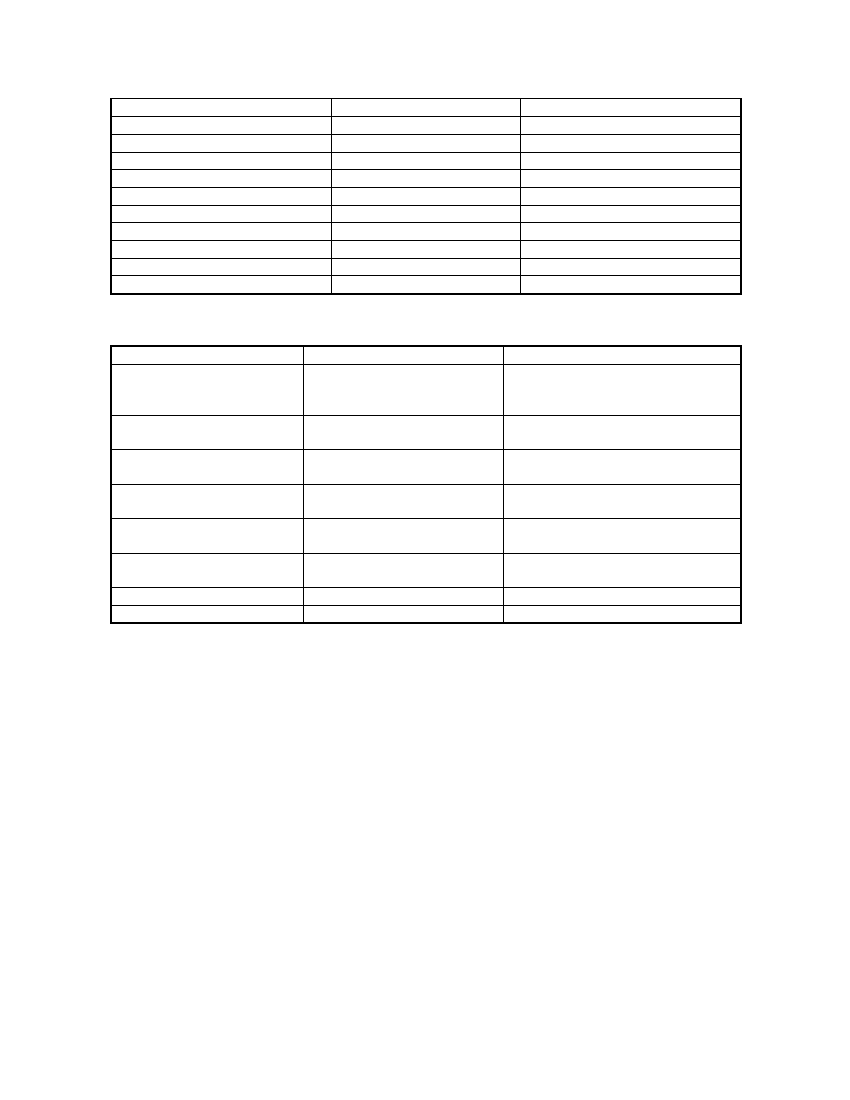

Stuck gas cocks

Leaky gas pipe

Sudden loss of gas

Pulsating gas pressure

Malfunctioning gas appliances

Structural damage

corrosion

corrosion, inferior workman-

ship

- broken gas line

- blown-off water trap

- open gas cock

water in the gas pipe

plugged-up gas pipe

cf. chapter 5.5.3

cf. table 7.1

apply oil, ,operate repeatedly

repair

repair

refill with water

close

pump out the pipe, relocate that

section of pipe

push rod through pipe

cf. chapter 5.5.3

cf. table 7.1

Table 7.5: Potential repair situations for simple biogas plants (Source: OEKOTOP)

Damage

Damaged masonry and

rendering

Damaged or broken

inlet/outlet pipe

Damaged/leaky fixed-dome

plants

Damaged/corroded

gasholder

Broken guide frame

Leaky/broken/corroded gas

pipe

Damaged valves/fittings

Damaged gas appliances

Detection

Inspection of open plant,

subsiding slurry level,

(see above)

Gas seal test, visual

inspection of open plant

High gas losses, seal test

Remedial measures

Inspect the plant and repair any

seal test damage; tear down the

plant if large cracks are found

Replace pipe, repair connection to

masonry

Repair rendering, renew seal

coatings

Replace gasholder, renew weldings

Tilted/immobile gasholder

High gas losses, gas seal test

of pipe

Functional inspection

Functional inspection

Remove gasholder, repair guide

frame

Locate damage, repair or replace

as necessary

as a rule: replace

cf. "Gas appliances"

7.5 Safety measures

Biogas is a combustible, explosive gas. Its safe handling and use can be ensured, or at least

promoted, by:

- educational measures and operating instructions

- good, careful planning and execution

- timely detection of damage and gas leaks

- installation of safety equipment

Safety aspects of planning and implementation

The following basic rules should be adhered to:

- plant located outside of buildings used for other purposes, e.g. stablings

- underground installation of pipes

- no use of hoses

- careful installation and regular inspection of gas pipes

- regular inspection of gas appliances

- good ventilation of rooms containing gas appliances without safety pilots

- installation of safety stop valves

- one directly on the plant, and another on each appliance.

94