- Plants of a size exceeding 100 m³ usually cannot be made of masonry, i.e. the types of plant

discussed in chapter 5 cannot be used.

The choice of plant is limited to either the mechanized types used in industrial countries or simple,

large-scale plants. Experience shows that most simple, large-scale plants are

- of modular design,

- usually equipped with channel digesters,

- and require the use of substrate from which the scum-forming material has been removed in

order to get by with either low-power mechanical mixers or none at all.

Since large-scale biogas plants produce accordingly large volumes of biogas, the generation of

electricity with the aid of a motor-generator set is of main interest.

The two Ferkessedougou biogas plants situated in the northern part of Cote d' Ivoire stand as

examples of a successful large-scale biogas-plant concept based on a simple design. They have

been in operation at the local cattle-fattening station and slaughterhouse since 1982 and 1986,

respectively, where they serve in the disposal of some of the excrements produced by an average

number of 2500 head of cattle. The plant consists of a simple, unlined earth-pit digester with a

plastic-sheet cover serving as gasholder. The gas is used for generating electricity, heating water

and producing steam.

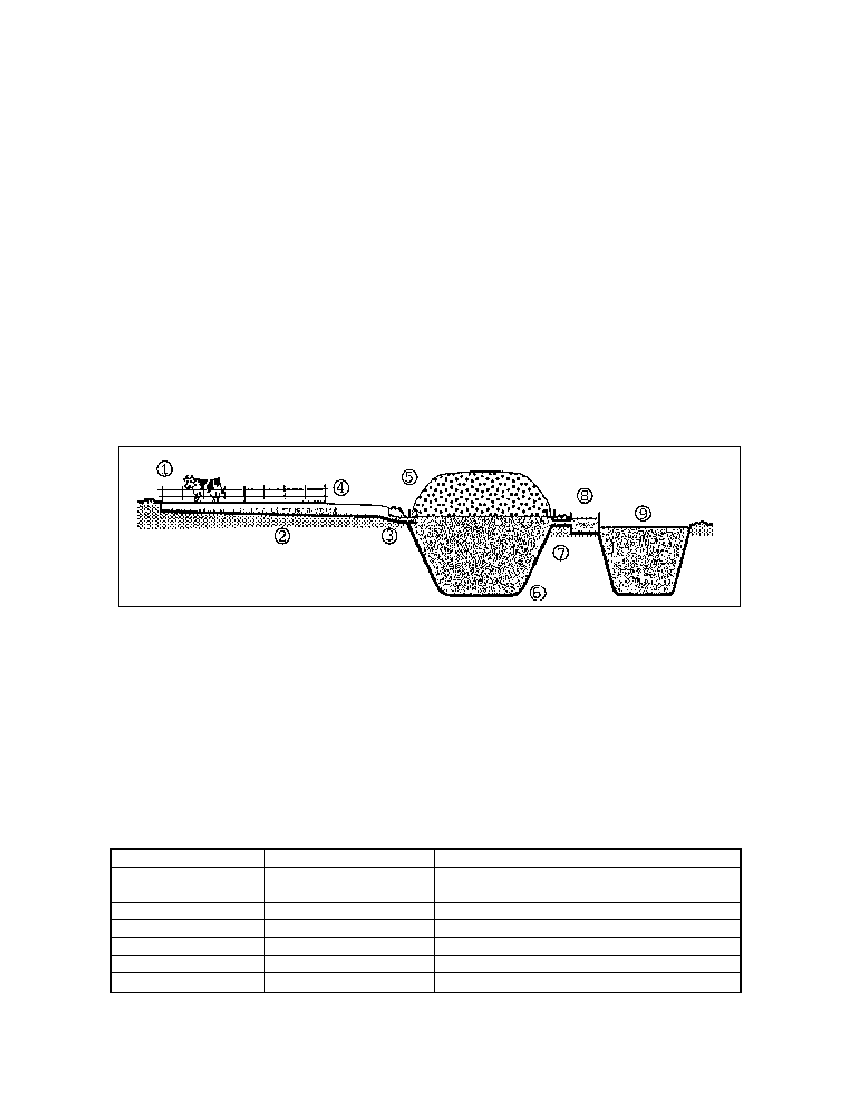

Fig. 6.2: Biogas plant in Ferkessedougou - system OEKOTOP. 1 Cattle feedlot, 2 Manure gutter, 3

Feedpipe, 4 Sluice, 5 Rubber-sheet gasholder, 6 Earth-pit digester, 7 Discharge pipe, 8 Impounding

weir, 9 Slurry storage (Source: OEKOTOP)

At present, some 20% of the slaughterhouse's electricity requirement is covered by the biogas

plants, and the biogas-driven steam sterilizer saves 50 000 I diesel fuel each year. The total initial

investment amounting to 60 million F.CFA yields annual savings of approximately 12 million F.CFA

after deduction of the operating costs (1 DM = 150 F.CFA).

The Ferkessedougou biogas plants demonstrate how even large-scale installations can keep

biogas technology cost-efficient by relying on simple designs, e.g. large digester volume despite low

cost of construction.

Table 6.2: Technical data of the Ferkessedougou biogas plant (Source: OEKOTOP)

No. of animals

Digester volume

Gasholder volume

Slurry storage volume

Retention time

Daily substrate input1

Biogas plant I

700 head of cattle in 12

feedlots

400 m³

80 m³

300 m³

40-2s days

10-18 m³/d

Biogas plant II

810 m³

>600 m³

3500 m³

40 -22 days

20-38 m³/d

85