90 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

to find the corresponding friction factor f for the selected pipe

material, diameter and the design flow. The wall loss can now

be calculated from either of the following equations: ,

hwall loss

=

f

LV2

d x 2G

hwall

loss

=

fL x Q2

12d2

Turbulence losses are calculated as follows:

hturb

loss

=

V2

/29

(Kentrance

+

K+

bend

Kcontraction

+

Kvalve

)

where loss coefficients, K, are as shown in Table 4.4.

4. In general ensure that total head loss for the design flow is

between 5% and 10% of the gross head, i.e. 95% to 90%

penstock efficiency.

5. If the head loss is higher than 10% of the gross head, repeat

calculations with larger diameter. Similarly, if the head loss is

less than 5% the pipe diameter may be uneconomic, therefore

repeat calculations using smaller diameters.

Note that in exceptional cases a less efficient penstock may

be more economic, such as when the power demand is limited,

the penstock pipe is long and there is abundant flow in the

river even during the low flow season. In such cases, a higher

flow can be allowed in a smaller diameter pipe allowing a

higher head loss, which is compensated by the flow. Hence

savings can be made in the cost of pipes as discussed in Box

6.1. However, this approach should be justified by a detailed

economic analysis.

On the other hand for larger hydropower projects (mini/small

or large) the diameter of the penstock pipe is selected on the

basis of a detailed financial analysis. The process involves

calculating pipe costs and head losses for a range of diameters

and comparing these with the present value of energy losses

within the economic life of the power plant. As long as the net

present value remains significant (i.e., benefits outweighs

costs) the diameter is increased. Alternatively, for a given

diameter both the penstock pipe cost (and hence the total

project cost) and the cost of energy lost due to head loss can be

calculated. Then, the optimum penstock diameter would be

the diameter corresponding to minimum total costs as shown

graphically in Figure 6.2. It should also be noted that there

are generally other criteria as well, such as availability of steel

plate widths in the market, local fabricating capabilities

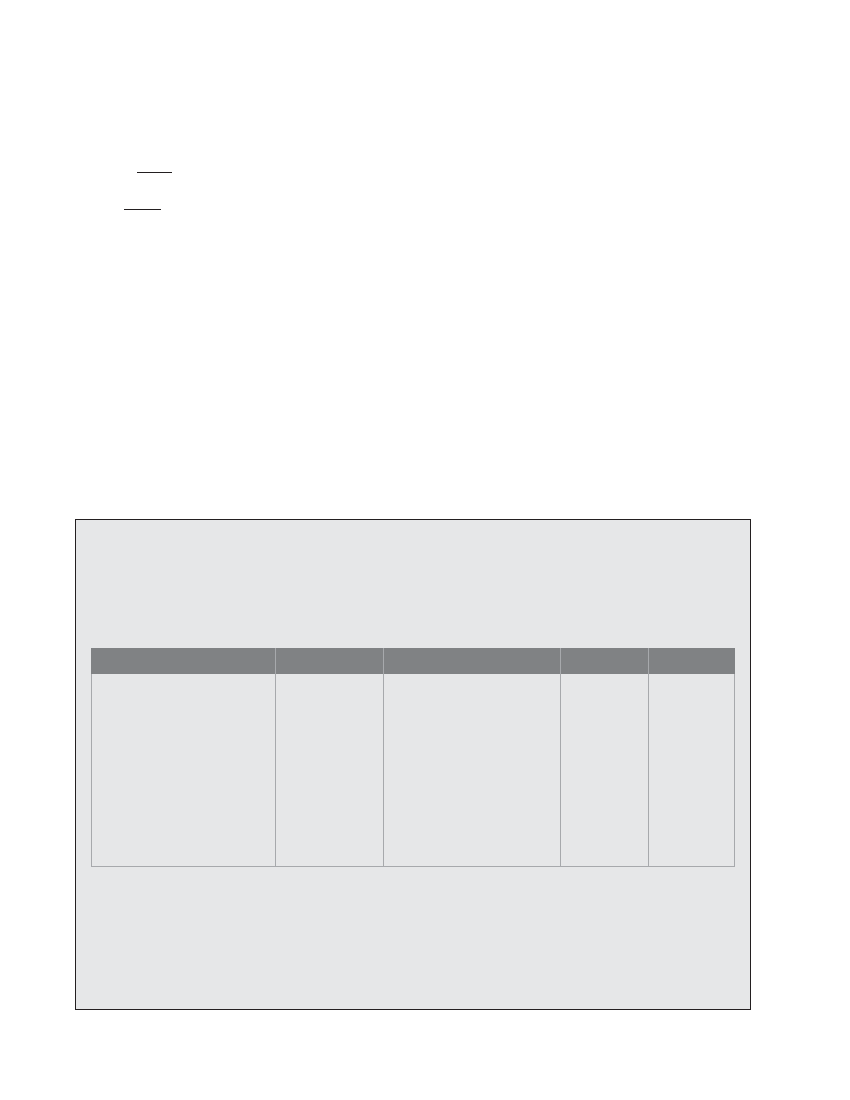

BOX 6.1 HDPE-mild steel penstock, Bhujung micro-hydro scheme, Nepal

The 80 kW Bhujung micro-hydro scheme (Bhujung, Lamjung, Nepal) designed by BPC Hydroconsult for Annapurna Conservation

Area Project (ACAP) is currently under construction. The design discharge of the scheme is 150 1/s, the total penstock length is

860 m and the gross head is 104 m. Since it is a long penstock, HDPE pipes are used for the initial length and mild steel pipe for

the downstream end as follows:

PENSTOCK TYPE (m)

THICKNESS (mm)

315 mm diameter, Class II HDPE

10.3

GROSS HEAD AT d/s END (m)

26.8

LENGTH (m)

310

HEADLOSS(m)

4.6

315 mm diameter, Class III HDPE

16.1

41.8 180 3.2

300 mm diameter, mild steel

3

64.8 260 3.5

300 mm diameter, mild steel

4

103.9

110 1.5

Total headloss

12.8

% headloss

12.3%

Note that the total head loss is about 12%: though more than 10%, in this case a higher headloss was found to be economic.

This is because the estimated power demand for the village is 80 kW and the source river (Midim Khola) of the scheme has

significantly higher flows, even during the low flow season (minimum flow of 0.5 m3/s in April) than the required design discharge.

If the penstock pipe diameter was sized for less than 10% headloss (i.e. by increasing the diameters and decreasing the design

discharge such that power output = 80 kW), the pipe cost including laying and transportation would have increased by 15%.

Similarly if mild steel was used for the entire alignment (for headloss = 12%), the pipe cost would have increased by about 30%.

Note that settling basin and headrace costs need to be included in the optimisation.