102 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

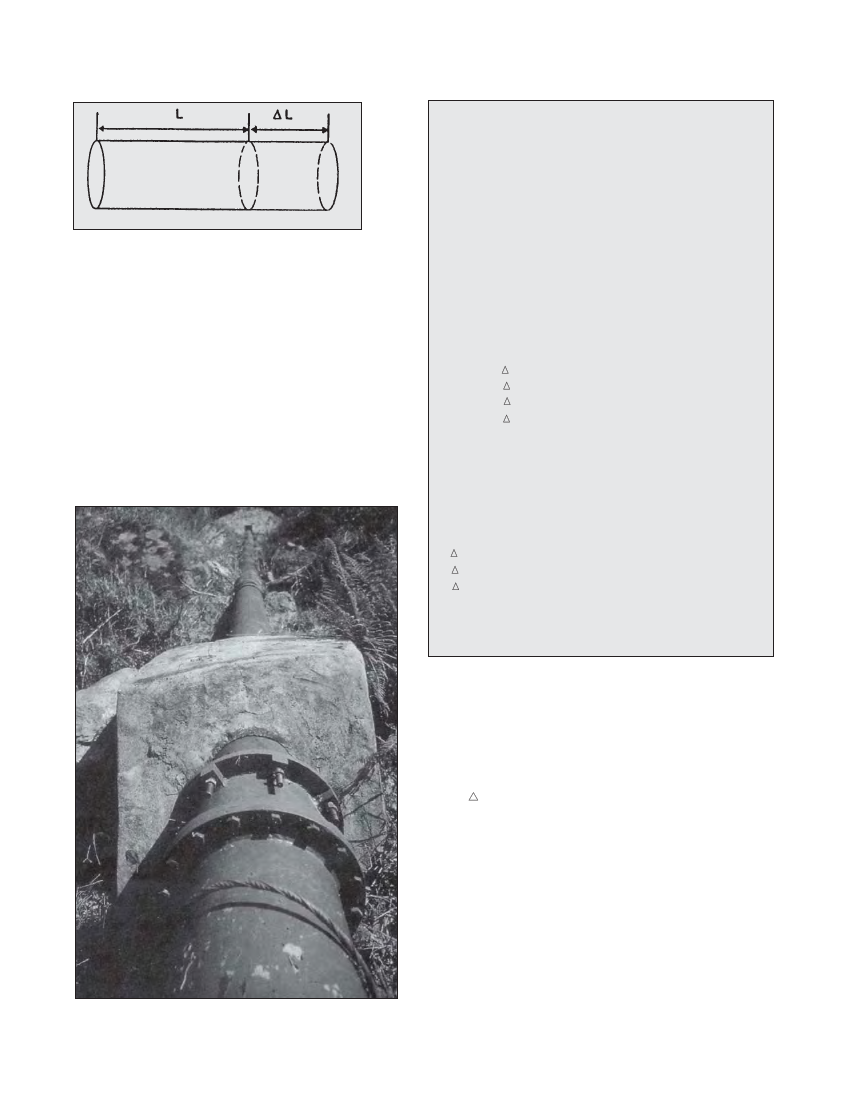

Figure 6.7 Thermal expansion of a penstock pipe

temperature. Different materials expand at different rates.

The values of this coefficient for mild steel, HDPE and PVC

are shown in Table 6.2.

Thot = highest temperature in °C that the pipe will experience.

Note that this can even be during mid-summer afternoon

when the pipe is empty (either during installation or repair

work).

Tcold = lowest temperature in °C that the pipe will experience.

This can be during winter when the water temperature is just

above the freezing point. Note that if freezing temperatures

are expected, the pipe should either be emptied or provision

Example 6.3 Calculating penstock pipe

expansion length

A mild steel penstock pipe is 45 m long between the forebay

and the first anchor block. The steel temperature during

installation was 40°C, and the expected lowest temperature

during the operational phase is 4°C during winter. What

expansion gap should be recommended to the manufacturer?

Also, if the temperature during installation is 20°C, what gap

should be provided?

α = 12 x 10-6 m/m °C

Thot = 40 ° C

Tcold = 4 ° C

L = 45m

L = a(Thot-Tcold)L

or L = 12 x 10-6 (40 - 4) x 45

or L = 0.019m

or L = 19 mm

Therefore minimum recommended expansion gap

= 19.4 x 2 = 38.8 mm, say 40 mm.

If the temperature during installation is 20°C

L = 12x1O-6(40-20) x 45

or L = 0.011 m

or L = 11 mm

Therefore, during installation an expansion gap of 11 mm x

2 = 22 mm should be provided.

should be made for constant flow. If the water in the penstock

stagnates during freezing temperature, ice will form inside

the pipe and could burst it, because when water freezes, the

volume expands. L = pipe length in m. Since it may be difficult

to determine when the expansion joint will be installed at

site, the manufacturer should be asked to allow an expansion

gap of 2 L Then, during installation, the temperature should

be noted and the gap left accordingly.

Photo 6.12 An expansion joint should be located just below an

anchor block to protect the block from forces which it may not be

designed to resist (Siklis)

6.11 Painting

Since mild steel pipes are subjected to corrosion, appropriate

coats of paint should be applied before dispatching them to

site. Proper painting of mild steel pipes significantly increases

their useful lives.

The pipes should be sand blasted if possible, otherwise they

should be thoroughly cleaned using a wire brush and a piece

of cloth. Prior to painting, the pipe surface should be clean

from oil, dust and other particles. When applying subsequent

coats of paint, the previous coat must be dry.