Operation and Maintenance

Excessive corrosion

The condition of the rope or its performance

leaves any doubt as to its integrity and

safety in operation

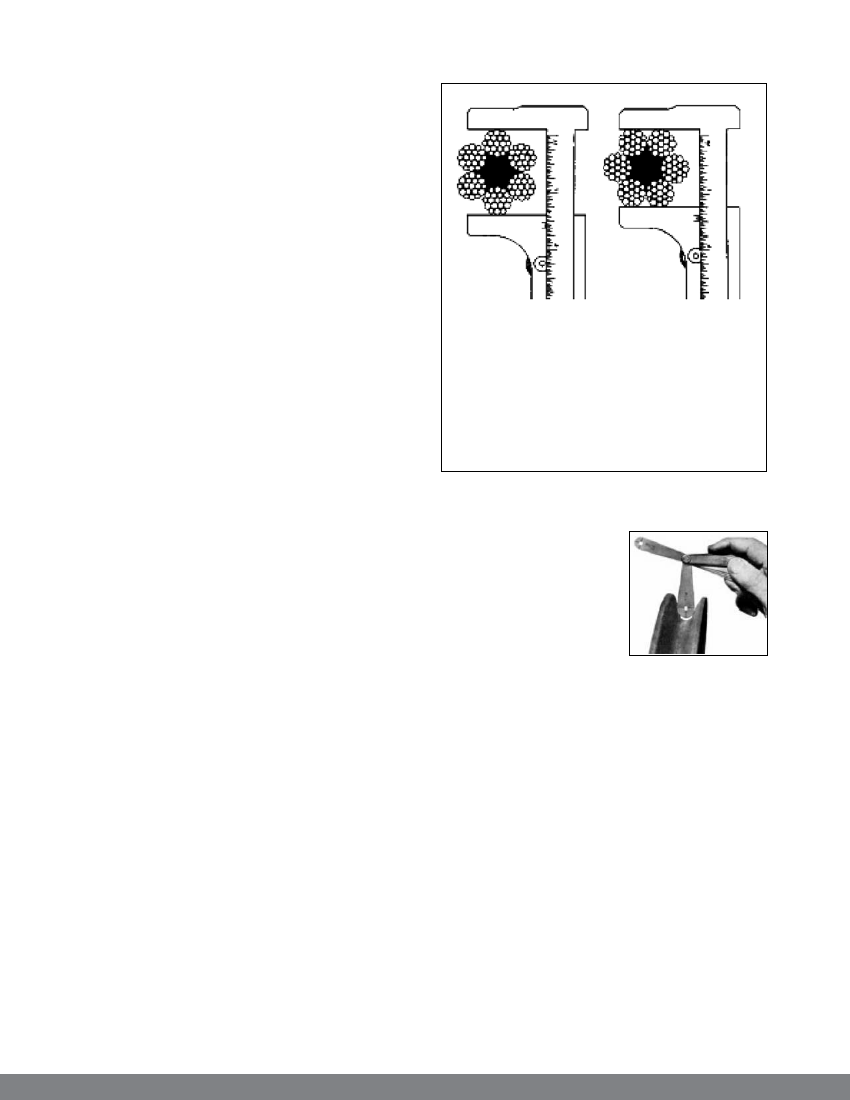

c) Measure the widest diameter

Ropes and sheave grooves must be precisely

fitted to each other to get the maximum service

out of wire ropes. Measurement of rope diameter

is a crucial part of any inspection activity. There

is only one right way to measure rope diameter

- use Vernier's Calipers and make sure that the

widest diameter is measured. These drawings

demonstrate both the right and the wrong way of

measuring the ropes diameter. This method is not

only useful for measuring the diameter of a new

rope, but also for determining the amount of wear

and compression that has occurred while the rope

is in use. Accurate recording of this information is

essential in deciding to replace the wire rope.

d) Lubrication

Wire ropes have a fibre or steel core depending

on the types chosen and are impregnated with oil

which forms an oil film between the strands. There

is a need for periodical lubrication of the rope to

avoid deterioration of the core. The oil reduces

the exposure of ropes to the weather elements

thereby limiting the damage to corrosion. The life

of the rope can be increased by timely application

of lubrication after every 120 to 150 hours of

operation. All the dirt accumulated over the rope

surface, especially the dust, should be cleaned

before the application of grease/lubricant.

Approximately 30 to 40 grams of grease is

required to lubricate each metre length of rope.

Regular maintenance of the rope with proper

lubrication increases the life of the rope by two to

three times. The lubricant/grease heated to 60 to

70 degrees temperature may be used.

9.2.2 Sheaves

a) Sheave inspection

Sheaves should be checked for:

Right Way.

Set the

machinist’s caliper

to read the widest

diameter. Vernier

scale reads to

1/128th of an

inch.

Wrong way.

This is the wrong

wayt measure wire

rope diameter.

Widest diameter

is not being read.

Figure 26: Measurement of rope’s widest diameter

Correct groove

diameter

Roundness or contour

to give proper support

to the rope;

Small holes, cracks, Photo 7

uneven surfaces, or

other defects that might be detrimental to the

rope; and

Extreme deep wear.

Sheaves should also be checked to make sure

that it turns freely, is properly aligned, has no

broken or cracked flanges and has bearings that

work properly.

9.2.3 Brakes

Brake is a very important component of the

gravity ropeway, if it does not come into effect at

the right time, the loaded trolley will ram into the

45