104 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

pump. If any leakage is noticed, the section should be

repaired such as by tightening the bolts, changing faulty

gaskets or welding. For buried pipe alignment, the backfill

should only be completed after successful pressure testing;

however, if there are any minor bends without anchor blocks,

these must be backfilled before pressure testing. Once the

pipe trench is backfilled, it will be difficult and time

consuming to reexcavate and identify the leaking section.

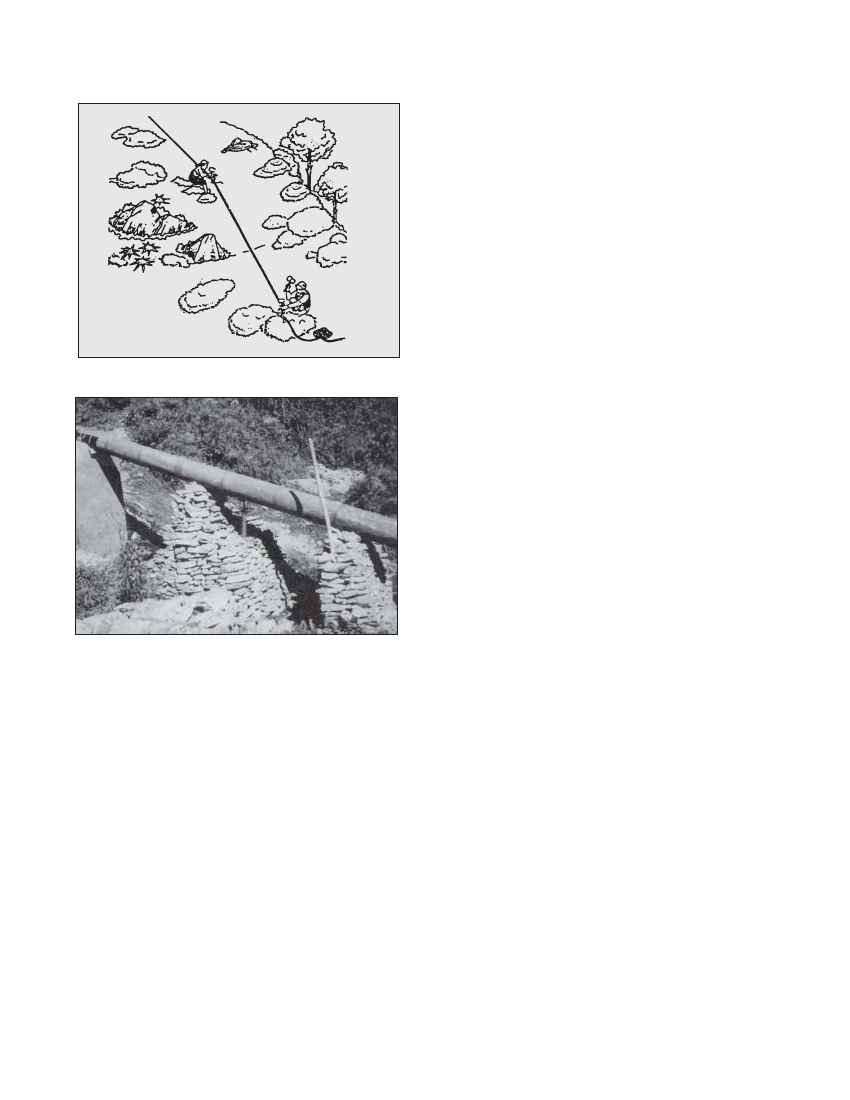

Figure 6.8 Setting out the centreline of the penstock alignment

6.13 Maintenance

Above ground mild steel penstocks should be repainted every

3 to 4 years depending on the conditions. Nuts, bolts and

gaskets of flange connected mild steel pipes should be checked

annually, loose bolts should be tightened and damaged gaskets

should be replaced. A visual check for flange leaks should be

carried out monthly. For buried penstock sections, signs of

leakage such as the sudden appearance of springs along the

alignment (especially during winter) and moist ground where

the area was previously dry should be checked. If any leakage

is noticed, the penstock should be drained and carefully

excavated for repair of the leaking section

Photo 6.15 Temporary support for site welding work, jhankre

mini-hydro, Nepal

not feasible at the machine foundation. For micro-hydro

schemes, laying of penstock in discrete lengths is not

recommended since this can lead to misalignments of

the pipes.

Penstock pipes should be pressure tested at the factory

before transport to site. For schemes where the head is

more than 15 m the completed penstock should also be

pressure tested during the commissioning phase. If feasible

such pressure test should include the surge head (i.e.,

pressure test at htotal). This can be done by simulating the

expected surge head at the forebay using a manual pressure

6.14 Checklist for penstock work

Refer to Table 6.1 and decide on the penstock material.

When in doubt compare the costs of all available options.

Is the alignment on practical ground slope? Is there

adequate space for the powerhouse area at the end of the

penstock alignment? Have the bends been minimised?

For mild steel pipes refer to Table 6.3 to decide on flange

connection or site welding. Also be sure to specify

appropriate coats of paint.

If a buried penstock alignment is being considered, refer to

Table 6.4 to compare the advantages and disadvantages,

and Figure 4.8 for the trench details.

Is the pipe diameter such that the headloss is between 5%

and 10%?

Has allowance been made for surge effects while sizing the

penstock wall thickness?

Is the safety factor sufficient as discussed in Section 6.6?

Are the pipe lengths and weights such that they are

transportable and porterable?

Refer to Section 6.12 for pipe installation at site.