42 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

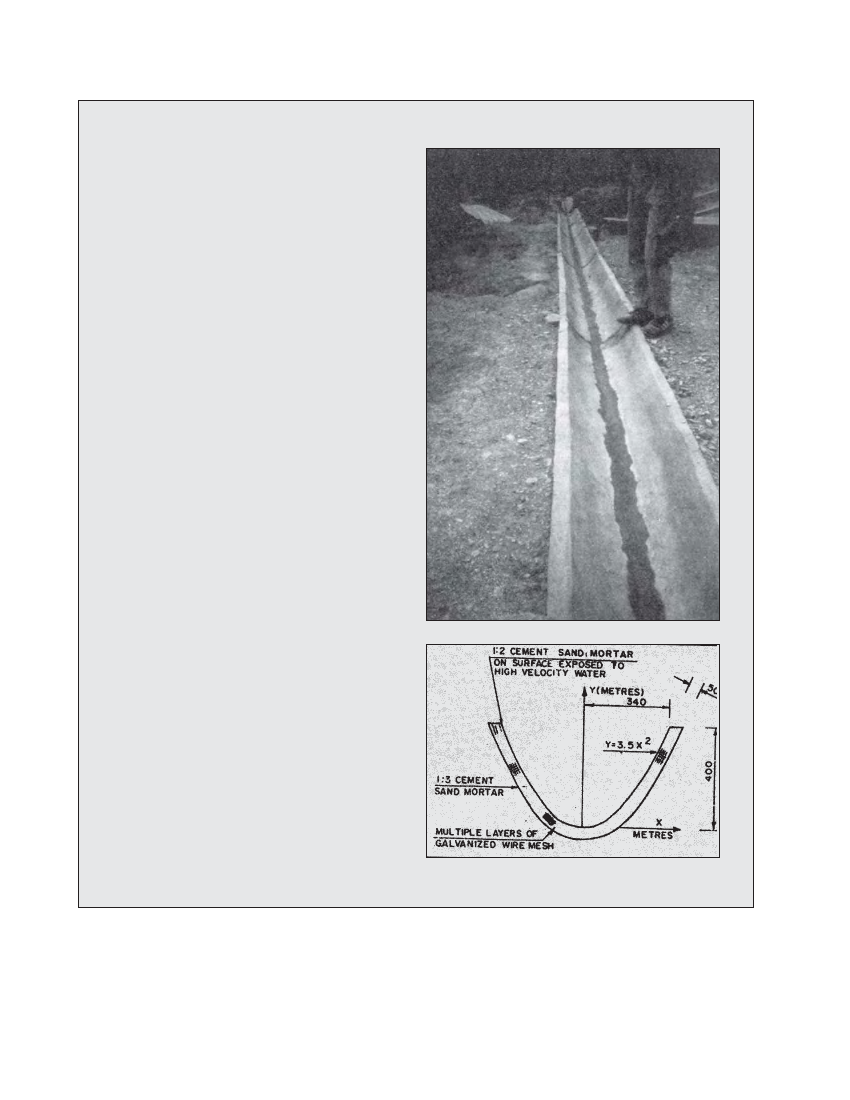

Box 4.2 The experience with ferrocement in Nepal

Ferrocement pilot projects have been promoted by the

Andhi Khola Irrigation Project (AKIP) and the International

Labour Organisation (ILO). Ferrocement structures are

made of thin cement sand mortar (1:2 to 1:3) with thin

steel mesh as reinforcement. ILO has used ferrocement

for lining irrigation canals in the Sindhuli Flood Rehabilita-

tion Project.

The ILO ferrocement canal cost was US$ 31 per linear

metre and the cement masonry design of similar ca-

pacity was US$ 28 (1989 prices). The ILO justifies the

additional cost by attributing it to better durability and

little maintenance which ferrocement canals require.

Other advantages are smooth finishing which reduces

head losses, resistance to abrasion, and very low seep-

age losses.

The ferrocement flume used in AKIP (designed by BPC

Hydroconsult) is shown in Photograph 4.6 and Figure

4.1. Galvanised sheets with intermediate steel frames

were used for the formwork. Multiple layers of 10 mm to

15 mm thick, 1:3 cement sand mortar were placed on

the formwork. The final inside layer (i.e. water retaining

surface) was prepared using a mix of 1:2 cement sand

mortar. Galvanised thin wire mesh (also known as

chicken wire mesh) was placed between each layer as

reinforcement.

The Andhi Khola ferrocement flume has been function-

ing well since its commissioning in 1993. This design

was more economical than the conventional stone ma-

sonry in cement mortar canal with drop structures. How-

ever, it should be noted that the construction of

ferrocement canals requires skilled and well trained

manpower (masons) to achieve the required quality of

work and therefore may only be justified where a very

long canal is to be installed in poor soils. Furthermore, if

skilled labour is expensive, ferrocement canals may cost

more than the conventional design, as in the case of

Sindhuli Flood Rehabilitation Project.

Photo 4.8 Andhi Khola Project ferrocement flume

Figure 4.1 Andhi Khola Project ferrocement flume