46 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

4.3 Canal design

4.3.1 DESIGN CRITERIA

The following criteria are used for the design of headrace

canals:

Capacity

The headrace canal should be able to carry the design flow

with adequate freeboard. Freeboard is the difference in

elevation between the canal bank top and the design water

level. During monsoon, the river water level is high and

therefore flows higher than the design flow can enter the

intake. Spillways and escapes are required to discharge the

excess flows. Similarly if falling debris or other obstructions

block the canal, the entire flow needs to be safely discharged

into a nearby gully or stream before it induces further instabil-

ity problems.

Velocity

The velocity should be low enough to ensure that the bed and

the walls of the canal are not eroded. The recommended

maximum velocity for different types of canal is shown in

Table 4.1. If the velocity is too low, aquatic plants and moss

will start to grow on the canal and reduce the cross sectional

area. A minimum velocity of 0.4 m/s should be maintained to

prevent the growth of aquatic plants. Also, the velocity in the

headrace canal up to the settling basin needs to be high enough

to prevent sediment deposition.

Headless and seepage

As mentioned earlier headloss and seepage need to be mini-

mised. Headloss is governed by the canal slope. Seepage can

be controlled by choosing the construction materials (earth,

mud or cement mortar canals etc.) appropriate for the ground

conditions.

Side slopes

Theoretically, the optimum cross sectional shape for a canal is

a semi-circle, since it can convey the maximum flow for a

given cross sectional area. Since it is difficult to construct a

semi-circular canal, in practice, a trapezoidal shape (which is

close to a semi-circle) is used. For masonry canals in cement

mortar or plain concrete canals that are continuous, rectangular

shapes (i.e., vertical walls) are recommended unless the

backfill can be well compacted or excavating the required

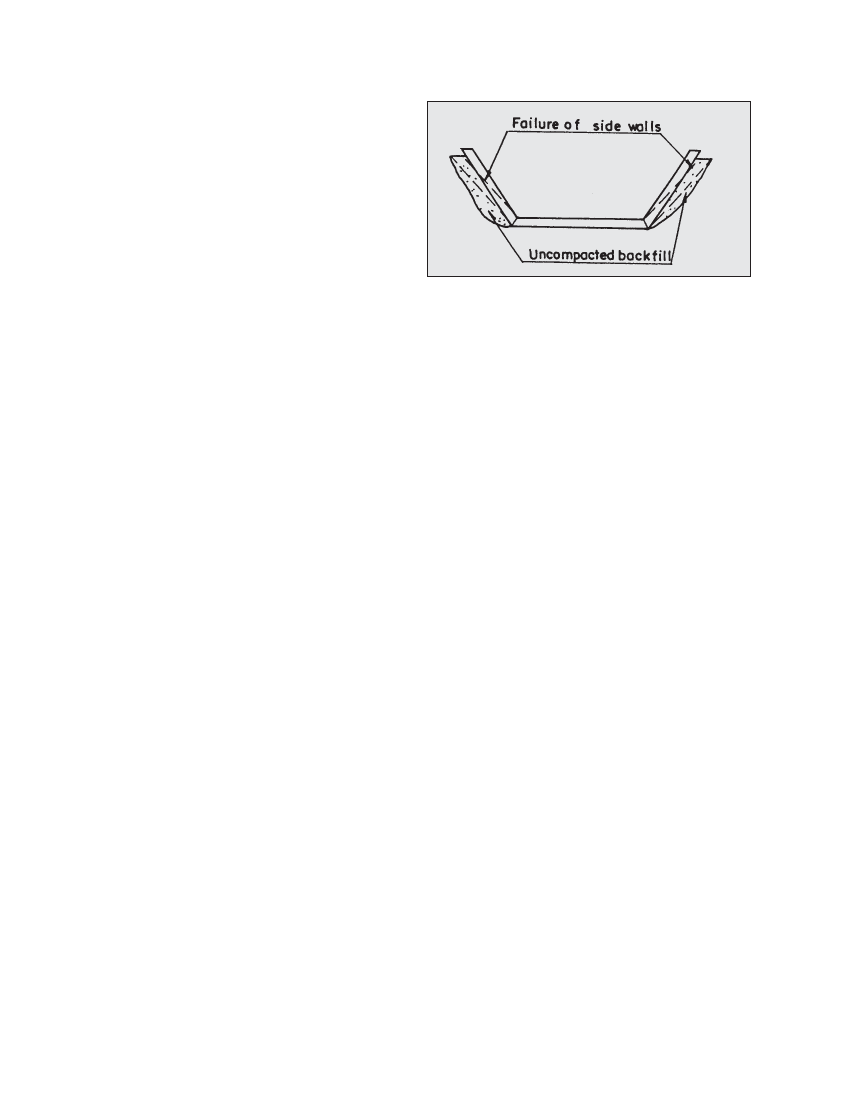

trapezoidal shape is possible. This is because trapezoidal

cement masonry and plain concrete canals’ side walls will

have to depend on the backfill for support. The walls may

crack at the canal bed level (causing seepage) since it may be

difficult to compact the backfill properly behind the walls, as

shown in Figure 4.5. Recommended side slopes for different

canal types are shown in Table 4.2.

Stability

Not only should the canal be on stable ground but the areas

above and below the alignment also need to be stable. When

Figure 4.5 Failure of side walls for rigid trapezoidal canals

determining the canal route at site, the signs of stability and

instability discussed in Chapter 2 should be referred to.

The canal design should address stability issues such as

protection against rockfalls, landslides and storm runoff.

Covering canals by placing concrete slabs (or flat stones) and

some soil cover (to absorb the impact of falling rocks) can be

an appropriate solution if a small length of the canal is

vulnerable to rockfalls. Examples of concrete slabs can be seen

in the superpassage drawings of the Galkot scheme in

Appendix C.

Economics

Similar to any other engineering structure, the design of the

canal should be such that the cost is minimised. This is

especially important in the case of a long headrace canal since

optimising the design will result in substantial saving in the

total project cost. Design optimisation or minimising costs

requires keeping the canal alignment as short as possible

(unless longer lengths are needed to avoid unstable areas

and crossings) as well as minimising excavation and the use

of construction materials, especially cement and stones. For

example, in a micro-hydro scheme, cement masonry canal

could be used only at sections where the soil is porous and/or

seepage is likely to trigger landslides. In the same scheme,

earth and stone masonry in mud mortar canals could be used

at sections where problems associated with seepage are not

expected. Where the headrace canal constitutes a significant

portion of the total project cost, it would be worthwhile to

optimise the canal dimensions.

Optimisation of canal may also be worthwhile if the design

flow is large, the length is long or expensive canal lining is

required. For optimisation of the canal, the least cost method

is generally used. A schematic diagram of the canal

optimisation process is presented in Figure 4.6. Then cost of

1m long canal for a given design flow and different

longitudinal slopes should be calculated. Note that the canal

dimensions (depth and width) are primarily dependent on

the longitudinal slope and hence accounted once the design

flow and the lining type is finalised. Generally the costs

involved are: excavation and lining costs. For simple cost

comparison only lining cost in case of lined canal and

excavation cost in case of unlined canal should is considered