Earth-pit plants (cf. fig. 5.13)

Masonry digesters are not necessary in stable soil (e.g. Iaterite). It is sufficient to line the pit with a

thin layer of cement (netting wire fixed to the pit wall and rendered) in order to prevent seepage.

The edge of the pit is reinforced with a ring of masonry that also serves as anchorage for the

gasholder. The gasholder can be made of metal or plastic sheeting. If plastic sheeting is used, it

must be attached to a quadratic wooden frame that extends down into the slurry and is anchored in

place to counter its buoyancy. The requisite gas pressure is achieved by placing weights on the

gasholder. An overflow point in the peripheral wall serves as the slurry outlet.

Advantages: Low cost of installation (as little as 1/5th as much as a floating-drum plant), including

high potential for self help.

Drawbacks: Short useful life, serviceable only in suitable, impermeable types of soil.

Earth-pit plants can only be recommended for installation in impermeable soil located above the

groundwater table. Their construction is particularly inexpensive in connection with plastic sheet

gasholders.

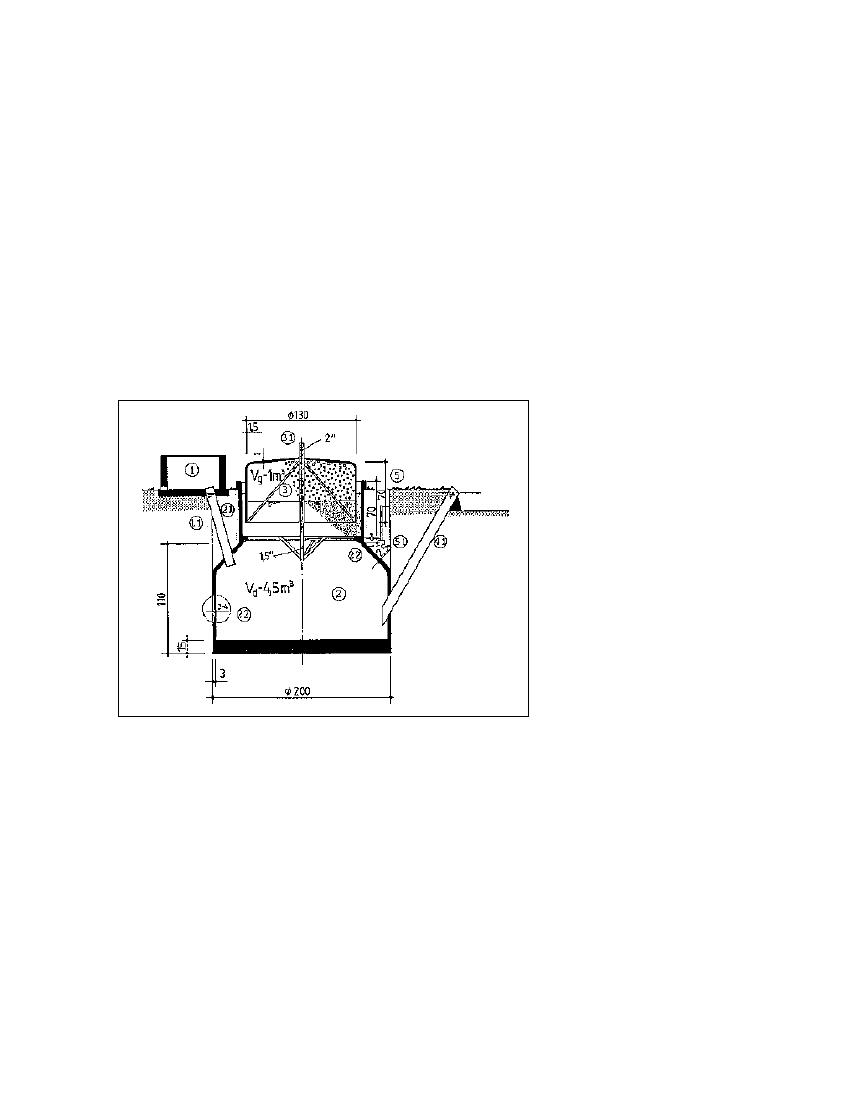

Fig 5.14: Ferrocement biogas

plant. 1 Mixing pit, 11 Fill pipe,

2 Digester, 21 Backfill soil, 22

Ferrocement, i.e. rendered

lathing on surrounding soil, 3

Ferrocement gasholder, 31

Guide frame, 41 Outlet pipe, 5

Cas pipe, 51 Water trap

(Source:

OEKOTOP/BEP

Caribbean 1986)

Ferrocement plants (cf. fig. 5.14)

The ferrocement type of construction can be executed as either a self-supporting shell or an earth-

pit lining. The vessel is usually cylindrical. Very small plants (Vd <6 m³) can be prefabricated. As in

the case of a fixed-dome plant, the ferrocement gasholder requires special sealing measures

(provenly reliable: cemented-on aluminium foil).

Advantages: Low cost of construction, especially in comparison with potentially high cost of

masonry for alternative plants.

Drawbacks: Substantial consumption of necessarily good-quality cement; participating craftsmen

must meet high standards; uses substantial amounts of steel; construction technique not yet

adequately timetested; special sealing measures for the gasholder.

Ferrocement biogas plants are only recommended in cases where special ferrocement know-how is

available.

50