1. An introduction to biogas technology

Biogas technology

. . . is a modern, ecology-oriented form of appropriate technology based on the decomposition of

organic materials by putrefactive bacteria at suitable, stable temperatures. A combustible mixture of

methane and carbon dioxide, commonly referred to as biogas, develops under air exclusion (leaving

behind digested slurry) in the digester - the heart of - any biogas plant.

To ensure continuous gas production, the biogas plant must be fed daily with an ample supply of

substrate, preferably in liquid and chopped or crushed form. The slurry is fed into the digester by

way of the mixing pit. If possible, the mixing pit should be directly connected to the livestock housing

by a manure gutter. Suitable substrates include:

- dung from cattle, pigs, chickens, etc.,

- green plants and plant waste,

- agroindustrial waste and wastewater.

Wood and ligneous substances are unsuitable.

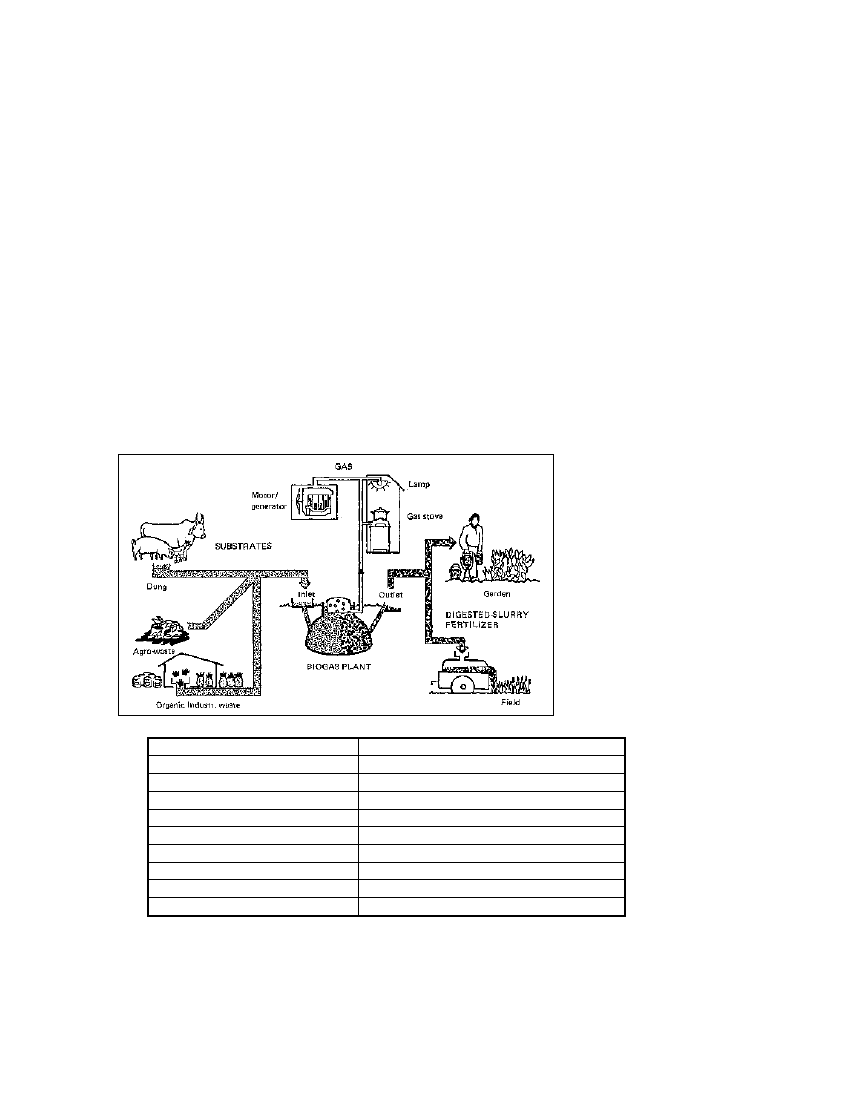

Fig. 1.1: A typical biogas-

system

configuration

(Source: OEKOTOP)

Biogas guideline data

Suitable digesting temperature:

Retention time:

Biogas energy content:

Biogas generation:

1 cow yields:

1 pig yields:

Gas requirement for cooking:

for 1 lamp:

for engines:

20 - 35 °C

40 - 100 days

6 kWh/m³ = 0.61 diesel fuel

0.3-0.5 m³ gas/m³ digester volume x day

9-15 kg dung/day = 0.4m³ gas/day

2-3 kg dung/day = 0.15 m³ gas/day

0.1-0.3 m³ /person

0.1-0.15 m³ /h

0.6 m³/kWh

A simple 8 - 10 m³ biogas plant produces 1.5-2 m³ and 1001 digested-slurry fertilizer per day on

dung from 3-5 head of cattle or 8 - 12 pigs. With that much biogas, a 6 - 8 person family can:

4