Industrial uses of lead

Contents

Introduction

The Toxics Use Reduction Institute is a Massachusetts government research entity that has used the unique usage data from the state pollution and prevention program to create selected chemical fact sheets (Industrial uses of lead) . The following is from the Turi Lead Fact sheet.

In 2004, Massachusetts manufacturers used more than 3.5 million pounds of lead and lead compounds.

Lead: Use Nationally and in Massachusetts

The total global industrial consumption of lead in 2003 was estimated to be 15.1 billion pounds, and the U.S. consumption of lead in 2003 was estimated to be 3.06 billion pounds. The greatest use of lead is in lead-acid batteries, however lead-acid batteries are not manufactured in Massachusetts.

Lead has a low melting temperature (327° C) for a metal and is extremely malleable, which enables easy casting, shaping, and joining of lead products. Lead can be recycled as a secondary raw material from lead-acid batteries and other lead products.

The high density of lead is desirable for several product categories including weighting applications, and shielding against sound, vibration, and radiation.

Lead compounds have different physical properties than elemental lead, and are used for various products. The major lead compounds used in commerce are lead oxide (PbO), lead tetraoxide (Pb3O4), basic lead carbonate (white lead), tribasic lead sulfate, and dibasic lead phthalate.

Lead and its compounds have many desirable material properties and a variety of uses. Major products/uses of lead in the US include: batteries, ammunition, glass, heat stabilizer in plastics and resins, metal finishing, electronics (solder, board surface finish, components), sheet lead (sound barriers, roof flashing, radiation shielding), bulk metal (castings, weighting applications, ammunition), and pigments. For example, the reactions of lead oxide in dilute sulfuric acid are fundamental to the operation of a lead-acid battery.

The total U.S. consumption of lead in 2005 for various uses is shown in Table 1.

|

| ||

| Use | U.S. Consumption in 2005 (Million Pounds) | Percentage of Total U.S. Consumption |

|---|---|---|

| Storage batteries | 2,580.0 | 88.4% |

| Ammunition | 122.6 | 4.2% |

| Miscellaneous Uses | 65.8 | 2.3% |

| Sheet lead | 58.0 | 2.0% |

| Casting metals | 39.0 | 1.3% |

| Oxides | 28.2 | 1.0% |

| Solder | 16.7 | 0.6% |

| Billets, ingots | 4.2 | 0.1% |

| Extruded products | 2.4 | 0.1% |

| Bearing metals | 2.4 | 0.1% |

| TOTAL | 2,919.3 | 100.0% |

Table 2 summarizes the difference in reported use of lead in Massachusetts from 1990 to 2004. It is important to note that the reporting threshold for lead was lowered from 10,000 pounds to 100 pounds starting in 2001, so the number of facilities reporting in 2004 is significantly higher than in 1990.

Since the reporting threshold was lowered in 2001, many companies that were previously exempt entered the reporting process. For example, 59 electronics facilities, 31 metal products facilities, and 15 plastics/rubber companies entered the reporting process since 2001 due to this lower reporting threshold. In addition, concrete manufacturers and electricity generators facilities were not required to report in 1990.

|

| ||||

| 1990 | 2004 | |||

|---|---|---|---|---|

| Use Category | Number of Facilities | Total Use (1,000 lb) | Number of Facilities | Total Use (1,000 lb) |

| Batteries | 1 | 260.0 | 0 | 0 |

| Ceramic Glazes | 1 | 165.9 | 1 | 59 |

| Colorants | 2 | 293.8 | 5 | 467.7 |

| Concrete - Ready Mixed and Concrete Products | 0 | 0 | 38 | 11.5 |

| Electricity Generation | 0 | 0 | 15 | 2,803.5 |

| Electronics | 5 | 115.6 | 64 | 169.6 |

| Glass-based Products | 3 | 580.1 | 7 | 166.9 |

| Inorganic chemicals | 0 | 0 | 2 | 3.1 |

| Metal Products | 11 | 366.6 | 41 | 784.9 |

| Paints and coatings | 2 | 37.5 | 2 | 141.9 |

| Paper, Paperboard and Coated Paper | 2 | 54.6 | 4 | 2.3 |

| Plastic or Rubber Products and Compounding | 13 | 3,149.9 | 21 | 1,675.1 |

| Silverware and Hollowware Tableware | 2 | 110.9 | 2 | 2.1 |

| Wire and Cable Insulation and Jacketing | 9 | 2,018.5 | 18 | 2,544.5 |

| Recycling of Mercury-Containing Products and Waste Oil | 0 | 0 | 3 | 13.0 |

| Miscellaneous | 0 | 0 | 7 | 7.5 |

| TOTAL | 51 | 7,153.5 | 230 | 8,852.75 |

The Metal Products sector, which represented less than 9% of the total amount of reportable lead in Massachusetts in 2004, experienced the second highest increase (97%) in lead use. This was mainly due to 31 new facilities reporting in this sector because of the impact of the lowered reporting threshold for lead in 2000.

Of the primary industry sectors reporting us of lead in Massachusetts in 2004, the metal products industries saw an increase in reportable amounts of lead of 114%, colorants (used primarily in the wire and cable coating industry) increased by 59%, and the wire and cable jacketing and insulation industry increased by 26%. Plastics and rubber products and compounds decreased its overall reportable use of lead by 47% from 1990 to 2004.

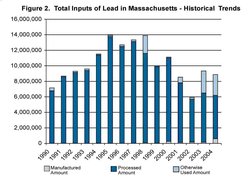

The annual reported quantities from 1990 to 2004 in absolute amount of inputs and outputs in Massachusetts are shown in Figures 2 and 3. The term “inputs’ is the total use, consisting of amounts that are “manufactured” or “processed”, as well as amounts that are “otherwise used” (i.e., ancillary uses that do not become incorporated into the final product).

