 0.02

Assume an appropriate longitudinal slope of canal, S=1/500

(1 in 500) in this case

Select a width to depth ratio, B/D=r=2, (generally 2 is

optimum if site condition allows and should be lowered if

width is a constraint)

D

=

⎡

⎢

⎣⎢

Q

×n×

5

r3

(r +

1

×S

2)

2

2

3

3

⎤8

⎥

⎥⎦

=

⎡

⎢

0.3

×

0.02

×

(2

+

2)

2

3

⎣⎢

51

2 3 × (1/ 500) 2

3

⎤8

⎥

⎦⎥

=0.43m

Note that the above equation is derived from Manning’s

equation. Sizing and quantity calculations can be done

similar to this procedure for unlined or trapezoidal canal using

Manning’s equation.

Considering length of canal, L=1 m

Base slab:

B=r*D=2*0.43=0.86 m

Width, W=B+2*t=0.86+2*0.3=1.46 m

Quantity, Vb=W*t*L=1.46*0.3*1=0.44 m3

Walls:

Wall height, H=D+F=0.43+0.3=0.73 m

Quantity, Vw=2*t*H*L=2*0.3*0.73*1=0.44 m3

Total quantity, Vt=Vb+Vw=0.44+0.44=0.88 m3

Stone masonry rate, say Rm=4000 Rs/m3

Cost of canal, Cc=Vt*Rm=0.88*4000=Rs 3200

Head loss, HL=L*S=1*1/500=0.002 m

Overall efficiency, e=0.5, generally for micro-hydro

Power loss based on the power equation discussed in Chapter

1, PL=QgHLe=0.5*9.81*0.3*0.002=0.00294 kW=2.94 W

Power tariff, Rp =Rs 1.0 per kW/month (say)=NRs 12 per kW/

year

Energy/Power loss cost per annum, C=PL*Rp=2.94*12=Rs

35.28

If the tariff is based on energy i.e., Per kilo Watt Per hour

basis, then energy loss (EL, kWh) all around the year should

be calculated considering the plant factor (P) (generally 0.2 to

0.5 for micro hydro). Then energy loss should be multiplied

by energy rate (Re, Rs/kWh) to determine cost of loss over a

year (C).Thus, EL=8760*P*PLC=EL*Re

Assuming the following parameters for the financial analysis:

Plant’s economic life N=15 years

Discount rate, i=10%

Discount factor of annuity

DFA

=

(1 + i)N − i

i × (1 + i)N

=

(1 + 10%)15 −10%

10% × (1 + 10%)15

=9.76

Therefore power loss cost, Ce=C*DFA=35.28*9.76= Rs.

344.33

Now, total cost, Ct=Cc+Ce=3200+344.33=Rs. 3544.33

Similarly costs for various canal slopes should be calculated

and plotted to find the minimum total cost (as shown in

Figure 4.6). The corresponding canal longitudinal slope for

the minimum total cost will be the optimum slope.

4.3.2 MANNING’S EQUATION

The design of a headrace canal is based on Manning's equation.

Manning's equations for flow and velocity are as follows:

Q

=

AR2/3

n

S

V=

R2/3 S

n

where:

Q is the flow in the canal in m3/s

V is velocity in the canal in m/s