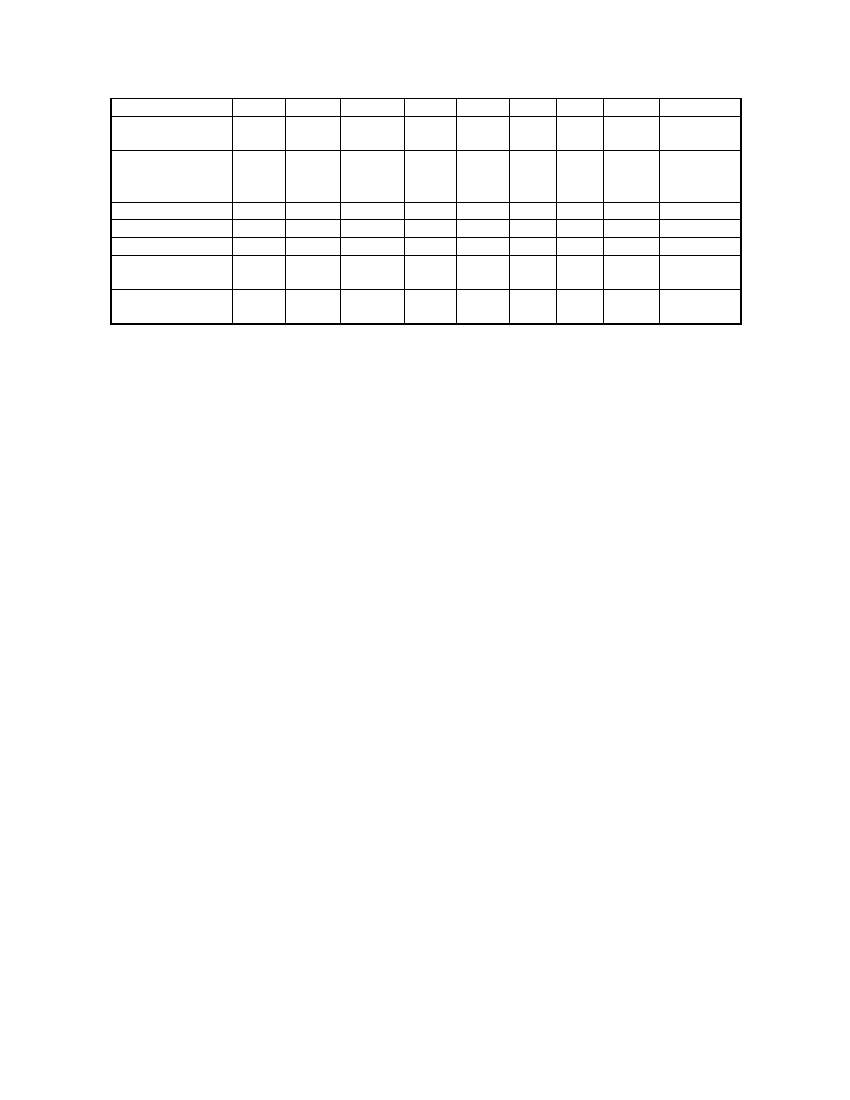

Overnight stabling

- dung only (10%

losses)

- dung and

urine,concrete

floor

1 kg/d moist dung

1 l/d manure

1 kg/d manure

1 kg TS/d

5-8

11-16

~200

180-

270

220-

320

~35

~20

~22

~240

1 kg VS/d

~250 ~300

220-310

260-380

8-10

16-20

240-

300

260-

330

~40 ~34

~25 ~20

~27 ~22

~200 ~240

~250 ~300

2290-

360

330-

410

-

-

-

-

~40 -

~24 ~50

~26 -

~227 ~340

0

~335 ~430

0

-

-

-

~60

-

Sizing the gasholder

The size of the gasholder, i.e. the gasholder volume (Vg), depends on the relative rates of gas

generation and gas consumption. The gasholder must be designed to:

- cover the peak consumption rate (Vg 1) and

- hold the gas produced during the longest zero-consumption period (Vg 2).

Vg1 = gc, max x tc, max = vc, max

Vg2 = G x tz, max

gc, max = maximum hourly gas consumption (m³/h)

tc, max = time of maximum consumption (h)

vc, max = maximum gas consumption (m³)

G = gas production (m³/h)

tz, max = maximum zero-consumption time (h)

The larger Vg-value (Vgl or Vg2) determines the size of the gasholder. A safety margin of 10-20%

should be added. Practical experience shows that 40-60% of the daily gas production normally has

to be stored. Digester volume vs. gasholder volume. (Vd: Vg) The ratio

Vd : Vg

is a major factor with regard to the basic design of the biogas plant. For a typical agricultural biogas

plant, the Vd/Vg-ratio amounts to somewhere between 3: 1 and 10: 1, with 5: 1 - 6: 1 occurring most

frequently.

4.4 Balancing the gas production and gas demand by iteration

As described in subsection 4.1, the biogas/ energy production (P) must be greater than the energy

demand (D).

P>D

This central requirement of biogas utilization frequently leads to problems, because small farms with

only a few head of livestock usually suffer from a shortage of biomass. In case of a negative

balance, the planner must check both sides - production and demand - against the following criteria:

35