138 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

Hence, design improvements are required before this debeader

and can be used in the field.

Commercial debeaders are also available but they are

expensive. Some such commercial debeaders can also remove

beads after the joints have cooled (i.e. cold debeading).

Photograph 10.5 shows a section of an HDPE pipe which was

cold de-beaded using a commercial debeader. Further

information on commercial debeaders can be obtained

from:

Fusion Group PLC

Chesterfield Trading Estate,

Chesterfield S419PZ,

England,

UK Fax: +44(0)1246450472

Such discs are suitable for venting of both liquids and gases.

The disc is manufactured to burst within its tolerance only

when installed in a suitably designed and manufactured

holder. Some of the main advantages of graphite bursting

discs are that they are not adversely affected by misaligned

pipe work or overtorquing of pipe flange bolts. Due to the

sufficiently high burst pressure, this type of disc does not

require backpressure support to withstand full vacuum

pressure. The discs have an operating ratio of 90% and are

guaranteed to rupture within a maximum of 30 milliseconds.

The discs are also inexpensive and in case of rupture due to

surge pressure, all that is required to recommission the pipe

10.4 Bursting disc

As discussed in Chapter 6, penstock pipes for micro-hydro

schemes are designed to accommodate the surge head when

setting the pipe thickness. An increase in the pipe thickness

also increases the cost of the pipe. Furthermore, depending

on the location of the site, the transportation cost also

in-creases. In a high head scheme with a long penstock

alignment, the increase in cost to accommodate the surge

head can be significant.

There are many ways to guard against surge damage but

most involve significant cost (where, for safety reasons the

flow has to be constrained) or involve great care in installation

and maintenance.

The “bursting disc” technology may provide a reliable means

of safely releasing the excess head in case of surge pressure.

A “bursting disc” is a commercially available over-pressure

safety device made from a brittle material such as graphite or

an appropriate metal, or a suitable metal which is designed to

rupture extremely quickly once a critical pressure is exceeded,

such as the surge head induced inside the penstock pipe in

the event of a jet blockage. Such discs are commercially used

in the chemical industry to protect pipelines and pressure

vessels (that convey gas and petroleum fluids) from high surge

pressure. Pipes that have bursting discs do not need to be

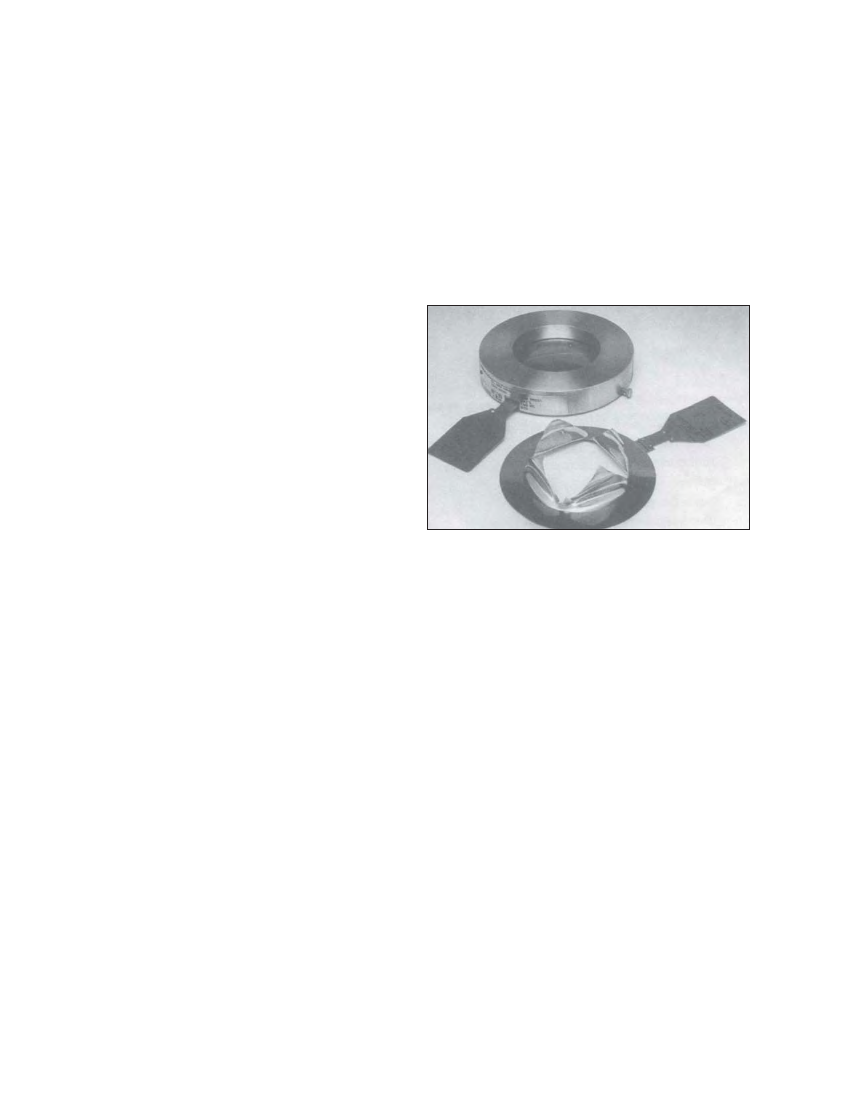

designed to accommodate surge pressures. Photograph 10.6

shows a commercially available bursting disc (including the

burst plate). Note that scratch lines are made in the plate

during manufacture to introduce weaknesses in the plate

such that it bursts according to the pattern shown in

Photo-graph 10.6 once the prescribed pressure is reached.

Most graphite discs are flat, deform very slightly under a

pressure differential and because of their physical properties,

at the set pressure shear instantaneously around the periphery

of the disc active area giving immediately full bore venting.

Photo 10.6 A commercially available bursting disc

is to replace the graphite plate. Hence, this technology could

be highly suitable for micro-hydro schemes including those

located in remote areas. Theoretical research on the

applicability of bursting discs for micro-hydro schemes has

been undertaken by Dulas in conjunction with Warwick

University. The bursting disc arrangement proposed by the

study is shown below in Figure 10.2.

Note that in case of the rupture of the disc, the flow would

discharge inside the turbine casing. Such an arrangement is

well suited in micro-hydro schemes since a separate flow

control structure is not required.

The conclusions of the above study were as follows:

The disc could reduce surge pressure by 60% to 70% if the

subsequent flow rate through the branching arrangement

is only moderately reduced. The reason why the entire

surge head cannot be eliminated is because the diameter

disc is usually smaller than the penstock diameter and hence

the flow is reduced.

The penstock safety factor could be reduced from 3.5 to 2.5.

These theoretical findings need to be thoroughly verified by

actually installing the discs in existing micro-hydro schemes

and monitoring the results. Practical Action in Nepal has plans

to field test the bursting discs in some existing micro-hydro

schemes.