CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

57

that debris cannot get in and block the pipe.

As far as possible, the pipe alignment should be such

that it is always sloping downhill. This ensures that

there is always a positive head over the pipe and the

chance of it being blocked is also reduced.

If there is a need for inverted siphons (or the pipe

needs to go uphill for some length due to the ground

profile), air release valves should be provided at high

points along the alignment. Similarly, flush valves

should also be provided at low points to flush sediment

from the pipes and hence prevent them from being

clogged.

Note that the setting out and preparation of the bench

for headrace pipe is similar to the headrace canal

discussed in Section 4.4. As mentioned earlier, HDPE

pipes should always be buried. A minimum buried depth

of 1 m with sieved soil 150 mm to 300 mm around the

pipe is recommended as shown in Figure 4.8. The use

of sieved soil ensures that the pipe is not punctured by

pointed rocks during compaction, distributes the loads

evenly and prevents future differential settlements

above the pipe. The 1 m depth minimises the

overburden loads over the pipe such as when people or

cattle walk over it. Also, in areas where freezing is

expected during mid-winter, 1 m is usually sufficient

to be below the frost line.

At inlet and outlet sections of a headrace pipe, it is

recommended to provide inlet and outlet structures of

stone masonry or concrete.

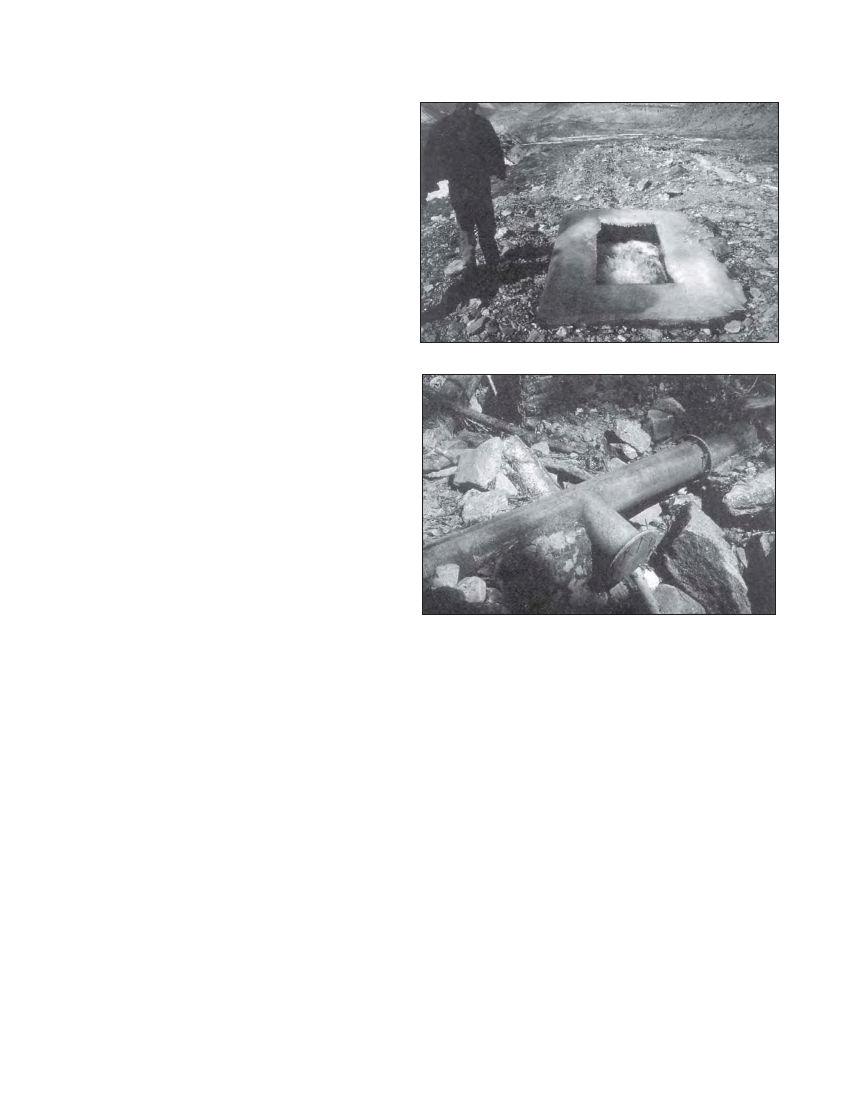

Photo 4.16 Break-pressure tank, with ice around the walls (Jhong)

Photo 4.17 Flush-outs should be provided at low points in pipelines so that

heavy debris can be periodically removed (Siklis)