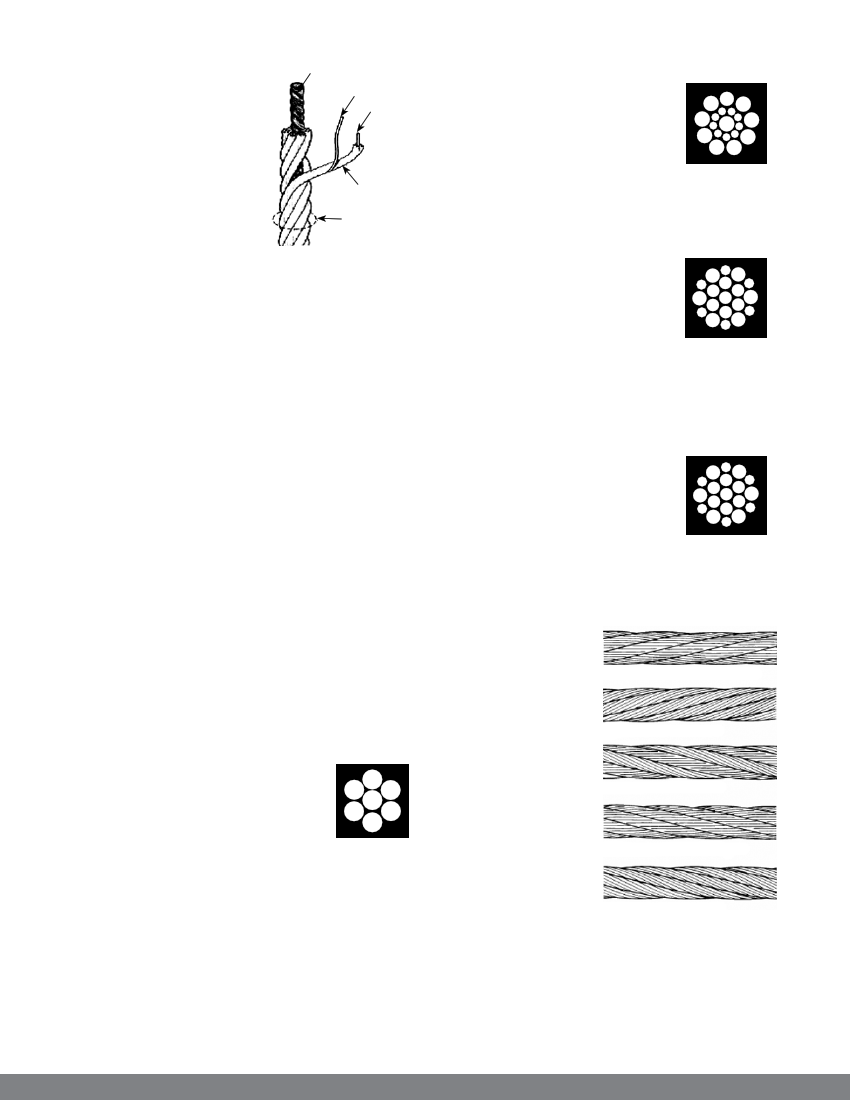

GRAVITY GOODS ROPEWAY

core

on a wire-centre rod.

They are normally

wire

center wire

drawn from bigger

diameter steel rods

in such a way that the

rods pass through a

series of dyes which

progressively reduces

strand

wire rope

their diameters to

form wires. They

are usually made up of high steel carbon.

9. Core: The core of a wire rope is made up of

either textile fibres or steel wires. It provides

an elastic bed preventing internal friction and

sliding of strands twisting around it.

10. Strand: A strand is produced by twisting a

bundle of wire in a particular configuration

and direction. The number of wires and the

number of layers in a strand depend on the

usage frequency of the rope. The centre wire

of a strand is known as “King wire”.

11. Strand constructions: Strands are designed

with various combinations of wires and wire

sizes to produce the desired resistance to

fatigue and abrasion. Generally, a small

number of large wires will be more abrasion

resistant and less fatigue resistant than a

large number of small wires. Various types of

wire-strands are elaborated below:

11.1 Single size: This basic

strand construction has

wires of the same size

winded around a centre

as shown in the diagram

at the right.

11.2 Seale: This consists of a number of

larger outer wires with the same number

of smaller inner wires winded around

a core wire. This provides excellent

abrasion resistance but less fatigue

resistance. When used

with an Independent

Wire Rope Core (IWRC),

it offers excellent

crush resistance over

drums. The Seale type

rope construction with IWRC core is

commonly used for gravity ropeways.

11.3 Filler wire: This consists

of a combination of two

layers of the same wires

winded around the core

wire. Small wires are

used to fill spaces between the larger

wires to produce crush resistance with

a good balance of strength, flexibility

and resistance to abrasion.

11.4 Warrington: As in the

diagram shown at right,

the outer layer of large

and small wires placed

alternately provides

good flexibility and

strength but low abrasion and crush

resistance.

12. Lays : “Lays”

of a wire rope

is simply a

Left lay regular lay

description of

direction as how

the wires and

Left lay lang lay

strands are placed

or laid during

manufacturing.

Right Alternate Lay

Right lay means

the strands laid

from left to the

Right lay regular lay

right across the

rope. Left lay

means just the

Right lay lang lay

opposite - strands

laid from right to the left. Regular lay and

Lang’s lay differentiate the way the wires are

laid within each strand.

132