CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

89

For buried penstock sections, a minimum soil cover of 1 m

is recommended as in the case of HDPE headrace pipe, and

the trench details should be similar to those shown in Figure

4.8 (Chapter 4).

6.3 Pipe materials

In Nepal the most commonly used penstock pipe materials are

mild steel and HDPE. Rigid or unplasticised PVC (uPVC) is

another option that has been used in other countries such as

Peru (see Chapter 10, Innovations) and Sri Lanka, but has not

yet been used in Nepal. Table 6.1

The decision as to which pipe material to use for the penstock

can be based on Table 6.1, especially in Nepal. When in doubt,

it is recommended that the designer undertake preliminary

designs for all pipe materials available and compare the costs.

To minimise costs, for long penstock alignments HDPE pipes

can be used for the upstream length where the head is

relatively low (see Box 6.1). Standard couplings are available

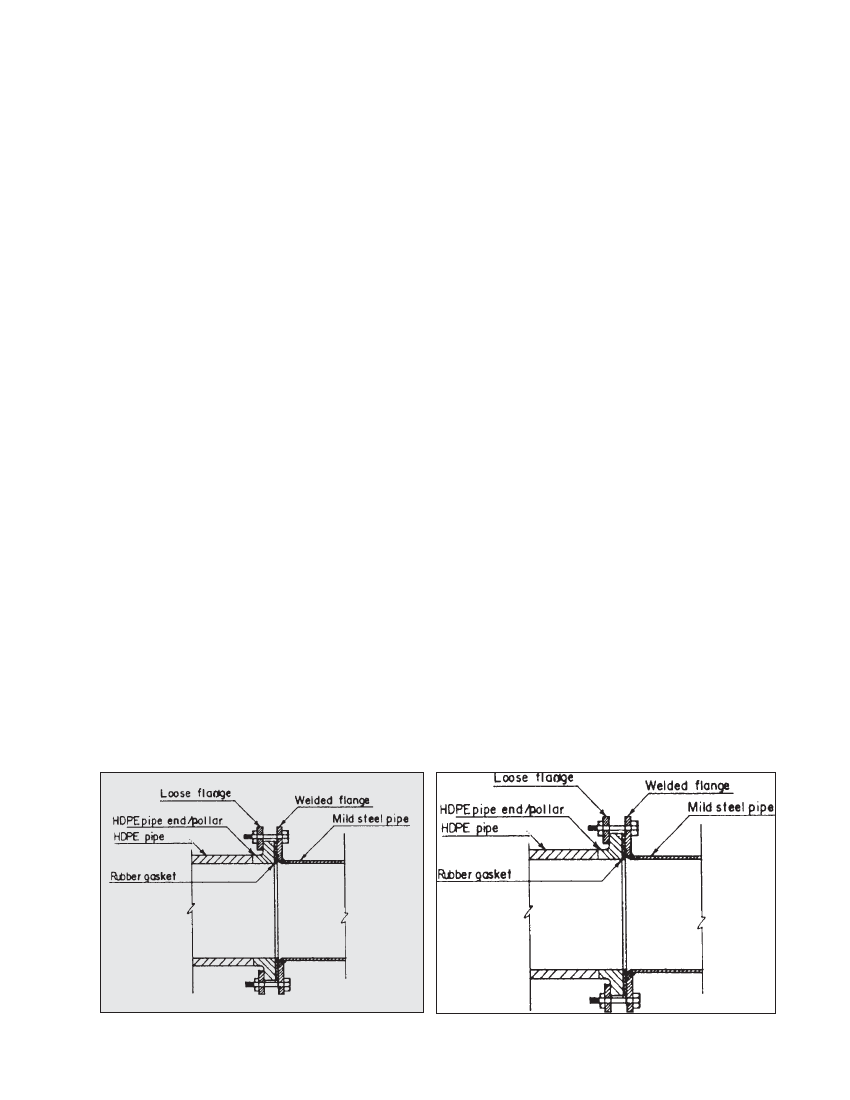

to join HDPE and mild steel pipes as shown in Photograph

6.6 and Figure 6.2.

Although steel pipe for micro-hydro in Nepal has normally

been specially manufactured locally, standard steel pipes may

be cheaper in some cases. Details of such pipes are given in

Appendix B.

6.4 Pipe diameter

Once the penstock alignment and pipe material have been

decided on, the design involves choosing the diameter and

pipe thickness. Selecting an appropriate pipe diameter is

discussed in this section and the wall thickness is discussed

in Section 6.6.

Note that with a few exceptions the sizing of the penstock

diameter is similar to that of a headrace pipe discussed in

Chapter 4. For simplicity, the entire penstock diameter selection

process is included in this section.

1. Choose a pipe size such that the velocity, V, is between 2.5

m/s and 3.5 m/s. In general, a velocity lower than 2.5 m/s

results in an uneconomically large diameter. Similarly, if the

velocity exceeds 3.5 m/s, the headless can be excessive and

hence uneconomical in the long run due to loss in power

output. Furthermore, higher velocities in the penstock will

result in high surge pressure as will be discussed later.

Note that compared to the headrace pipe, higher velocities

can be allowed in the penstock pipe since it conveys sediment

free water.

For steel penstocks, it may be economical to choose the

diameter so that there is no wastage from standard size

steel sheets. For HDPE or PVC, available sizes must be

selected. Pipes are normally specified by outside diameter,

so two times wall thickness must be subtracted to obtain

the internal diameter. Standard pipe sizes are given in

Appendix B.

2. Calculate the actual velocity:

V = 4Q / IId2

where:

V is velocity in m/s.

Q is design flow in m3/s.

d is the pipe internal diameter in m.

3. Calculate the headloss in the pipe length based on the

inlet, wall friction, bends, valves and exit loss as follows:

Total head loss = wall loss + turbulence losses / Wall losses

are calculated as follows: First determine the roughness value,

‘k’ in mm from Table 4.3 (Chapter 4). Then use the Moody

Chart in Figure 4.10 (Chapter 4)

Figure 6.2 Typical HPDE-mild pipe coupling

Photo 6.6 HDPE-mild steel coupling, Note that except for the final length,

the HDPE pipe is buried, Jhong micro-hydro scheme, Mustang, Nepal