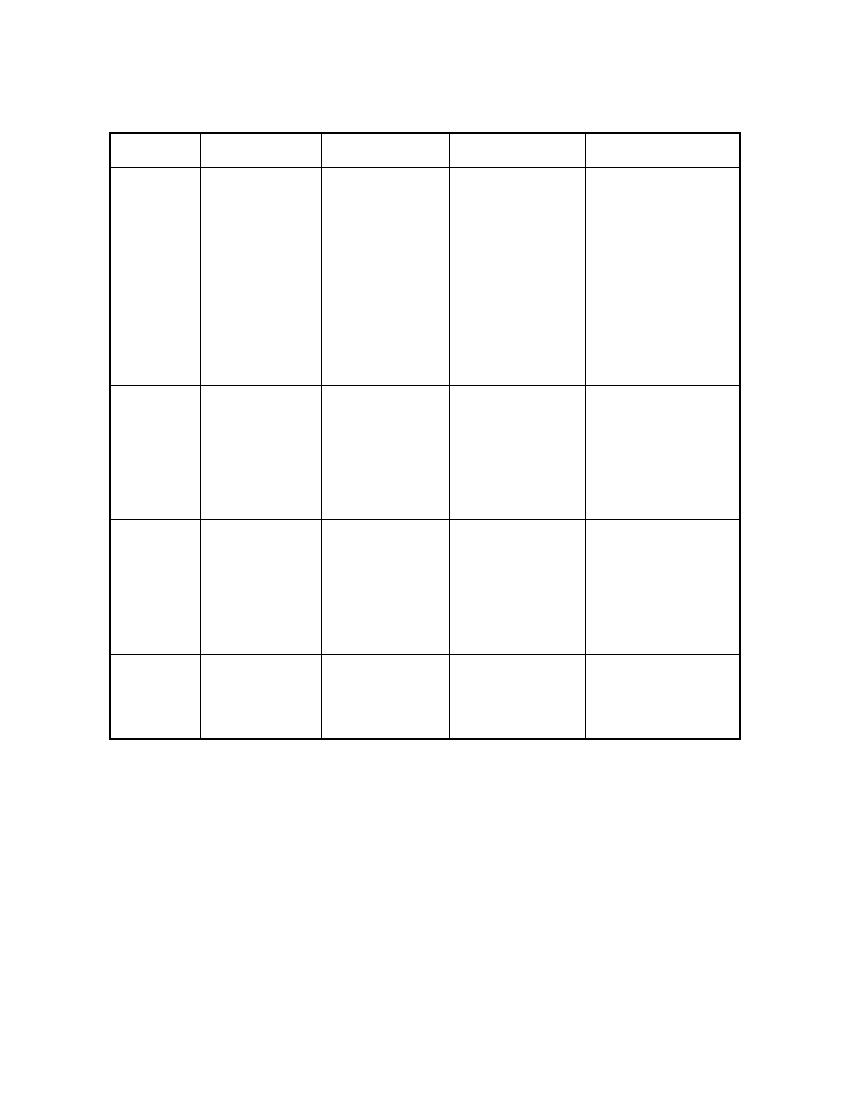

Table 9.5: Target-group-oriented biogas training measures (Source: OEKOTOP)

Target

group

Engineers,

local

extension

officers

Artisans

Users

Women

Training

elements

Seminars and field

trips, national

workshops, supra-

regional

conferences

serving to effect

technology

transfer

Integrated

workshops with

theoretical +

practical training,

incl. On- the-job

training (OJT)

Field trips to

operable plants,

participation in

workshops On-the-

spot training (own

plant)

On-the-spot

training (own

plant), local

evening courses

Contents

Function of various

types of biogas

plants and

peripheral

equipment, use of

digested slurry,

maintenance and

repair problems,

macro- and

microeconomic

analysis/evaluation,

project

management

Function of selected

types of plants,

design and

construction per

drawing, use of

local materials,

maintenance &

repair

Function of selected

types of plants,

operation and

optimal use,

fertilizing with

digested slurry,

maintenance &

repair

Plant function,

operation and

optimal use,

working with biogas

cookers

Duration

several blocks of

approx. 1 week each

workshops lasting

several days,

participation in plant

construction

2-3 days, regular on-

site back- stopping

continuous

familiarization

(women!)

Instructor

biogas experts,

agricultural experts,

social economists

engineers, experienced

artisans

local biogas/ agricultural

extension workers

local biogas extension

workers

9.6 Financing

Small farmers in particular rarely have the DM 1000 - 2500 or more it takes to cover the cost of a

biogas plant. Consequently, "mixed-financing models" with the three elements own

capital/contribution, subsidy and loan must be available.

Own capital/contribution

While a potential user may not be able to fully finance a biogas plant by himself, he must be

expected to carry at least 30 - 40% of the initial outlay, possibly in the form of contributed work like

digester excavation, procuring building materials, etc.

110