CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

85

6. Penstocks

6.1 Overview

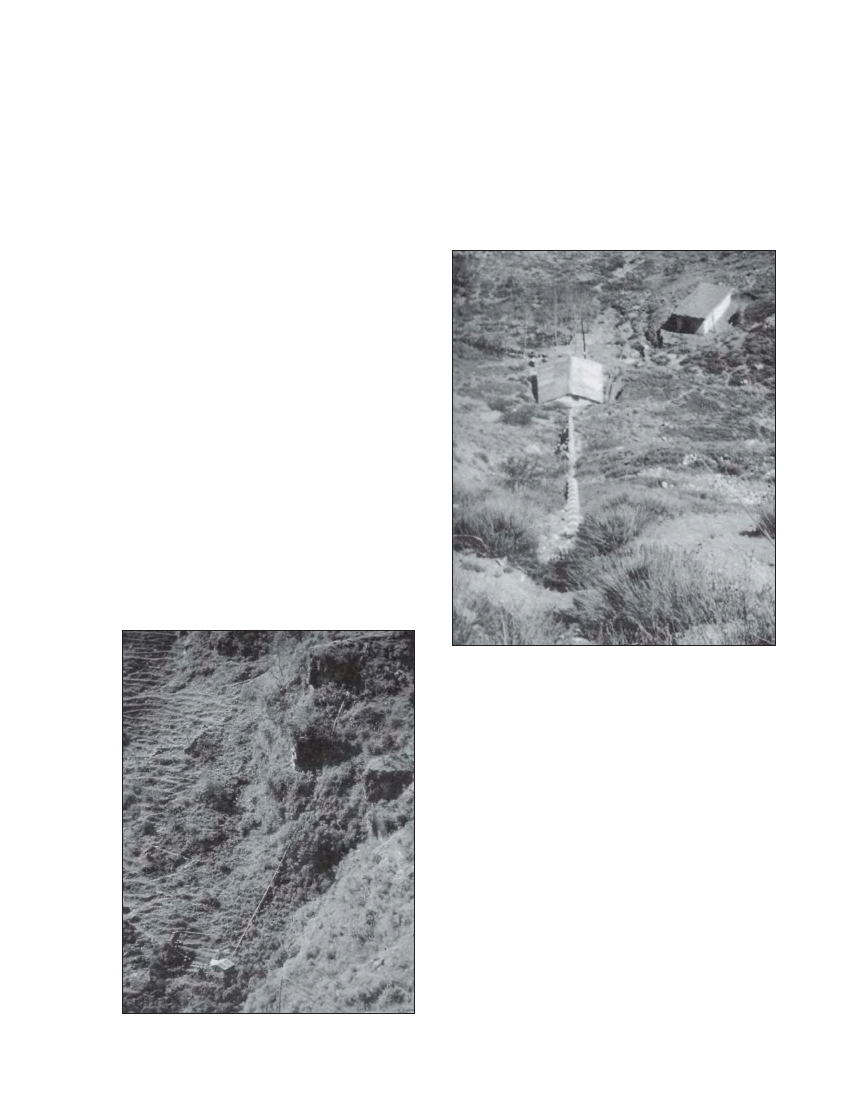

A penstock is a pipe that conveys the flow from the forebay

to the turbine. The penstock pipe starts where the ground

profile is steep as shown in Photograph 6.1. The penstock

pipe usually constitutes a significant portion of the total

micro-hydro construction cost. Therefore it is worthwhile

optimising the design. This involves a careful choice of:

pipe material, such as mild steel or HDPE; an economical

diameter such that the head loss is within acceptable limits;

and wall thickness so the pipe is safe for the design head

and any surge effect that may result from sudden blockage

of the flow. The potential energy of the flow at the forebay is

converted into kinetic energy at the turbine via the penstock

pipe. Since the flow is conveyed under pressure it is

important for the pipe design to be safe. Cases have been

reported where the penstock pipes have burst. Since the

penstock is on steep ground slopes, such pipe burst can

instantaneously cause landslides and other stability

problems. Furthermore, penstock installation is often

challenging and requires safe and careful work as shown in

Photograph 6.2.

Photo 6.2 Penstock alignment of the 50 KW Barpak micro-

hydro scheme, Gorkha, Nepal

Photo 6.1 Penstock alignment of the 36 kW Jharkot micro-hydro

scheme, Mustang. Nepal

6.2 Selection of the penstock alignment

6.2.1 SITE WORK

Selection of the penstock alignment at site should be based

on the following criteria:

Forebay location

The penstock starts at the forebay, for which location criteria

are given in Section 5.1.3. In addition, the forebay location

should be chosen to optimise the lengths of headrace and

penstock whilst achieving the required power output from

the scheme. Penstock pipe is generally more expensive than

headrace canal, therefore in most cases the forebay location

should be chosen to give the minimum penstock length.

However, sometimes a longer penstock may be economic, to

avoid the need for the headrace to cross an unstable slope.

Practical ground slope

An ideal ground slope for the penstock alignment is between

1:1 and 1:2 (V:H). The flatter the ground slope the less

economic is the penstock since a longer pipe length is required

for a lower head.