CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

113

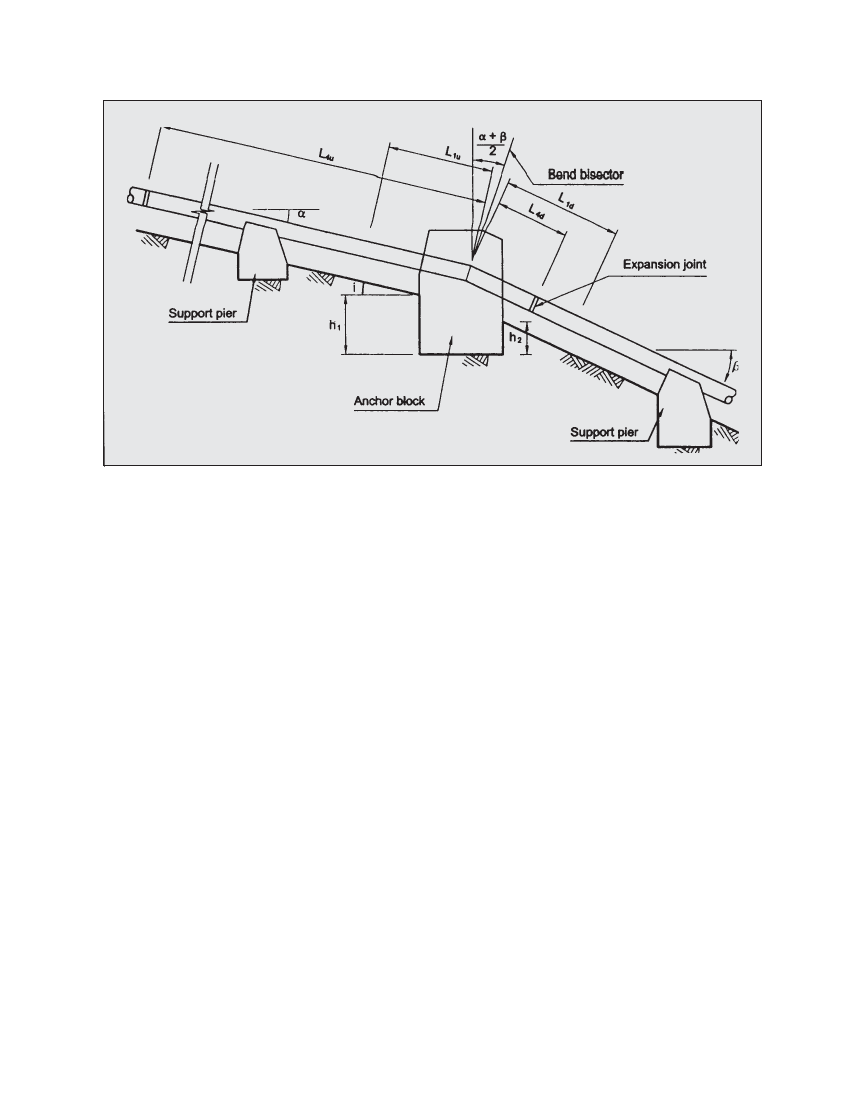

Figure 7.5 Distances and angles used in anchor block and support pier equation

7.4.2 DESCRIPTION OF FORCES

F1 - F1 is the component of the weight of pipe and enclosed

water perpendicular to the pipe alignment. If there is a bend

at the anchor, however, both the upstream and downstream

lengths of pipe contribute separately, each force perpendicular

to the centreline of the pipe segment which contributes to it.

F2-F2 is the frictional force of pipe on support piers. If the

penstock moves longitudinally over support piers, a friction

force on the pipe is created at each pier. A force “F2”, equal to

the sum of all these forces but opposite in direction, acts on

the anchor. This force exists only where one or more support

piers are located between the anchor block and an expansion

joint. For example, if an expansion joint is located immediately

downhill of the anchor, friction forces on the downhill length

of pipe will not be transmitted to the anchor block from that

side. The friction coefficient, f, depends on the material

against which the penstock slides and is as follows:

steel on concrete, f = 0.60

steel on steel, rusty plates, f = 0.50

steel on steel, greased plates or tar paper in between, f = 0.25

F3 - F3 is the force due to hydrostatic pressure within a bend.

The hydrostatic pressure at a bend creates a force which acts

outward for upward bends and inward if the bend is down-

ward. This is a major force which must be considered in

designing anchor blocks. However, the block size can be

significantly reduced if the bend angle (β - α) can be

minimised while fixing the penstock alignment.

F4 - F4 is the force due to the component of the weight of pipe

parallel to the pipe alignment. On a slope, the component of

the weight of the pipe which is parallel to the pipe tends to

pull it downhill and exerts a force on an anchor block. The

sections of pipe both upstream and downstream of an anchor

block may have to be considered. The lengths ‘L4u’ and ‘L4d’ in

the equation for the force “F4” acting on an anchor block are

the lengths of the upstream or downstream section of the

penstock which is actually to be held by that block. The

upstream section may begin at the forebay or, more usually, at

an expansion joint. The downstream section usually ends at

an expansion joint. If the expansion joint downstream of an

anchor block is located near the anchor, as it usually is, the

force arising from the weight of the downhill section of pipe

between the anchor and the joint is insignificant and is

usually neglected. Also, the anchor block will not experience

this force if the penstock is buried since the ground friction

will resist this force.

F5 - F5 is the force that is transmitted to the anchor block due

to thermally induced stresses in the absence of an expansion

joint. If an exposed section of a rigid pipe does not incorporate

an expansion joint, thermally induced stresses build up in

the pipe and act on the anchor block. The associated force

“F5” may push against the anchor block (with increasing

temperature) or pull the anchor block (with decreasing

temperature).

F6 - F6 is the force due to friction within the expansion joint.

To prevent leaking, the packing within an expansion joint

must be tightened sufficiently. However, this tightening also

makes it more difficult for the joint to accept any longitudinal

movement of the pipe. Friction between the packing and the

concentric sleeves in the expansion joint creates a force “F6”

which opposes any expansion or contraction of the pipe. This

force is dependent on pipe diameter, tightness of the packing