62 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

TABLE 4.3 Roughness value for different pipe materials

MATERIAL

ROUGHNESS VALUE, k (mm)

Smooth pipes

PVC.HDPE, MDPE, Glass fibre

0.06

Concrete

0.15

Mild steel

- Uncoated

- Galvanised

0.06

0.15

5. Check if the total head loss for the design flow is less than

the loss in head due to the pipe gradient (S) and that the

pipe profile is below the hydraulic grade line everywhere.

If not, repeat calculation with larger pipe diameter.

6. Determine the water level at the control structure

at the end of pipe such as the break pressure tank,

gravel trap or the settling basin. Allow 10% margin by

assuming that the total head loss is 10% higher than

calculated (i.e. water level is 10% lower than calculated).

This is to allow for uncertainties such as the wall losses

being higher than assumed.

7. Repeat calculations with higher submergence head

due to flood flows and calculate the corresponding

losses and pipe flow. The excess flow will have to be

spilled from a control structure (gravel trap, settling

basin etc.) at the end of the pipe.

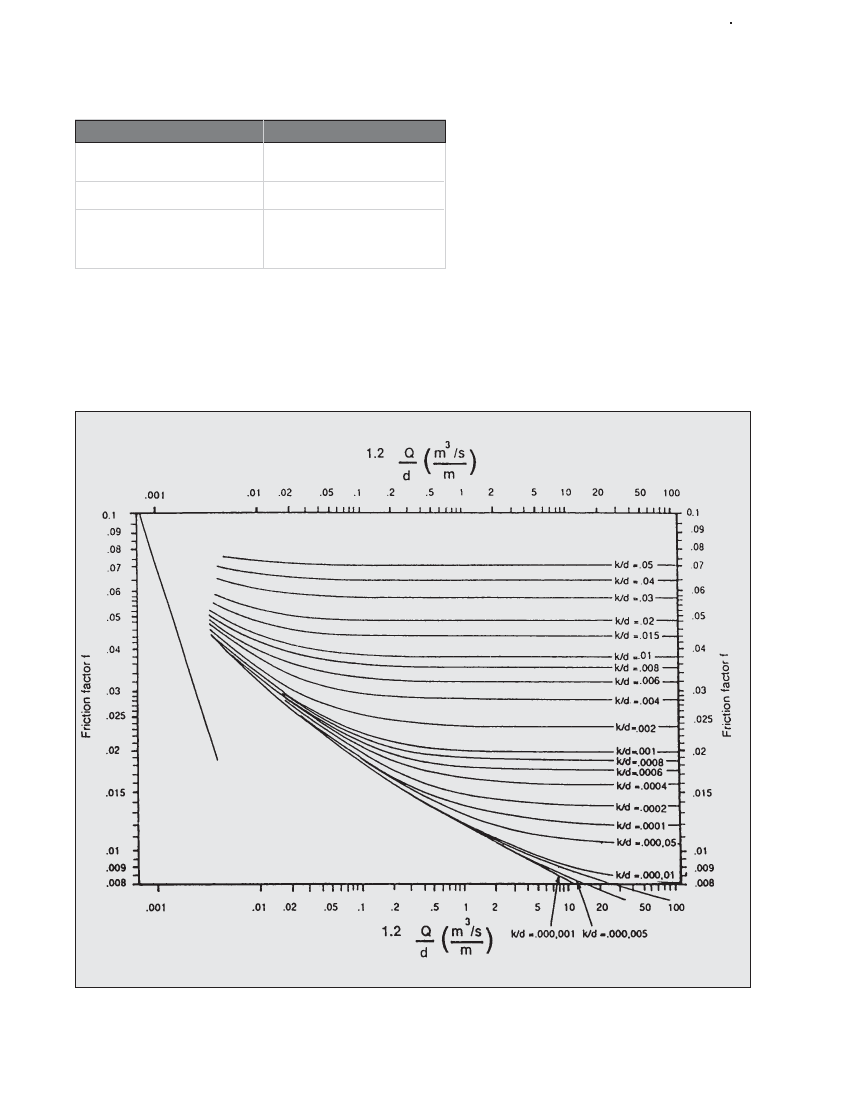

Figure 4.10 Moody chart