CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

81

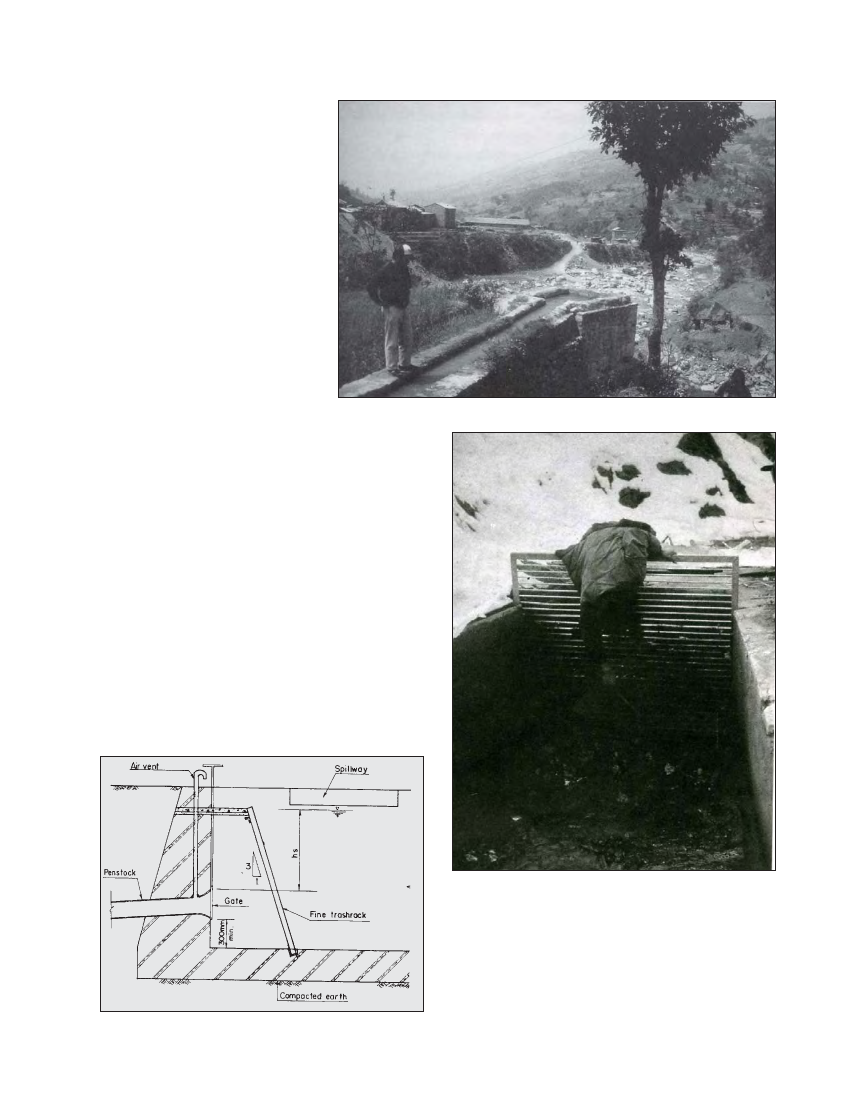

The trashrack at the forebay should be

placed at 1:3 slope for both efficient

hydraulic performance and ease of

cleaning (such as by raking) as shown in

Figure 5.8. To minimise headless and

blockage, the recommended velocity

through the trashrack is 0.6 m/s. but a

maximum of 1 m/s could be used.

It should also be noted that the trashrack

bars should be placed vertically since

horizontal bars are difficult to clean as

shown in Photograph 5.11. The spacing

between the trashrack bars should be

about half the nozzle diameter for Pelton

turbines and half the runner width for

crossflow turbines. This prevents the

turbines from being obstructed by debris

and minimises the chances of surge.

Photo 5.10 A cement masonry channel and forebay at the top of a steep slope (Dhading)

Cleaning of the trashrack can be minimised by fixing it such that

it is submerged during the design flow as in the case of the

Salleri Chialsa mini-hydro (Photograph 5.12.). Here the top level

of the trashrack is below the design water level. Any floating

debris such as leaves are washed by the flow above the trashrack

and spilled via the spillway. Although this type of arrangement

facilitates self-cleaning of the trashrack, some additional flow

(than the design flow) will be constantly required.

5.4.6 SPILLWAY

As discussed earlier, a spillway should also be incorporated at

the forebay. The spillway should be sized such that it can

release the entire design flow when required. This is because

if the turbine valve is closed during emergencies, the entire

design flow will have to be spilled from the forebay until the

operator reaches the intake or other control structures upstream

of the forebay.

Figure 5.8 Forebay

Figure 5.8 Forebay

Photo 5.11 Cleaning can be difficult with horizontal bars.

Photo 5.11 Cleaning can be difficult with horizontal bars

5.4.7 GATE AND VENT

Incorporating a gate at the entrance of the penstock will make

the maintenance work of the turbine easy. The gate can be

closed, thus emptying the penstock and work can be done in

the turbine. However, a rapid closure of this gate will create a

negative pressure (i.e. vacuum) inside the pipe and could

cause it to collapse. Placing an air intake pipe as shown in

Figure 5.8 will prevent such a situation since air can be drawn