CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

49

n is the roughness coefficient of the canal (also called

Manning's n) which is dependent on the materials of the

canal. The value of n for different types of canal is given in

Table 4.1.

A is the cross sectional area up to the water surface level

inm2.

S is the slope of the energy grade line. The invert slope of the

canal is used for S since it is parallel to the energy grade

line at longer lengths. For example 1:500 (1 in 500) invert

slope is 1 m of drop in level in 500 m of horizontal canal

length.

Sometimes percentage (%) or fractions are also used to denote

the slopes. For example a slope of 1% means that there will be

a difference in level of 1 m every 100 m of horizontal distance.

The equivalents of the slope in fractions or decimals are given

by the following examples;

2% = 2/100 = 0.02 = 1 in 50

2 in 1000 = 2/1000 = 0.002 = 1 in 500

1.5% = 1.5/100 = 0.015 = 1 in 67

3.5 in 1000 = 3.5/1000 = 0.0035 = 1 in 286

R is the hydraulic radius. R = A/P

P is the wetted perimeter in m. This is the total length of the

bottom and the two sides of the canal up to the

water surface level.

4.3.3 SEDIMENT DEPOSITION IN CANALS

The velocity in each section of the headrace canal should be

high enough to transport any sediment entering that section.

Between the intake and the gravel trap a velocity of 1.5 - 2.0

m/s is recommended. Between the gravel trap and the settling

basin a lesser velocity is possible, but the sediment transport

capability should be checked using a simplified version of

Shield’s formula: d=11RS

where:

d is the size of particle transported in a canal, in m

R is the hydraulic radius, in m

S is the canal bed slope.

If the gravel trap is designed to settle particles larger than 2

mm, then the canal downstream of the gravel trap must be

able to transport particles up to 2 mm.

Research at Wageningen University in the Netherlands

demonstrated that the roughness is increased for channels

under 1 metre in depth, because of the turbulence created by

the side and bed surfaces. The research showed that the

following equations can be used to find the roughness

coefficient. H is the depth of water.

Well maintained channels with little vegetation:

n = 0.03/ H

H<1m

Channels with short vegetation:

n = 0.04/ H

H<1m

Heavily overgrown channels:

n = 0.08/ H

H<1m

In practice it is sensible to maintain short vegetation in order

to protect the banks of canals.

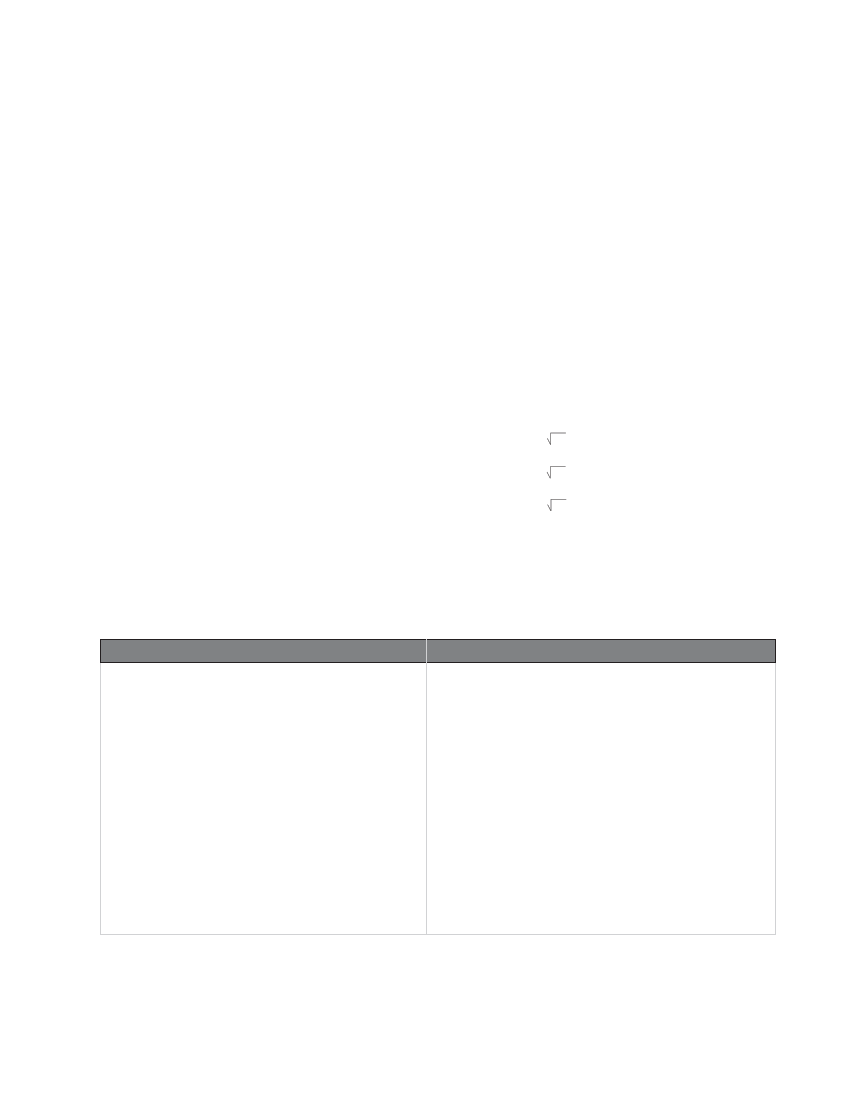

TABLE 4.2 Recommended side slopes for headrace canals

CANAL MATERIAL

SIDE SLOPE ( N = hfv )

Rock/conglomerate (hard to loose)

0 (vertical) to 0.5

Firm clay

0.25 to 0.5

Loam

1.0 to 1.5

Sandy clay, sandy loam

1.5 to 2.0

Silty sand, sandy earth

2.0 to 2.5

Loose sandy earth, porous earth

2.5 to 3

Gravely earth, stiff or loose conglomerate

0.5 to 1

Gravel and boulder mixed with earth (soft and loose)

1.5 to 2

Stone masonry in mud mortar

See Note 2

Stone masonry in cement mortar

See Note 2

Plain concrete

See Note 2

Note :

1 These values are for canals excavated in soil of low moisture content with water table below canal bed. Slopes need to be

flattened if these conditions are not achieved.

2 The sides of lined canals may be vertical (designed as retaining walls) or at the slope recommended for the underlying soil.