Outputs include lead and lead compounds that are “generated as byproduct” (i.e., all non-product material created by a process line prior to release, on-site treatment, or transfer) and the amount of lead and lead compounds that are “shipped in or as product”. As shown in Figure 3, majority of lead and lead compounds used are processed and subsequently shipped in product, though the trend especially since 2000, has been towards a higher percentage of lead and lead compounds to be generated as byproduct.

As shown in Figures 2 and 3, both inputs and outputs significantly increased during the time period from 1990 to the mid 1990’s with peak values occurring in 1998. For the period 1998 to 2004, there has been a significant reduction in the Commonwealth for both inputs and outputs of lead and lead compounds. Specifically, from 1998 to 2004 the amount of lead and lead compounds “processed” was reduced by 51.3%, while the amount “shipped in or as product” over the same time period was reduced by 49.6%.

There was a major increase in lead “otherwise used” and “generated as byproduct” in 1998 because a new filer, Clean Harbors Environmental Services, was managing significant amounts of lead-bearing waste. Over the next few years, their use of lead decreased and was reclassified as “processed”.

There was also a significant increase in lead reported as “otherwise used” and “generated as byproduct” in 2003 and 2004 because Municipal Solid Waste Combustors were required to report for the first time (as “waste to energy” facilities, their use is included in “electricity generation” in Table 2)[1].

Regulatory Context

Lead has been listed as a pollutant of concern to EPA’s Great Waters Program due to its persistence in the environment, potential to bioaccumulate, and toxicity to humans and the environment. The National Ambient Air Quality Standard (NAAQS) are set by the U.S. EPA for pollutants that are considered to be harmful to public health and the environment. The NAAQS for lead is 1.5 micrograms per cubic meter (?g/m3).

The U.S. Environmental Protection Agency (EPA) created a maximum contaminant action level for lead in drinking water of 0.015 millgrams per liter (mg/l). EPA has not established an inhalation reference concentration (RfC) or an oral Reference Dose (RfD) for elemental lead or inorganic lead compounds. EPA has, however, established an RfD for tetraethyl lead of 1 x 10-7 mg/kg body weight per day.

The following occupational threshold limits have also been established:

- NIOSH Recommended Exposure Limit for an 8 to 10 hour time-weighted-average exposure = 0.10 mg/m3.

- NIOSH Immediately Dangerous to Life or Health = 100 mg/m3

- OSHA Permissible Exposure Limit for an 8 hour work day = 0.5 mg/m3.

- ACGIH Threshold Limit Value = 0.5 mg/m3 over an 8 hour work shift.

Restrictions on Lead in Products

There are various restrictions on the use of lead in products that have been promulgated by some international, national and state agencies. These include:

- The European Union’s RoHS directive restricts the use of lead in many electronics applications if present in a homogenous material in amounts exceeding 0.1% by weight.

- In the US, the Consumer Products Safety Commission (CPSC), under the Federal Hazardous Substance Act, has banned most “paint and surface coatings containing more than 0.06% lead, and furniture, toys and other articles intended for use by children that are coated with such paint.”

- In addition, any toy or article intended for use by children that is likely to expose the child to a sufficient amount of lead to present a hazard, according to CSPC’s rules, is banned.

- Several states in the Northeast have banned the use of certain lead sinkers for fishing. Massachusetts still allows the use of lead fishing sinkers except in the Quabbin and Wachusett Reservoirs.

- In light of recent disclosures of lead in paint on children’s toys, in children’s jewelry, in vinyl products such as lunch boxes and bibs, and in lipsticks, there is growing concern about the need for more comprehensive regulations, testing and enforcement of lead restrictions in consumer products[2].

Further Reading

- The Toxics Use Reduction Institute homepage

- Five Chemicals Study

Endnotes

Editor's Note

- The Encyclopedia of Earth article "Public Health Statement for Lead" relates to this entry.

Citation

Institute, T., Morose, G., Harriman, E., Civie, P., & Tenney, H. (2013). Industrial uses of lead. Retrieved from http://editors.eol.org/eoearth/wiki/Industrial_uses_of_lead- ↑ European Commission Enterprise Directorate-General 2004, Final Report: Advantages and Drawbacks of Restricting the Marketing and Use of Lead in Ammunition, Fishing Sinkers and Candle Wicks.–Gabby, P.N.. 2007, “Lead -- 2005” in United States Geological Survey Minerals Yearbook.–Graboski, D. 1998, Wire and Cable Industry, Furman Selz LLC, 230 Park Avenue, New York 10169.–Grossman, D. 2006, Handbook of PVC Formulating, John Wiley & Sons.–Linak, E. & Yagi, K. 2003, “Polyvinyl Chloride (PVC) Resins” in Chemical Economics Handbook SRI International.–Minnesota Office of Environmental Assistance (MOEA), <a href="http://www.moea.state.mn.us" rel="nofollow" title="http://www.moea.state.mn.us">Minnesota Office of Environmental Assistance (MOEA) website</a>. 2006.–Shedd, K.B. 2006, Mineral Industry Surveys: Tungsten in December 2005, United States Geological Survey.–United States Fish & Wildlife Service (USFWS) & New Hampshire Fish and Game Department, <a href="http://wildlife.state.nh.us" rel="nofollow" title="http://wildlife.state.nh.us">Let’s Get the Lead Out</a>. 2006.– Wickson, E.J. 1993, Handbook of PVC Formulating, John Wiley & Sons.

- ↑ National Institute for Occupational Safety and Health (NIOSH) 2004, Pocket Guide to Chemical Hazards.–U.S. EPA, National Ambient Air Quality Standards.