CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

125

Equivalent distance at which ΣV acts from point B:

d = ΣM /ΣV = 282.5 / 260.5 = 1.08m

eccentricity,

e = (Lbase / 2) - d

e = (3.2 / 2) - 1.08

e = 0.25m

eallowable

= Lbase / 6 = 3.2 / 6 = 0.53 m

Since e is less than eallowable , eccentricity is in the middle third.

... The structure is safe against sinking.

Check bearing pressure :

Pbase

= ΣV/Abase [1 + 6e/Lbase ]

= [260.5 / (3.2 x 2.5)][1+ (6x0.52)/3.2]

= 64.3 kNm-2 < 180 < kNm-2 (max. allowed for soil)

... The structure is safe against sinking.

Check sliding:

Assume that the friction coefficient between block and soil, µ = 0.5

ΣH = FH = 70 kN

µΣV = 0.5 x 260.5 = 130.2 kN

Factor of safety against sliding :

= µ ΣV /ΣH = 1.86 > 1.5

... The structure is safe against sliding.

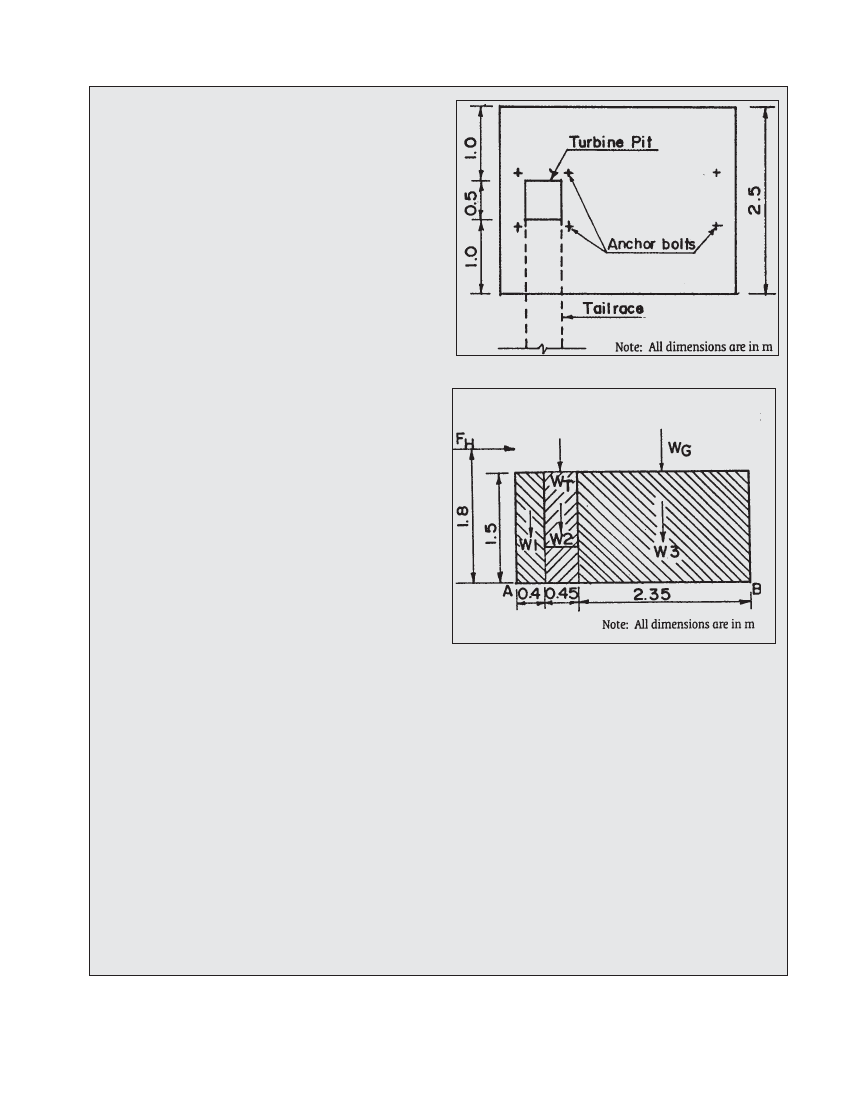

Figure 8.3 Machine foundation plan

Figure 8.4 Resolution of forces on the machine foundation

Hence, the structure as designed is adequate. The final design

including the reinforcement bars can be seen in Figure 8.5. A

1:1.5:3 mix concrete with reinforcement pattern as shown in the

figure is recommended for the machine foundation since the

structure must be rigid and strong enough to withstand the

forces. A 50 mm cover (clear spacing between the bars and the

edge of the concrete surface) should be provided for tine rein-

forcement bars. Such cover provides protection for the rein-

forcement bars against corrosion and other adverse effects.

Note that as can be seen in Figure 8.5, a 100 mm width of sand

and gravel has been placed at the periphery of the machine

foundation down to the depth of the powerhouse floor. This will

structurally isolate the machine foundation from the power-

house floor so that the dynamic forces (such as vibrations)

are not transferred to the floor and walls. Cracks along the

powerhouse floor and walls have been observed where the

machine foundations have not been structurally isolated. The

50 mm thick bituminous surface prevents the gravel and sand

from being compacted (and hence the possibility of transfer-

ring forces to the powerhouse floor). This is done by pouring

hot bitumen (as used in black topped roads). The 50mm thick

concrete blinding provides an even surface for reinforced

concrete work of the machine foundation. Also note that, if a

belt drive system is required, the machine foundation should

be extended to cover it. However, the depth of foundation for

the belt drive can be lowered to 300 mm but with similar

reinforcement pattern.