CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

101

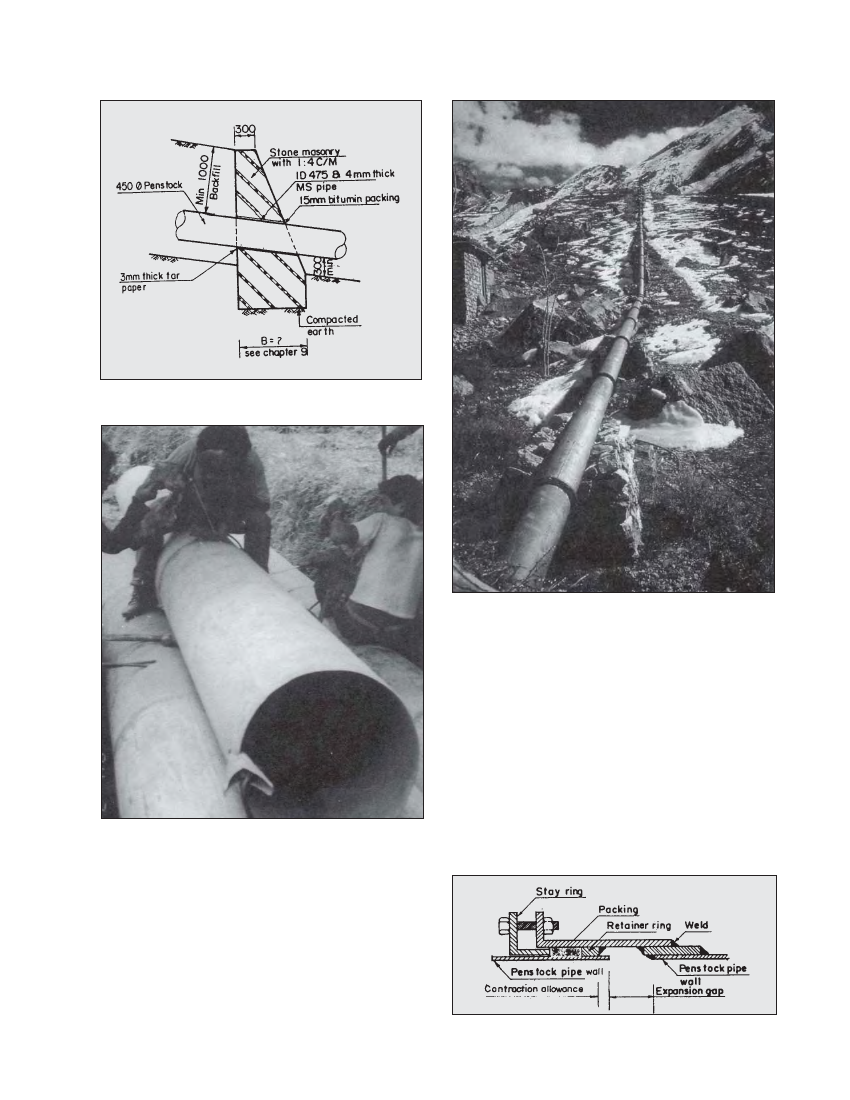

Figure 6.5 Transition from buried to exposed penstock, Jhankre

mini-hydro

Photo 6.11 Penstock, Purung

Photo 6.10 Site welding of penstock pipes, Jhankre mini-hydro

PVC pipes

PVC pipes with glued joints require provision for expansion,

at the same locations as for steel pipes.

Sizing of expansion joints

The sliding surface of the expansion joints should be machine

finished (such as in a lathe machine) to a tolerance of about

0.1 mm. The recommended thickness of the steel parts

(retainer and stay ring) is about twice the thickness of a well-

designed penstock pipe.

The gap in the expansion joint should be about twice the

calculated maximum pipe expansion length.

The maximum expansion length is calculated using the

following equation:

where:

= α (Thot - Tcold) L

L = pipe expansion length in m as shown in Figure 6.7. α =

coefficient of linear expansion in m/m °C of the pipe, which

depends on the pipe material. This coefficient relates to the

length that a material will expand per 1°C increase of

Figure 6.6 Sliding type of expansion joint