108 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

Notes:

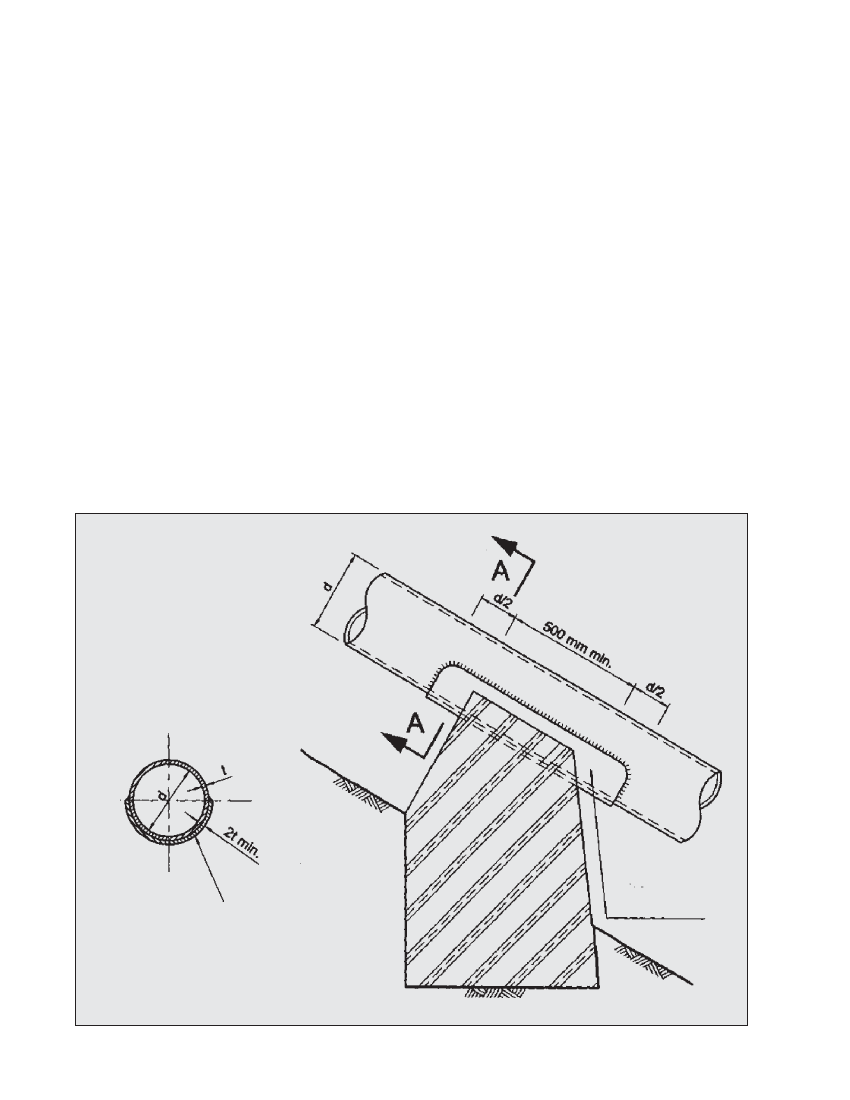

1. Applies only to steel penstocks welded or flanged to British Standard (minimum flange thickness = 16 mm). In other cases

use one support pier for each individual pipe length, with the pier in the middle.

2. Wear plates to be of some thickness as pipe wall , and weilded an all edges, covering bottom 1800 of pipe. The length should

be enough to extend at least 0.5 times the pipe diameter beyond each side of the support pier. See figure 7.3

3. For the calculation of teffective refer to Section 6.6.

4. Interpalate between the above values for intermediate pipe diameters, wall thickness or steel grades.

7.3.2 CONSTRUCTION OF SUPPORT PIERS

Support piers are generally constructed out of stone masonry

in 1:4 cement mortar. Dressed stone should be used for the

outside surfaces of the pier. A 140° bearing area from the

centre of the penstock diameter should be provided to support

the penstock pipe as shown in Figure 7.4. Placing a steel

saddle plate above the support pier where the penstock pipe

rests along with a 3 mm thick tar paper as shown in Figure 7.4

minimises frictional effects and increases the useful life of

the pipe. C-clamps may also be provided to protect the pipe

from vandalism and a sideways movement, but there must

be a gap between the surface of the pipe and the C-clamp, so

that axial forces are not transferred to the support pier. Stone

masonry support piers with C-clamps can be seen in Photograph

7.5.Wooden support piers have occasionally been used in

micro-hydro schemes, as can be seen in Photograph 7.7.

However, wood is generally expensive and also requires

frequent maintenance such as painting.

Steel support piers can also be used as an alternative to stone

masonry, especially at sites where cement is expensive or the

soil is weak in bearing. An example of steel support piers is

included in Chapter 10 (Innovations).

Figure 7.3 Arrangement of wear plate at support pier