80 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

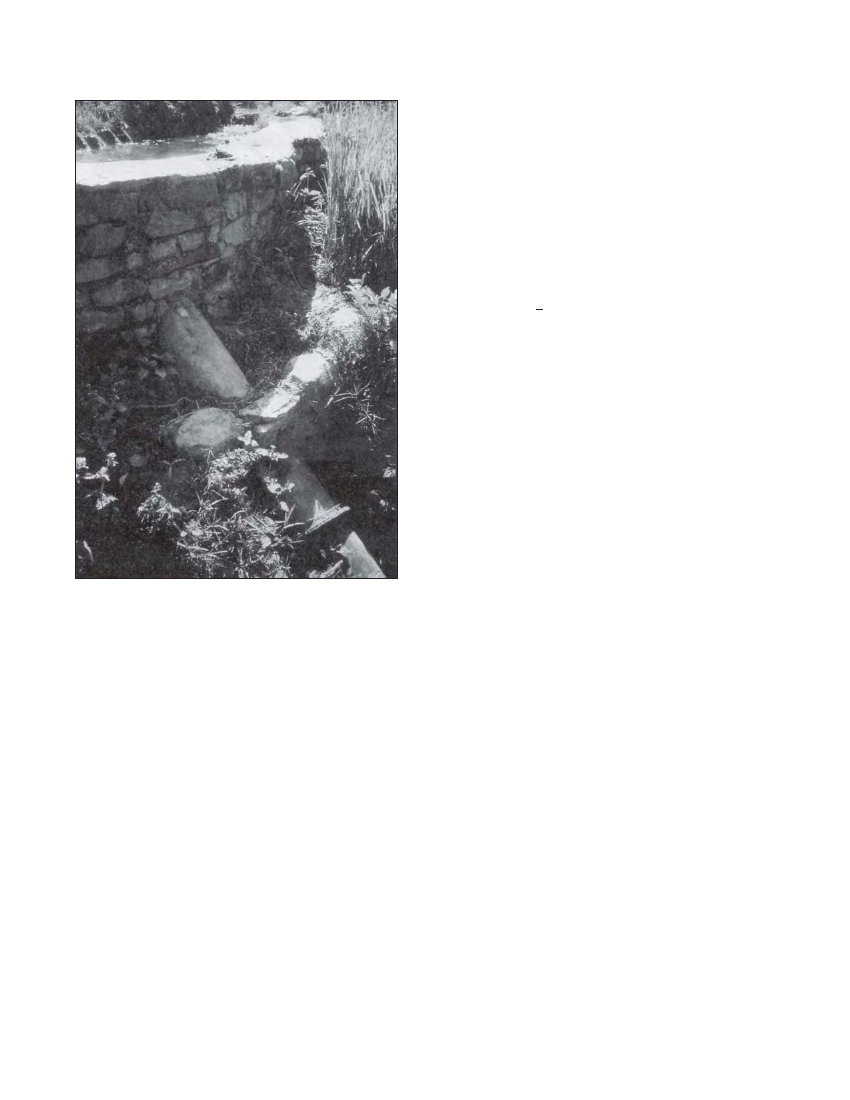

Photo 5.9 A dry stone masonry forebay showing the connection

with the penstock

Chialsa mini-hydro scheme is based on such conventional

flushing system as can be seen in Photograph 5.6.

5.4 Forebay

5.4.1 GENERAL

The forebay of a micro-hydro scheme serves the following

functions:

It allows for the transition from open channel to pressure

flow conditions.

It regulates the flow into the penstock, particularly through

the release of excess water into a spillway.

It releases the surge pressure as the wave travels out of the

penstock pipe.

It can also serve as a secondary/final settling basin and

trap some particles that enter the headrace downstream of

the settling basin.

Although very rare in micro-hydro schemes, the forebay

can also provide water storage for use during peak power

demand period as discussed in Box 5.2.

Structurally, the forebay tank is similar to the settling basin

except that the outlet transition is replaced by a trashrack and

the entrance into the penstock pipe.

5.4.2 PIPE LEVEL

The forebay allows for the transition from open channel to

pipe flow by providing adequate submergence for the penstock

pipe. As discussed in Chapter 4, if the submergence head is

not sufficient, the pipe will draw in air and be unable to

convey the design flow. Similarly, recall from Chapter 4 that

the minimum submergence head required for the penstock

pipe is as follows: hs>1.5V2 / 2g where: hs is the submergence

head, and V is the velocity in the penstock.

5.4.3 DESIGN OF A FOREBAY

If the length of the headrace canal between the settling basin

and the forebay is long, then sediment can enter the canal,

such as when debris falls from uphill of the headrace alignment.

Similarly if an earth canal (or stone masonry in mud mortar)

is constructed between the settling basin and the forebay,

sometimes high velocity in the canal, such as during the

monsoon, can cause erosion and carry sediment to the forebay.

In such cases the forebay should also be designed to serve as

a secondary settling basin and the design method used for

sizing a settling basin should be used. However, a lower

sediment concentration (say C = 0.5 kg/m3) can be used since

only particles that have escaped the settling basin or those

that have been eroded from the headrace canal are expected

in the forebay. If the headrace upstream of the forebay consists

of HDPE pipe or of cement masonry canal and the settling

basin is functioning well, there will not be any need for

secondary settling. However, as a precaution, some storage

depth below the pipe invert should be allowed for. A depth of

300 mm or equal to the pipe diameter, whichever is larger is

recommended for this purpose.

5.4.4 FOREBAY SIZE

The minimum size of the forebay should be such that a person

can get in and clean it. The minimum clear width required

for this is 1 m. Even if the sediment load is not expected in

the forebay, it may sometimes reach this structure such as

when the settling basin is filled in quickly during the monsoon

or there is a small landslide. If a person can get into the

forebay and clean it occasionally or during the annual

maintenance period, limited sediment accumulation will not

be a problem. A storage depth below the invert of the penstock

should be provided for this, as can be seen in Figure 5.8.

If possible, the forebay should also be sized such that 15

seconds of the design flow can be safely stored in the tank

above the minimum pipe submergence level. This is more

important if the scheme consists of a headrace pipe instead

of a canal. There can be small transient surges in the headrace

pipe which result in uneven flow. The 15 second storage

capacity helps to balance such uneven flows.

5.4.5 TRASHRACK