82 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

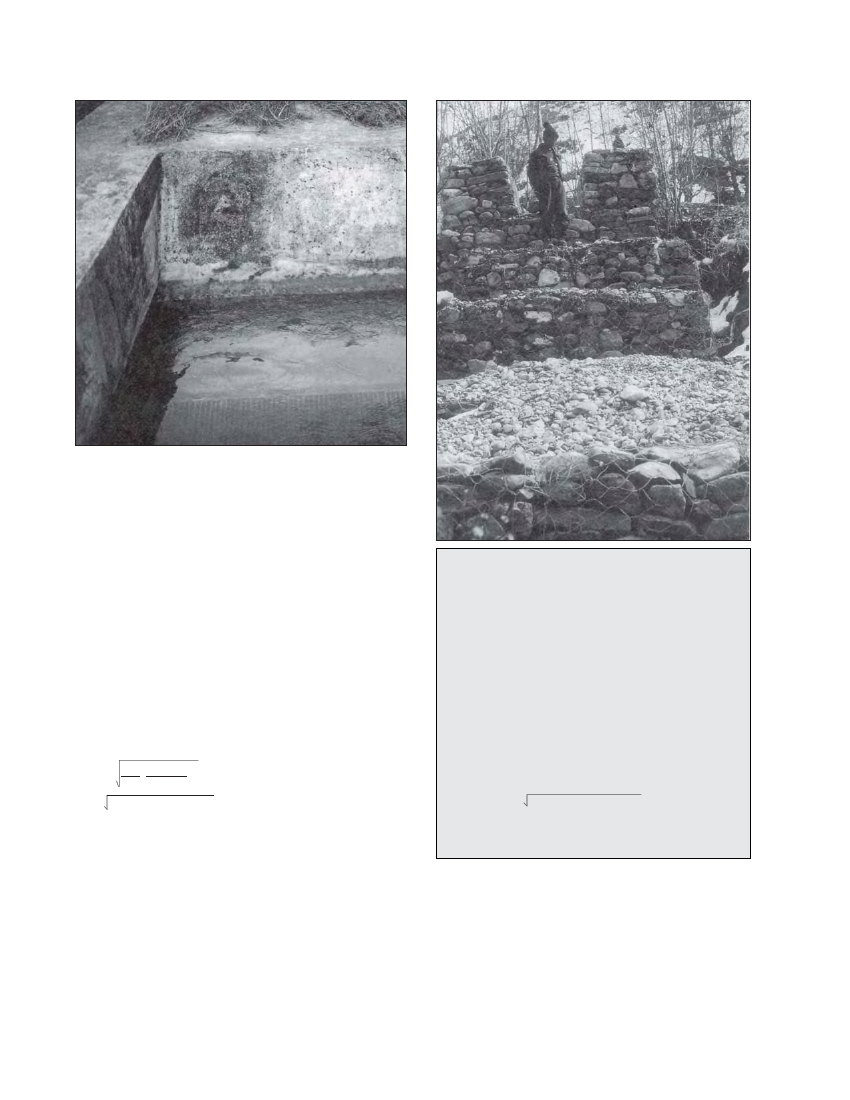

Photo 5.12 Submerged trashrack, Salleri Chialsa mini-hydro scheme

through the air intake pipe and into the penstock.

The required size of the air vent is given by:

d2 =Q or

F/E ( D / teffective )3

where:

d = internal diameter of air vent (mm)l

Q = maximum flow of air through vent (l/s)

= maximum flow of water through turbine

E = Young’s Modulus for the penstock (N/mm2, see Table

6.2)

D = Penstock diameter(mm)

teffective = effective penstock wall thickness at upper end

(mm) (refer to Section 6.6)

F = safety factor, 5 for buried pipe or 10 for exposed pipe.

dr = Q

( )F D 3

E teffective

5.5 Construction of water retaining

structures

Once the size of the gravel trap, settling basin and forebay

have been calculated, the type and dimensions of the walls

and floors need to be determined. For micro-hydro schemes,

stone masonry in cement mortar is generally the most

appropriate and economic option. The construction details

and procedures for this type of structure are as follows:

The ground should first be excavated according to the basin

shape and then be well compacted using a manual ram.

Since these are water retaining structures, 1:4 cement sand

mortar should be used for the walls and floors as discussed

Example 5.2 Sizing of air vent

Consider a 300 mm steel penstock of 3 mm wall thickness

connected to a turbine that can take 2501/s. The penstock

is above ground.

Q = 250 1/s

E = 2.0 x 105 N/mm2 (from Table 6.2)

D = 300 mm

t = 3mm

teffective = 1.27 mm (from Section 6.6)

F = 10 for above ground pipe

Then d2 = 250 10 / 2x105(300 / 1.27)3

Or, d = 80 mm, i.e. the minimum internal diameter of the air

vent should be 80 mm.

in Chapter 4.

The walls should be built such that they are a minimum

of 300 mm thick at the top and increase with depth as

shown in Figure 5.9. Note that in this figure, the wall

surface on the water retaining side is vertical. This

increases the stability of the structure since for a constant

depth the water pressure is larger than the soil pressure.