P(E, W) = p • A (kp = (kp/m²) • m²)

Note: The above formulae are simplified and intended only for purposes of rough estimation.

10.2 Gas-law calculations

10.2.1 Calculating the pressure drop in a gas pipe

dp = FL + Ztot

dp = pressure drop (N/m²)

FL = friction losses in the gas pipe (N/m²)

Ztot = sum total of friction losses from valves, fittings, etc. (N/m²)

dp = cp l/D • D/2 v2

+ (cfl D/2 • v2 + . . . + cfn • D/2 • v2)

(approximation formula)

cp = coefficient of pipe friction (-)

l = length of pipe section (m)

D = pipe diameter(m)

g = density of biogas (1.2 kg/m³)

v = velocity of gas in the pipe (m/s)

cf = friction coefficients of valve, fittings, etc.

Q=v•A

Q = gas flow (m³/s)

v = velocity of gas in the pipe (m/s)

A = p r2 = cross-sectional area of pipe

The coefficient of pipe friction (cp = non. dimensional) is a function of:

- the pipe material and internal surface roughness

- pipe diameter

- flow parameter (Reynolds number)

For pipe diameters in the 1/2" . . . 1" range, the coefficients of friction read:

PVC tubes approx. 0.03

steel pipes approx. 0.04

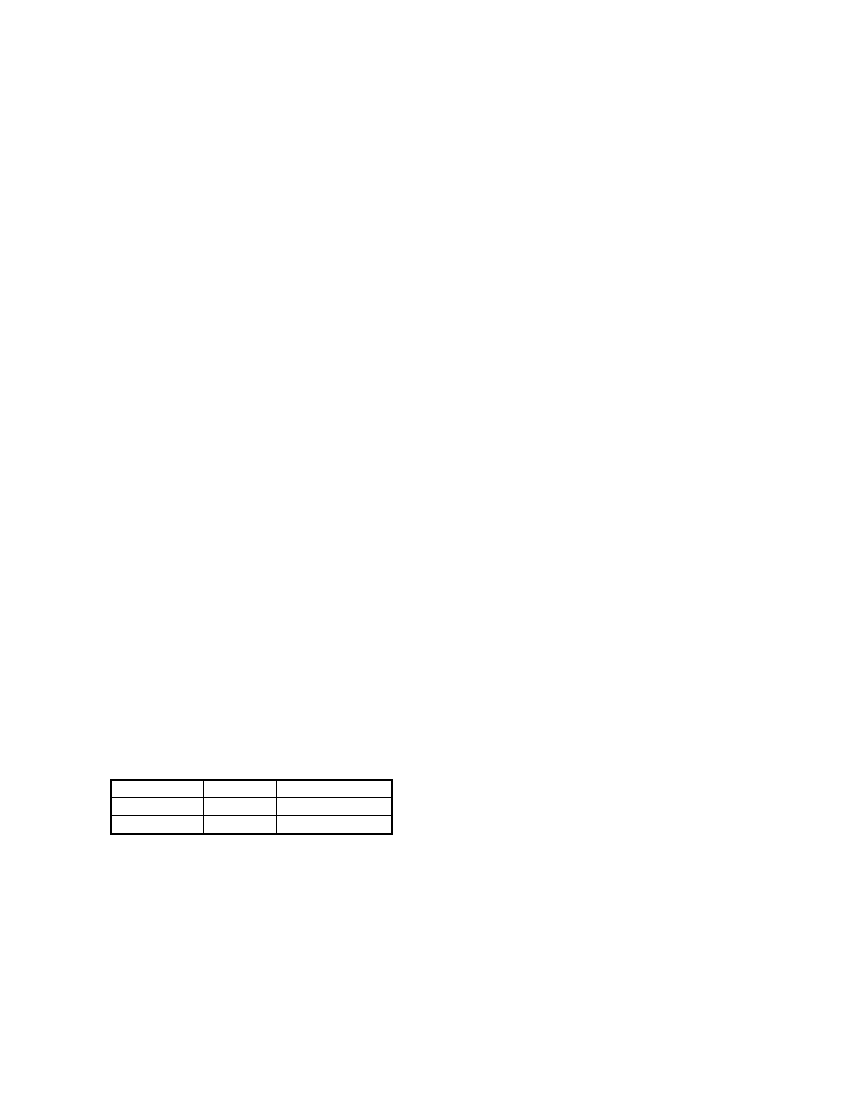

Some individual friction-loss factors (cf; nondimensional)

elbow

constriction

branch

0.5

0.02-0.1

0.8-2.0

valve 3.0

water trap 3 - 5

10.2.2 Calculating gas parameters

Temperature-dependent change of volume and density

D = DN • P • TN / (PN • T)

V = VN • PN • T / (P • TN)

117