Digester loading:

Ld = TS/VS-input: Vd

Ld = 18: 18 = 1.0 kgTS/m³ Vd

Ld = 12: 18 = 0.7 kg VS/m³ Vd

Gasholder volume:

Vg = 1.6 m³, as calculated on the basis of:

consumption volume:

Vg1 = 0.175 m³/h x 2 flames x 3 h = 1.05 m3

Storage volume:

Vg2 = 10 h x 0.15 m³ gas/h = 1.5 m³

Vd:Vg=18: 1.6=11 :1

5. Biogas technique

The design aspects dealt with below concentrate solely on the principles of construction and

examples of simple biogas plants, i.e. plants:

- for small family farms requiring digester volumes of between 5 m³ and 30 m³,

- with no heating or temperature control,

- with no motor-driven agitators or slurry handling equipment,

- with simple process control,

- built with (at least mostly) local materials,

- built by local craftsmen.

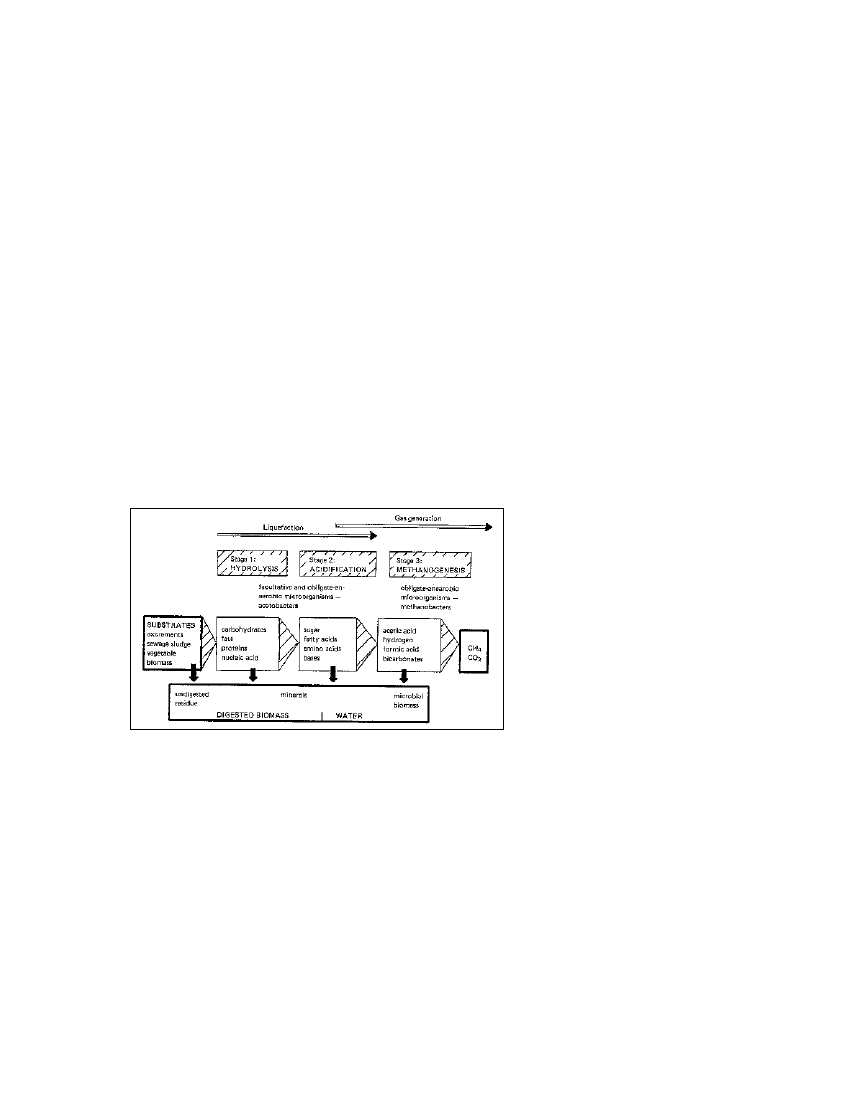

Fig. 5.1: Three-stage anaerobic

fermentation (Source: Baader et.

al 1978)

5.1 Fundamental principles, parameters, terms

Biochemical principles

The generation of biogas by organic conversion (anaerobic fermentation) is a natural biological

process that occurs in swamps, in fermenting biomass and in intestinal tracts, particularly those of

ruminants.

The symbiotic relationships existing between a wide variety of microorganisms leads, under air

exclusion, to the degradation and mineralization of complex biomass in a sequence of intermeshing

stages. The resultant biogas, consisting primarily of methane (CH4) and carbon dioxide (CO2) and

the mineralized slurry constitute the ultimate catabolites of the participating bacteria and residual

substances.

39