Ventilation:

Turning the

eggs:

Barren eggs:

A steady supply of fresh air (but not draft) is required to keep the CO2 content

below 0.8 %.

Incubating eggs must be turned as often as 8 times a day to keep the chicks

from sticking to the inside of the shell.

Unfertilized eggs and eggs containing dead chicks must be removed (danger of

infection). The eggs should be candletested once per week to ensure timely

detection.

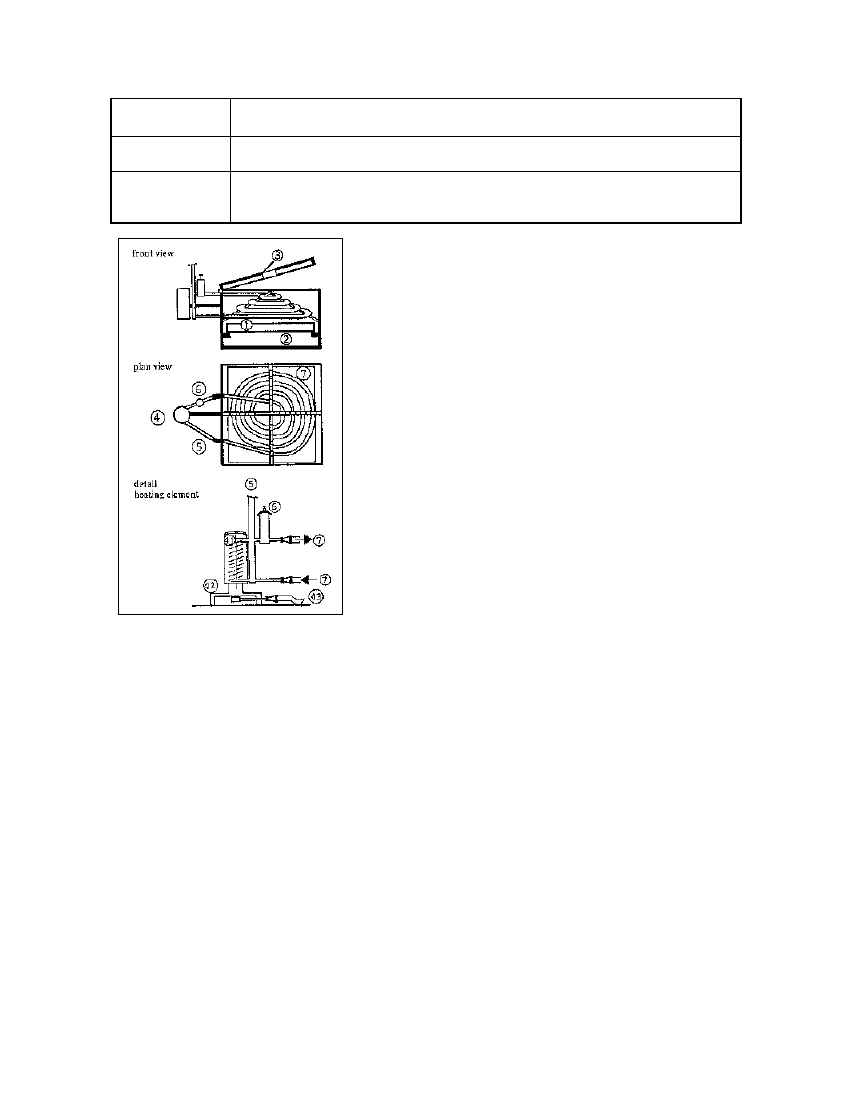

Fig. 5.34: Schematic drawing of an incubator. 1 Incubating

chamber, 2 Removable tray, 3 Cover/ venting lid, 4 Heating

element, 41 Heating coil, 42 Burner, 43 Gas pipe, 5 Water

filler neck and expansion tank, 6 Vent valve, 7 Warming

element (plastic hose). Biogas consumption rate: 30-50 1/h

(Source: Wesenberg 1985)

Incubators

Incubators are supposed to imitate and maintain optimal conditions for hatching eggs. They are

used to increase brooding efficiency. Indirectly warm-water-heated planar-type incubators in which

a biogas burner heats water in a heating element for circulation through the incubating chamber are

suitable for operating on biogas. The temperature is controlled by ether-cell-regulated vents (cf. fig.

5.34).

Refrigerators

Absorption-type refrigerating machines operating on ammonia and water and equipped for

automatic thermosiphon circulation can be fueled with biogas.

Since biogas is only the refrigerator's external source of heat, just the burner itself has to be

modified. Whenever a refrigerator is converted for operating on biogas, care must be taken to

ensure that all safety features (safety pilot) function properly; remote ignition via a piezoelectric

element substantially increases the ease of operation.

73