Table 5.15: Pointers on flame adjustment (Source: OEKOTOP)

Problem

elongated, yellow- ish flame

flame "lifts off"

flame "flashes back"

flame "too small"; not enough fuel

flame "too big"; excessive fuel

supply/consumption

Cause - Remedy

lack of combustion air - open the air supply

excessive exit velocity - use smaller injector, reduce the

gas pressure, reduce the air supply

exit velocity too low - use larger injector, increase the gas

pressure, open the air supply, reduce the size of the

burner jets

fuel shortage - use larger injector, increase the gas

pressure

excessive fuel supply - reduce the gas pressure, use

smaller injector

5.5.3 Biogas appliances

Biogas is a lean gas that can, in principle, be used like any other fuel gas for household and

industrial purposes, the main prerequisite being the availability of specially designed biogas burners

or modified consumer appliances. The relatively large differences in gas quality from different

plants, and even from one and the same plant (gas pressure, temperature, calorific value, etc.)

must be given due consideration.

The heart of any gas appliance is the burner. In most cases, atmospheric-type burners operating on

premixed air/gas fuel are considered preferable.

Due to complex conditions of flow and reaction kinetics, gas burners defy precise calculation, so

that the final design and adjustments must be arrived at experimentally.

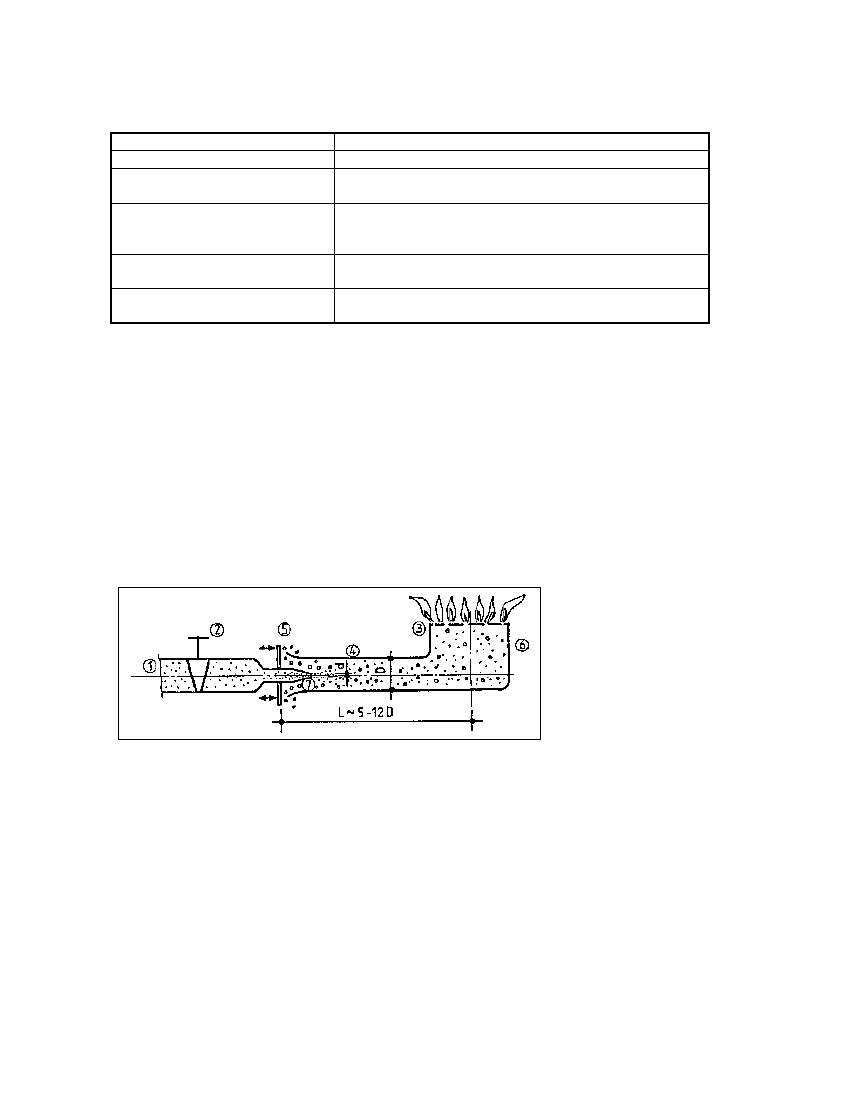

Fig. 5.30: Schematic

drawing of a biogas burner

and its parts. 1 Gas pipe, 2

Gas-flow shutoff/reducing

valve, 3 Jets (f = 1-2 mm), 4

Mixing chamber for gas and combustion air, 5 Combustion air intake control, 6 Burner head, 7

Injector (Source: Sasse 1984)

Accordingly, the modification and adaptation of commercial-type burners is an experimental matter.

With regard to butane and propane burners, i.e. the most readily available types, the following

pointers are offered:

- Butane/propane gas has up to 3 times the calorific value of biogas and almost twice its

flame-propagation rate.

- Conversion to biogas always results in lower performance values.

- Practical modification measures include:

- expanding the injector cross section by a factor of 2-4 in order to increase the flow of gas

67