The best indication of a successful biogas plant is a significant reduction in the average amount of

time worked - especially by women and children who tend the plant and cook with the gas. If, for

example, the family used to cook on wood gathered on the way back from the fields, a practice that

involved little extra work, biogas technology can hardly expect to find acceptance under the heading

"time saved".

The actual value of time saved depends not only on the quantity saved but also on the quality, i.e.

whose workload is reduced at which time of day.

Real-time savings let the target group:

- expand their cash-crop and/or subsistence production

- intensify and improve their animal-husbandry practice

- expand their leisure time and have more time for their children, education, etc.

It should be noted that all time expenditures and time savings pertaining to anyone participating in

the farm/household work, and which can be expressed in real monetary terms as cash-flow income

or expenses must appear both in the above working-time balance and in the following micro-

economic analysis (wage labor during the time saved by the biogas plant).

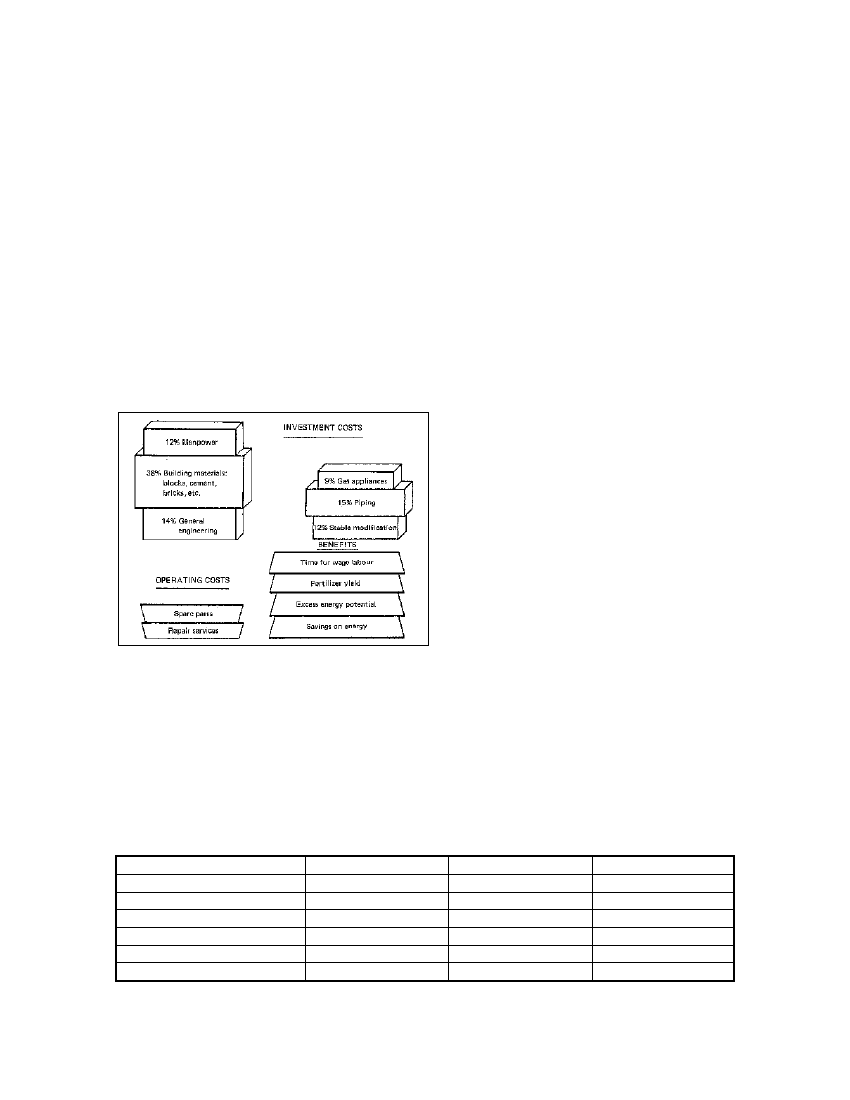

Fig. 8.2: Costs and benefits of a fixed-dome

biogas plant (Source: OEKOTOP)

8.3 Micro-economic analysis for the user

The following observations regarding micro-economic analysis (static and dynamic) extensively

follow the methods and calculating procedures described in the pertinent publication by H. Finck

and G. Oelert, a much-used reference work at Deutsche Gesellschaft fur Technische

Zusammenarbeit (GTZ) GmbH that should be consulted for details of interest.

Table 8.2: Investment-cost comparison for various biogas plants (Source: OEKOTOP)

Cost factor

Cost per m³ digester (DM)

including:Gasholder

Digester/slurry store

Gas appliances/piping

Stable modification

General engineering

Water-jacket. Plant

200-400

23 %

35%

22%

8%

12%

Fixed-dome plant

150 - 300

(part of digester)

50%

24%

12%

14%

Plastic-sheet plant

80-120

8%

42%

36%

-

14%

97