CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

107

7.3 Support piers

73.1 GENERAL

Locations at which support piers are required and their

construction are described in this section.

73.2 LOCATION OF SUPPORT PIERS

Support piers are required along the straight sections of exposed

penstock between anchor blocks. The maximum spacing of

support piers to avoid overstressing the pipe is given in Table

7.1. Please read the notes under the table. Thin-walled plain

pipe can buckle at the support piers with relatively short spans.

In this case the permissible span can be increased by welding

a wear plate to the pipe at each support, see Figure 7.3. This

may be economical for pipes larger than 300 mm diameter.

Corners of wear plates should be cut with a radius, to avoid

stress concentrations. Note that a wear plate is also required

where the pipe leaves an anchor block, if the span to the first

support pier exceeds that allowed for plain pipe. It is usually

not economical to increase the pipe wall thickness in order to

increase the support pier spacing, but this should be considered

where the cost of support piers is significant.

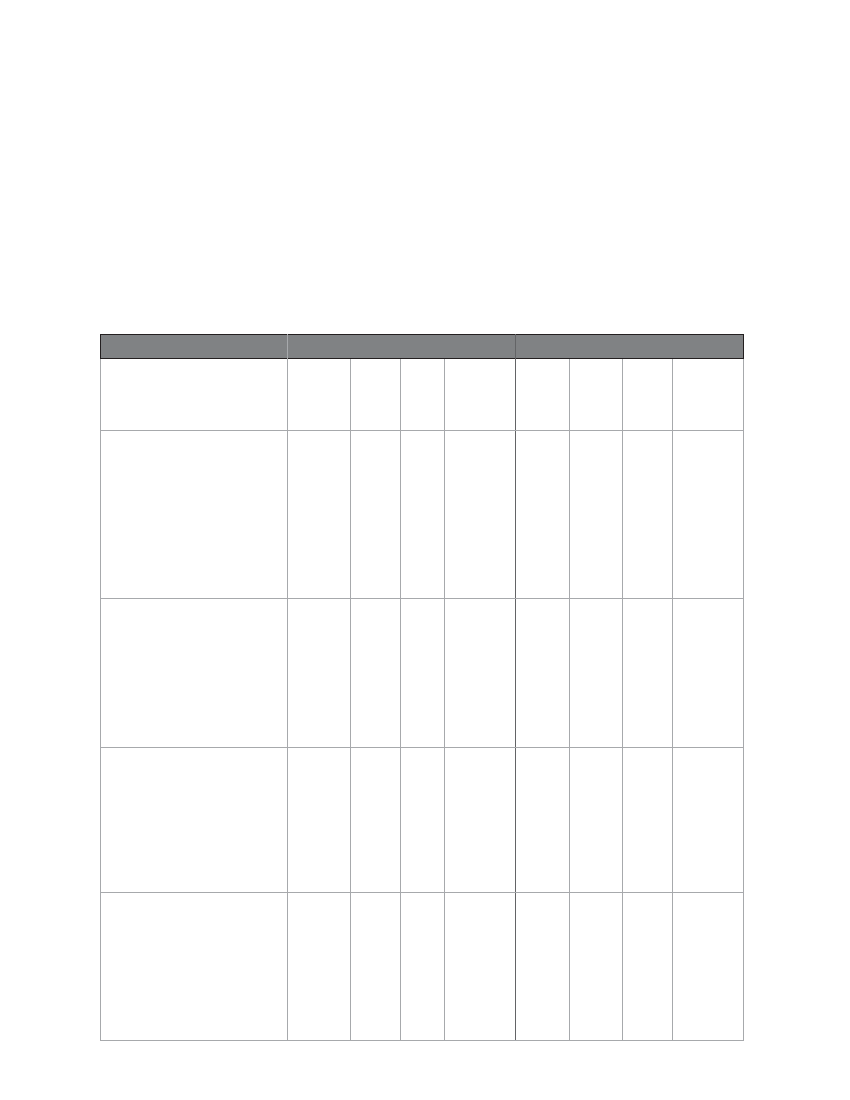

TABLE 7.1 Support pier spacing (centre to centre horizontal length in metres)

EFFECTIVE PIPE WALL

PLAIN PIPE

PIPE WITH WEAR PLATES

THICKNESS, T

(mm):

effective

320 N/mm2 STEEL

1.3 1.9 2.6 3.9

1.3 1.9 2.6 3.9

410 N/mm2 STEEL

1.0 1.5 2.0 3.0

1.0 1.5 2.0 3.0

(a) Total head

htotal< 100 m

100 mm dia

2.0 3.2 4.0 4.7

2.0 3.2 4.0 4.7

200 mm dia

4.1 6.0 7.3 8.3

4.1 6.0 7.3 8.3

300 mm dia

2.5 5.7 8.6 10.5

4.9 7.0 8.6 10.5

400 mm dia

1.4 2.6 5.8 11.7

5.1 7.4 9.1 11.7

500 mm dia

- 2.1 3.7 8.7

4.1 7.5 9.3 12.0

(b) 100 <h < 150 m

total

100 mm dia

1.9 3.1 4.0 4.7

1.9 3.1 4.0 4.7

200 mm dia

3.9 5.8 7.1 8.3

3.9 5.8 7.1 8.3

300 mm dia

2.5 5.7 8.2 10.5

4.4 6.7 8.2 10.5

400 mm dia

1.4 2.6 5.8 11.2

4.4 6.9 8.6 11.2

500 mm dia

- 2.1 3.7 8.7

4.0 6.8 8.7 11.5

(c) 150 < h < 200 m

total

100 mm dia

2.3 3.5 4.7

2.3 3.5 4.7

200 mm dia

2.7 5.0 6.5 8.3

2.7 5.0 6.5 8.3

300 mm dia

2.5 5.7 7.6 10.1

3.2 5.8 7.6 10.1

400 mm dia

1.4 2.6 5.8 10.6

3.0 6.0 7.9 10.6

500 mm dia

_ 2.1 3.7 8.7

2.0 5.8 7.9 10.7

(d) 200 <htotal< 250 m

100 mm dia

_ 1.8 3.1 4.7

1.8 3.1 4.7

200 mm dia

1.8 4.4 6.0 8.3

1.8 4.4 6.0 8.3

300 mm dia

2.1 5.2

7.0 9.7

2.1 5.2 7.0 9.7

400 mm dia

2.6 5.8 10.1

- 5.1 7.2 10.1

500 mm dia

_ 2.1 3.7 8.7

- 4.7 7.1 10.1