CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

137

iv. During steady state when the turbine was under

operation, the water depth in the chamber remained

below the toe of the screen. Thus, the submergence

depth set initially seemed to be adequate.

v. The water level inside the forebay chamber decreased

by 400 mm compared to the previous case, thus

decreasing the gross head by about 0.7 percent.

Although, the Cha Khola plant has faced intermittent problems

with the generating equipment, to date the screen is

performing satisfactorily.

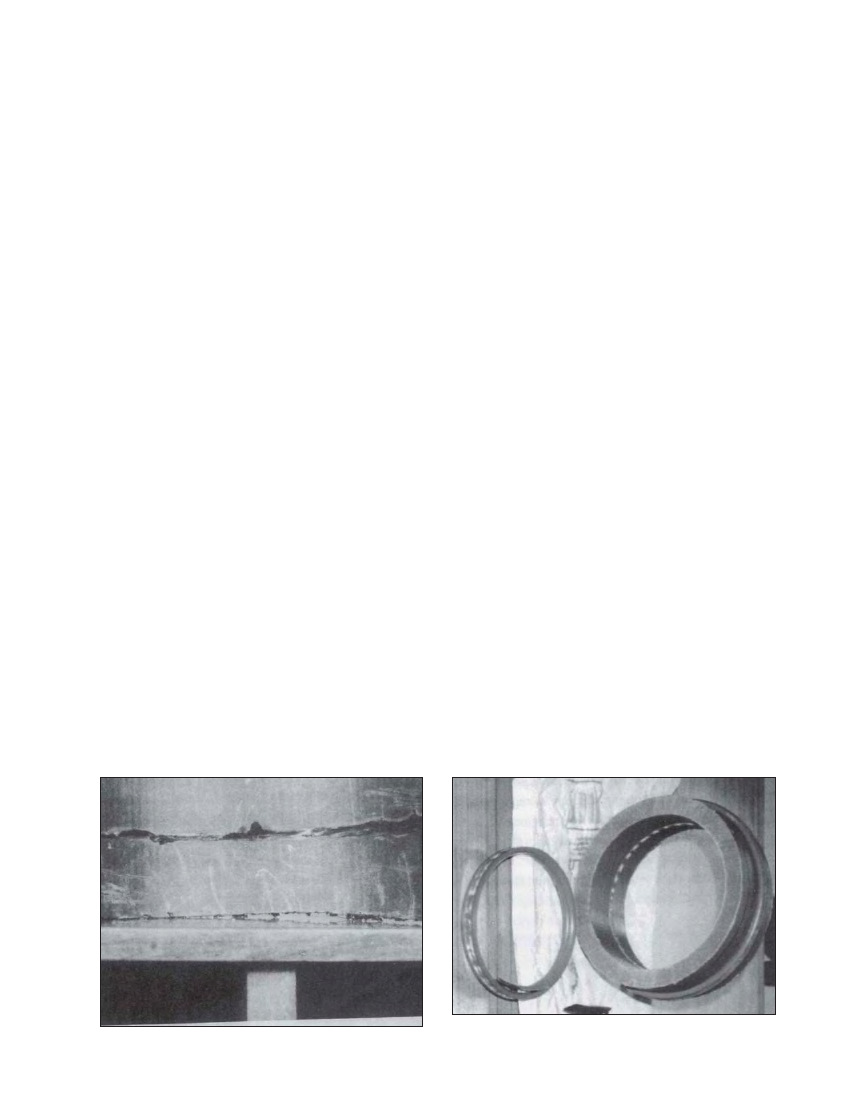

10.3 De-beader for HDPE pipes

As discussed in Chapter 4 (Box 4.7), HDPE pipes are joined by

heat welding which melts and fuses the ends together. This

leads to raised “beads” on the inside and outside of the pipe

as shown in Photograph 10.2. The external bead is not a

problem but the internal bead promotes blockages and

significant head loss. An effective debeader would reduce

the roughness value for HDPE from 0.06 mm (Table 4.3) to

0.03 mm.

A “debeader” tool has been designed (for IT Nepal) to remove

the internal beads from HDPE pipes while the joints are still

hot (i.e., hot debeading). This equipment has been designed

to remove beads for pipe diameters up to 250 mm. It is still in

the experimental phase and requires some development for

use in the field.

As shown in Photograph 10.3, the debeader consists of a

mild steel shaft with a sleeve on which a bush spring loaded

to a locking collar (via an Alien key) is placed. There are three

hardened steel blades (cutter arms) that are pin connected by

rectangular steel bars to the bush. By unlocking the bush the

connecting pin can slid up the sleeve to increase the cutting

diameter.

Debeading with this tool is done by first unlocking the bush

so that the tool can fit inside the pipe. A mild steel rod with a

handle is connected to the debeader such that the handle

sticks out of the pipe. The rod is supported by a number of

mild steel discs inside the pipe (smaller than the HDPE pipe

diameter) for lateral stability. The de-beader is then placed

inside of the pipe such that it is about 100 mm in front of the

proposed joint. The radius of the cutting arms are then

arranged by sliding the bush such that the blades are in

contact with the inside pipe surface. Once the blades snugly

fit on the pipe surface, there is a clicking sound indicating

that the cutting arms have been locked. As soon as the two

pipe ends are joined by heat welding as discussed in Chapter

4, the debeader is pushed forward till the blades come in

contact with the beads. The handle is then turned and the

debeader is pushed forward which removes the bead.

This de-beader was tested at Nepal Yantra Shala Energy,

Kathmandu, on a 200 mm pipe as shown in Photograph 10.4.

Debeading was tried on a joint about 2 m from one end of the

pipe. The test was partially successful. It was not possible to

remove the entire strip of the bead. Part of the bead and some

thin strands were left on the joint, as can be seen in

Photograph 10.4.

The following observations were made in the workshop:

The major constraint was that the radius of the cutter blades

is fixed and the blades do not work equally well on all pipe

diameters within the range.

If debeading is not started immediately after the pipes are

joined (i.e. within 30 seconds), the beads cannot be

removed.

The turning of the handle and pushing of the de-beader

has to be controlled. A sudden jerk pushes the de-beader

beyond the joint.

The debeading process is also hampered if the pipe ends

are not totally circular.

Photo10.4 HDPE pipe joint de-beaded using the de-beader

Photo10.5 HDPE pipe joint de-beaded using a commercial de-beader.

The small ring in front of the pipe section is the bead.