CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

139

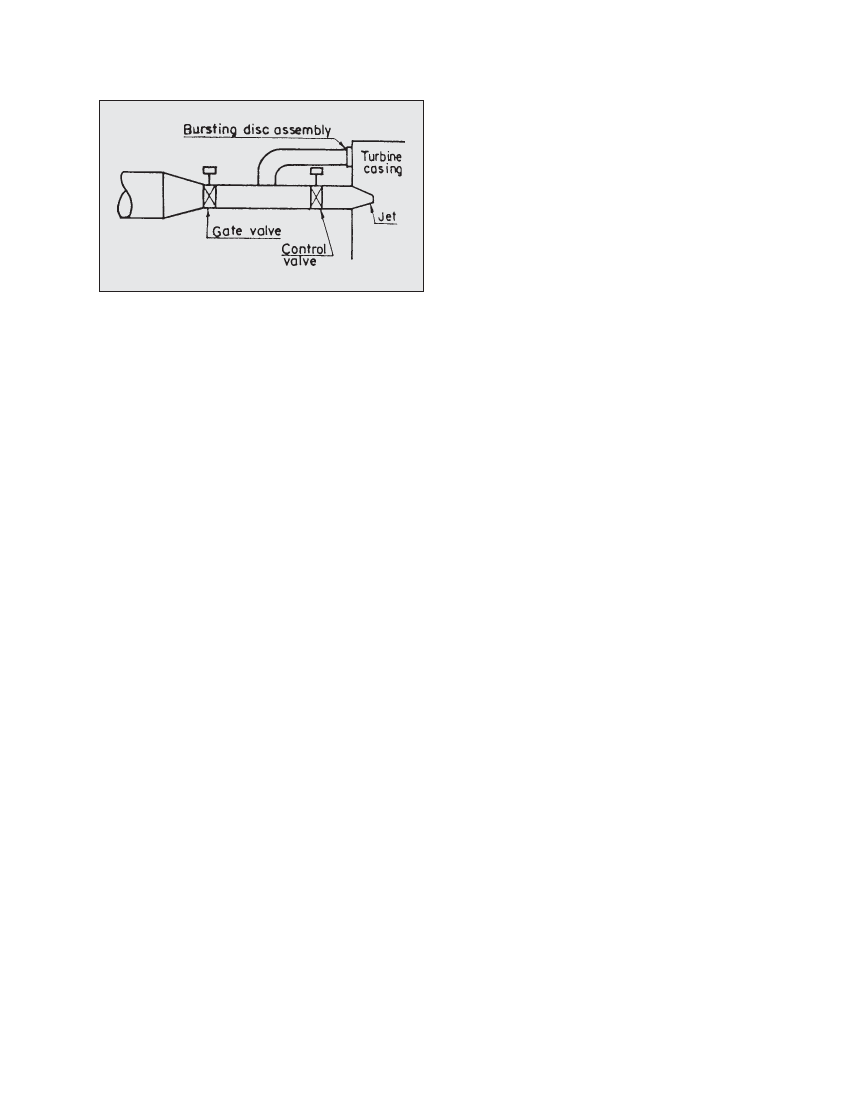

Figure 10.2 Proposed arrangement for bursting disc installation in

micro-hydro schemes

More information on the applicability of bursting discs for

micro-hydro schemes can be obtained from Dulas Limited

(same address as above).

Information on commercial bursting discs can also be obtained

from the following manufacturer:

IMI Marston Limited

Wobaston Road, Fordhouses,

Wolverhampton WV106QJ

England, UK

Fax: +44 (0) 1902 397792

10.5 Flexible steel support pier for Jharkot

micro-hydro

The 36 kW Jharkot micro-hydro scheme is located in Mustang

District, Nepal. This is a community owned scheme and is

managed by the Jharkot Electrification Committee. Practical

Action in Nepal has been involved in providing technical

support for refurbishment work of this scheme for some time.

Similar to other areas of Mustang, the topography of the project

area consists of fragile and unstable slopes and is prone to

landslides. The intake and the initial headrace canal have

been damaged frequently by landslides and floods. Although

the slope along the penstock alignment is relatively stable

compared to the intake area, it is weak and also prone to

landslides. The existing masonry support piers started sinking

due to their own weight as well as the weight of the penstock

pipe and the water inside it. Hence, the penstock (flange

connected) started to sag at various places. As part of the

preparation of this text, a pilot project was carried out to design

and install steel support piers for the Jharkot scheme with

assistance from Mr. Shyam Raj Pradhan of NYSE. The design

criteria were as follows:

The support pier had to be light, to minimise self weight.

It had to be fabricated using parts that could be carried by

porters or mules. Jharkot is about half a day’s walk from the

district airport and 5 days’ walk from the nearest roadhead.

The design had to allow for the sinking of the foundation.

In case of sinking of the ground below the foundations, the

piers should not pull the penstock pipe down along with it.

The design of the support pier and the foundation are shown

in Figures 10.3 and 10.4 respectively. The total weight of a 2

m support pier is 60 kg (excluding the foundation work)

whereas a masonry pier of similar height would weigh 4000

kg. Note that such support piers should be installed

perpendicular to the penstock alignment (not vertically) since

they are only resisting force Fj (see Chapter 7). The top section

of the pier consists of a channel which is pin connected to two

legs that have turnbuckles. The penstock pipe rests on the

channel and the pin connection allows the channel some

rotation such that it is perpendicular to the penstock alignment.

Two holes have been provided on the channel to clamp the

penstock with a 12 mm diameter bar. The turnbuckles can be

adjusted to fine tune the height of the support piers (up to

300 mm) during installation and in case the foundation sinks

in the future. The bottom of the turnbuckles (40 mm rods) fit

inside a hollow pipe as shown in Figure 10.3. In case the

ground beneath the foundation sinks, the support pier

structure below the turnbuckles drops down along with the

foundation and only the top part (up to the turnbuckle legs)

hangs with the penstock. Hence the penstock pipe is not

dragged down with the pier in case of sinking. The bottom

part of the pier consists of angles which are bolted back to

back (Figure 10.3). Bolt holes at a distance of 150 mm are

provided for coarse adjustment of the pier. The bottom angles

are pin connected to the foundation so that the moments due

to thermal expansion of the penstock pipe are not taken by

the support pier or the foundation.

During installation as well as later in case the foundation sinks,

coarse adjustment can be made using the bolt holes of the bottom

angles and then fine tuned using the turnbuckles at the top. The

top and bottom parts of the pier have fixed heights. The length of

the middle portion (angles bolted to channels) is varied such

that the total pier height is equal to the required height. Note

that this support pier can be dismantled such that there are 12

individual pieces (including the 12 mm stirrup bar to connect to

the penstock). 18 support piers ranging from 1.0 m to 2.6 m

height have been fabricated based on this design. To ensure

that the support pier would function well, one (2.5 m total height)

was tested at the manufacturer’s workshop (NYSE) as shown in

Photographs 10.7 and 10.8. About 500 kg of axial load

(maximum compressive load expected on the pier) was applied

on the pier. There was no observable effect on the pier

(deformation or deflection of angles) during the test of about 2

hours. It was even possible to raise the height of the pier by

rotating the turnbuckles with the full test load of 500 kg.

As of July 1998, all 18 support piers have been installed at the

Jharkot scheme. Their performance is currently being monitored.