CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

75

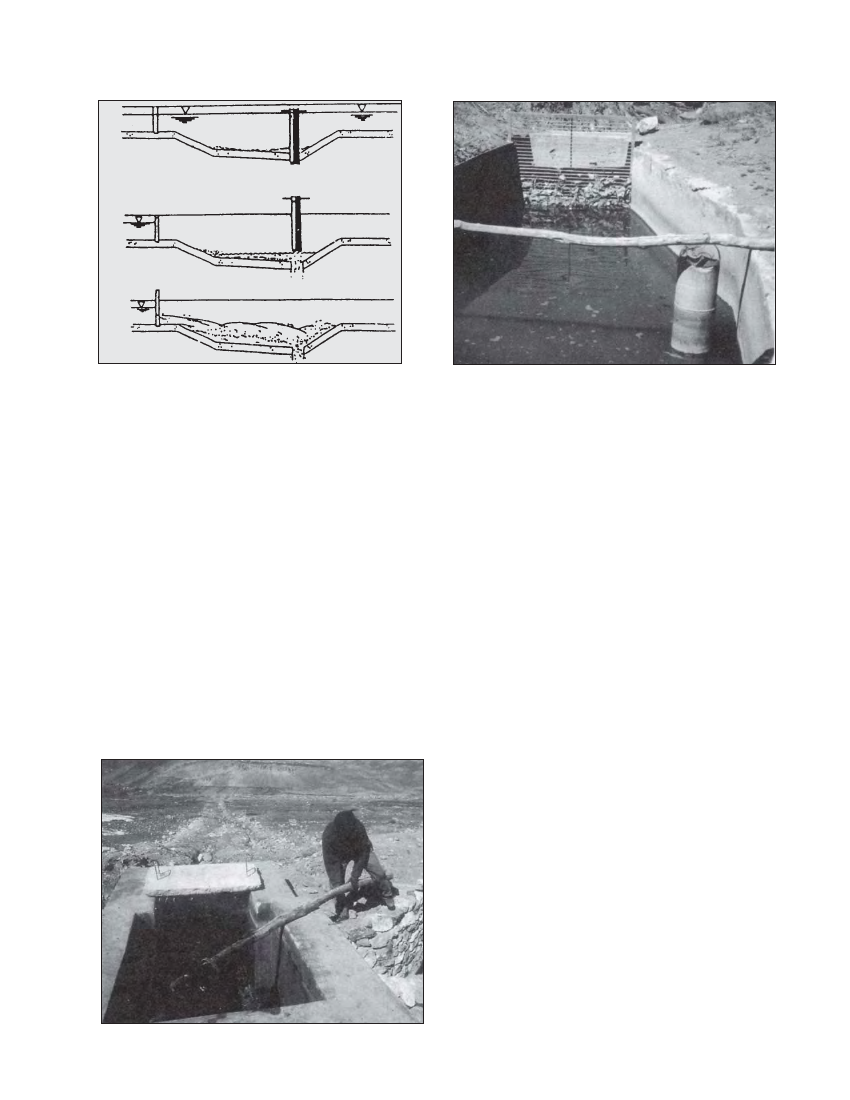

Figure 5.5 Flushing settling basin using the vertical

flush pipe method

expansion (i.e., horizontally 1:2 or p = 26.5° as shown in

Figure 5.4, and vertically 1:1 as shown in Figure 5.3). Note

that if the settling basin is combined with the forebay, then

this zone is not necessary: the forebay structure can be directly

downstream of the settling zone.

The operating water level of the settling basin is generally

controlled at the outlet, sometimes by a weir which may be

designed to operate as submerged in order to conserve head.

5.3.7 FLUSHING ARRANGEMENTS

Vertical Hush pipe method

There are various ways of removing the stored sediment from

the settling basin. An appropriate method for micro-hydro

settling basins is the “vertical flush pipe”. This uses a detach-

able vertical mild steel pipe over a hole in the basin floor. A

drain pipe is fixed below the basin floor to convey the flow

out of the basin. When the vertical flush pipe is lifted, the

water stored in the basin and the incoming flow along with

the sediment are drained through the hole. Apart from being

simple, the other advantage of this system is that it can spill

Photo 5.3 Lifting the flushing mechanism (Jhong)

Photo 5.4 Jharkot settling basin

some excess flow such as during floods when the water level

in the basin is above the normal level. This vertical flush

method is shown schematically in Figure 5.5. The Galkot

settling basin is based on this method as can be seen in

Drawing 420/04/3C01 of Appendix C. Similarly, the jharkot

micro-hydro scheme also uses this method for flushing as can

be seen in Photograph 5.3. The diameter of the flush pipe is

governed by the following criteria:

a) Overflow capacity

It needs to spill the excess flood flow that enters the basin as

shown in Figure 5.6. This is governed by the weir equation,

where the perimeter of the pipe is used for the length as follows:

Qflood =ΠdCwhflood3/2

where:

Qflood is the expected flood flow in the basin

hflood is the depth of water above the vertical pipe during Qflood

This is the height between the top of the vertical flush pipe

and the top of the settling basin wall.

Cw is the weir coefficient for a sharp edged weir, which is 1.9

(see Table 3.3, Chapter 3). The reason for using the sharp

edged weir coefficient is because the pipe thickness is small

compared to the head.

In terms of the pipe diameter, the above equation can be

rewritten as follows:

d = Qflood / 1.9Πhflood 3/2

To ensure draining of excess flow and to prevent spilling of the

design flow the height of the vertical flush pipe should be such

that the top level is 50mm above the design water level. Also

note that if the settling basin is combined with the forebay,

it may be more important to size the flush pipe diameter such that

it is able to spill the design flow. This is because if the turbine

valve is closed during emergencies, the entire design flow will

have to be spilled from the forebay until the operator reaches the

intake or other control structures upstream of the forebay.