When installing a gas pipe, special attention must be paid to:

- gastight, friction-type joints

- line drainage, i.e. with a water trap at the lowest point of the sloping pipe in order to rule out

water pockets

- protection against mechanical impact.

Some 60% of all system outages are attributable to defective gas pipes. For the sake of

standardization, it is advisable to select a single size for all pipes, valves and fittings.

Valves and fittings

To the extent possible, ball valves or cock valves suitable for gas installations should be used as

shutoff and isolating elements. Gate valves of the type normally used for water pipes are

conditionally suitable. Any water valves used must first be checked for gastightness.

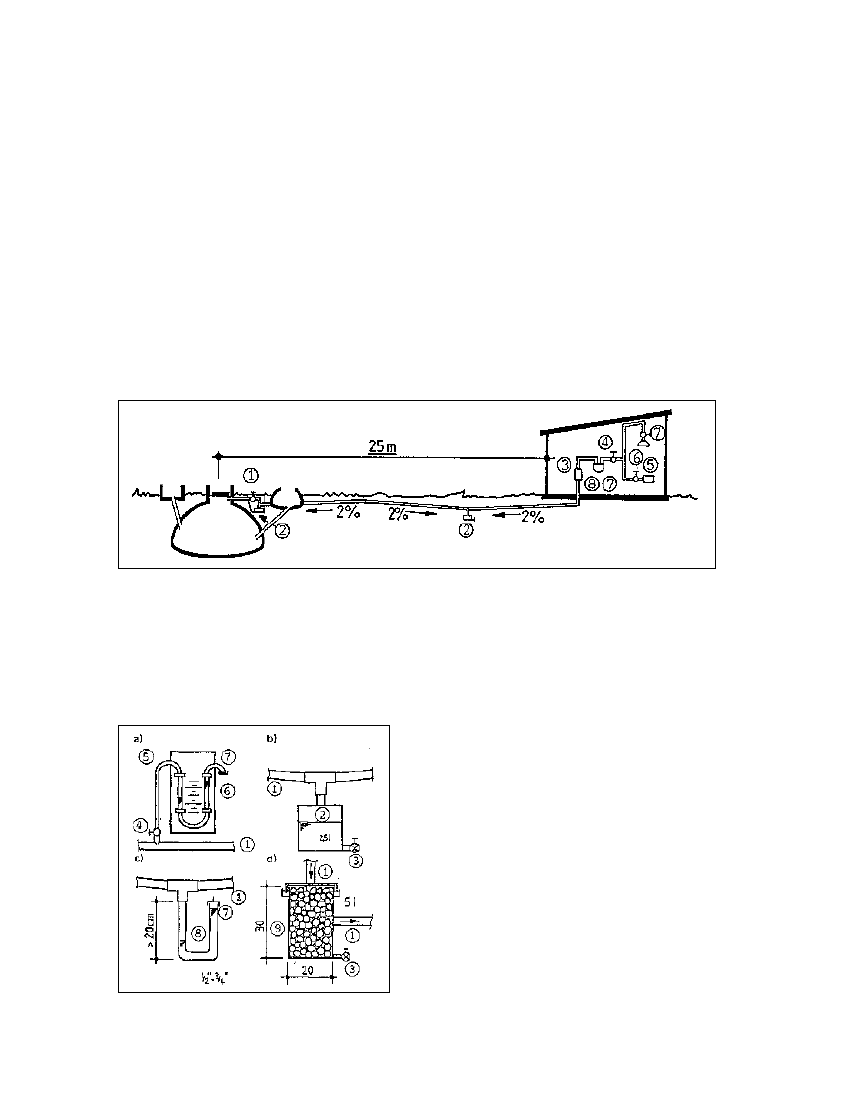

Fig. 5.27: Gas pipe, valves and fittings of a biogas plant. 1 Plant shutoff valve, 2 Water trap, 3

Pressure gauge, 4 House shutoff valve, 5 Cookstove, 6 Lamp, 7 Appliance shutoff valve, 8

Gasmeter (Source: OEKOTOP)

Gas manometer

A U-tube pressure gauge is quick and easy to make and can normally be expected to meet the

requirements also of a fixed-dome system.

Fig. 5.28: Gas valves and fittings: U-tube pressure

gauge (a), water trap with drain valve (b), U-tube

water separator (c), "gravel-pot" flashback arrestor

(d). 1 Gas pipe, 2 Condensate collector, 3 Shutoff

valve, 4 Manometer valve, 5 U-tube pressure gauge

made of transparent hose, 6 Wooden balls, 7

Antievaporation cap, 8 U-tube, 9 "Gravel-pot"

flashback arrestor (approx. 51) filled with 20 mm

gravel (Source: OEKOTOP)

64