12 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

2.5.2 PROCEDURE TO ESTABLISH THE DESIGN FLOW

1. Conduct a flow measurement at site during the dry season

(November-May). Preferably in February for snow-fed rivers

and March/April for other rivers. Not if the year is drier

than average, or wetter than average. This can be

established by talking to the locals. Consider if there are

significant abstractions by other water users, such as

irrigation and drinking water schemes upstream of the point

where the gauging was conducted.

2. Calculate:

Average monthly flows by using WECS/MIP methods.

Flow duration curve using WECS.

Instantaneous flood flows of different return periods using

WECS.

3. Compare the dry season mean monthly flows obtained by

WECS and MIP method. If the flow measured at site is

above average according to the local people, compare the

dry season mean monthly flow obtained by the WECS

method with that obtained by the MIP method, and use

the lower value. If the flow was measured at site during

either a wetter than average year or a drier than average

year, then use the value obtained by the WECS method.

4. Use the flow duration curve (FDC) to establish the probability

of exceedance of the value from step 3. The FDC is useful

because the power equivalent of the flow can be superimposed

onto it, so that it is possible to read off the amount of time

each year that certain power levels can be obtained. This is a

useful planning tool, allowing a choice of size of turbine to

be made, together with an indication of required variable

flow performance of turbine and an indication of the plant

factor constraints which will result from any particular choice

of turbine size. See Ref.1 for details.

5. Decide on what percentage of the flow established in step 3

can be diverted for power generation. If using a temporary

weir assume that 50 percentage of the flow can be diverted.

If the river presents formidable difficulties, assume less than

50 per centage. If using a permanent weir founded on bedrock

assume 95 per centage and for weir based on alluvium

foundation, allow for seepage losses and assume that 90

percentage of the flow can be diverted.

6. Calculate seepage losses for the water conveyance structures.

These losses must be deducted from the flow established

in step 5. Seepage calculation is covered in Section 2.5.3.

7. Consider if there are other water users such as irrigation

and drinking water downstream of the diversion works.

Establish the amount of flow that has to be released

downstream and deduct this amount from the flow from

step 6. This is the design flow.

A design example is included in Appendix A.

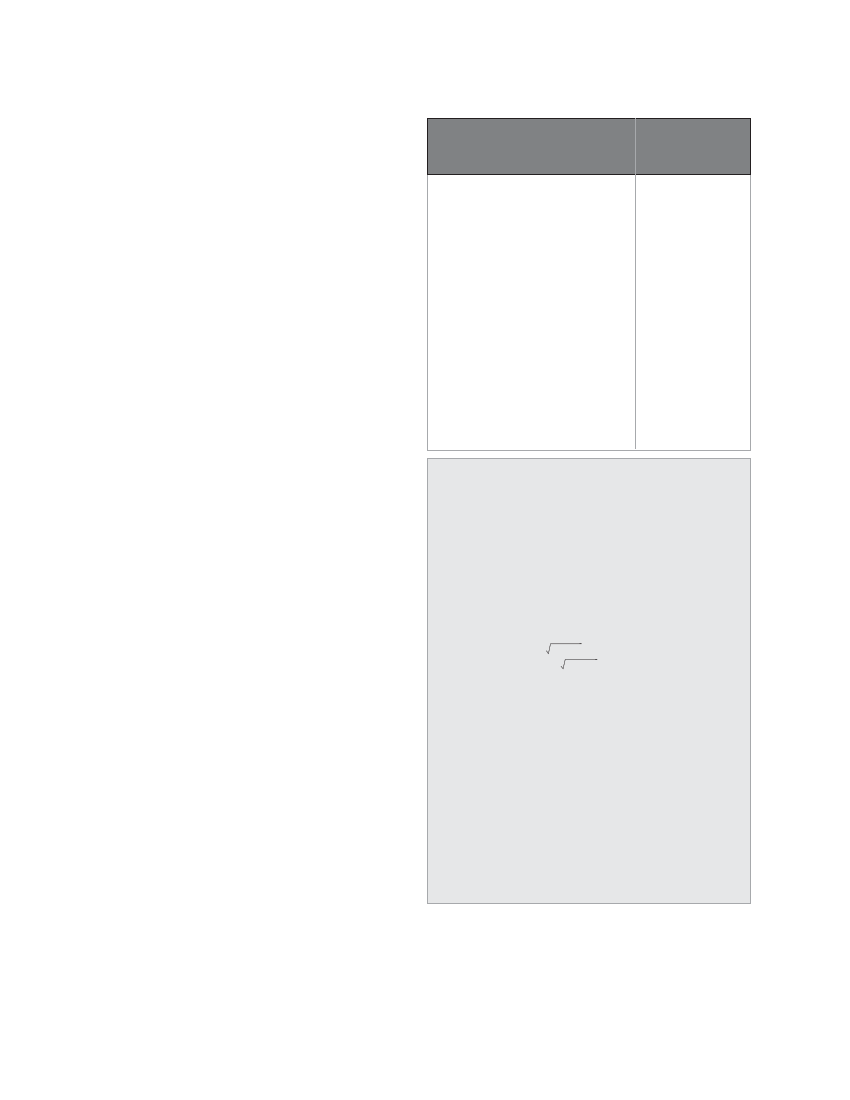

TABLE 2.3 Canal seepage losses

TYPE OF SOIL

Rock

Impervious clay loam

Medium clay loam

Clay loam or silty soil

Gravelly clay loam or sandy

clay or gravel cemented with clay

Sandy loam

Sandy soil

Sandy soil with gravel

Pervious gravelly soil

Gravel with some earth

SEEPAGE LOSS,

(l/S/1000 m2 OF

WETTED AREA)

<0.5

0.8 -1.2

1.2-1.7

1.7-2.7

2.7 - 3.5

3.5 - 5.2

5.2 - 6.4

6.4 - 8.6

8.6 -10.4

10.4 - 20.8

Example 2.1 Seepage Calculation

A 500 metre long unlined headrace canal is to be constructed

in sandy clay to convey a design flow of 0.1m3/s. A standard

trapezoidal section is proposed with a depth of 0.2 m, a bot-

tom width of 0.6 m and side slopes of 1:2 (V:H). Calculate the

seepage loss in the canal.

Solution:

The wetted perimeter (P) of the canal can be calculated using

the following equation:

P = B + 2 x H x (l+N2) (see chapter 4)

= 0.6 + 2 x 0.2 x (l + 22) = 1.49m

The wetted area

=PxL

= 1.49 x 500

= 747 m2

From Table 2.1, seepage loss in sandy clay is 3.5 l/s/1000 m2

of wetted area. The seepage loss is given by:

Qseep = 3.5 x wetted area/1000

= 3.5 x 747 /1000

= 2.6 l/s

Which is 2.6% of the designed flow of the canal.

2.5.3 SEEPAGE

It is imperative to examine the soil along the route of the

proposed canal and estimate the amount of seepage that a

canal may suffer, an important issue that is often overlooked

by micro-hydro designers. This is especially true for micro-

hydropower schemes with long unlined canals. Table 2.3 gives

canal seepage losses for different soil types. By calculating