In situ leach (ISL) mining of uranium

This EOE article is adapted from an information paper published by the World Nuclear Association (WNA). WNA information papers are frequently updated, so for greater detail or more up to date numbers, please see the latest version on WNA website (link at end of article).

Contents

- 1 IntroductionConventional mining involves removing mineralized rock (In situ leach (ISL) mining of uranium) (ore) from the ground, breaking it up and treating it to remove the minerals being sought.

- 2 ISL Wellfield

- 3 Uranium Recovery

- 4 Remote Ion Exchange

- 5 ISL in Australia

- 6 Environment & Health

- 7 Further Reading

IntroductionConventional mining involves removing mineralized rock (In situ leach (ISL) mining of uranium) (ore) from the ground, breaking it up and treating it to remove the minerals being sought.

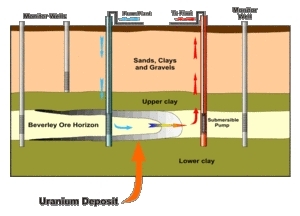

In situ leaching (ISL), also known as solution mining, or in situ recovery (ISR) in the USA, involves leaving the ore where it is in the ground, and recovering the minerals from it by dissolving them and pumping the pregnant solution to the surface where the minerals can be recovered. Consequently there is little surface disturbance and no tailings or waste rock generated. However, the orebody needs to be permeable to the liquids used, and located so that they do not contaminate ground water away from the orebody.

Uranium ISL uses the native groundwater in the orebody which is fortified with a complexing agent and in most cases an oxidant. It is then pumped through the underground orebody to recover the minerals in it by leaching. Once the pregnant solution is returned to the surface, the uranium is recovered in much the same way as in any other uranium plant (mill).

In Australian ISL mines (Beverley and the soon to be opened Honeymoon Mine) the oxidant used is hydrogen peroxide and the complexing agent sulfuric acid. Kazakh ISL mines generally do not employ an oxidant but use much higher acid concentrations in the circulating solutions. ISL mines in the USA use an alkali leach due to the presence of large quantities of acid-consuming minerals such as gypsum and limestone in the host aquifers.

In either the acid or alkali leaching method the fortified groundwater is pumped into the aquifer via a series of injection wells where it slowly migrates through the aquifer leaching the uranium-bearing host sand on its way to strategically placed extraction wells where submersible pumps pump the liquid to the surface for processing.

ISL uranium mining was first tried on an experimental basis in Wyoming during the early 1960s. The first commercial mine began operating in 1974. Today most US uranium production comes from ISL mining. Several projects are licensed to operate there, (in Wyoming, Nebraska and Texas) and most of the operating mines date from the 1990s. They are small (under 1000 t/yr) but they supply most of the US uranium production. About 26% of world uranium production is by ISL (including all Kazakhstan and Uzbekistan output).

ISL can also be applied to other minerals such as copper and gold.

Uranium deposits suitable for ISL occur in permeable sand or sandstones, confined above and below by impermeable strata, and that are below the water table. They may either be flat, or "roll front", - in cross section, C-shaped deposits within a permeable sedimentary layer.

Such deposits were formed by the lateral movement of groundwater bearing oxidized uranium minerals through the aquifer, with precipitation of the minerals occurring when the oxygen content decreased, along extensive oxidation-reduction interfaces. The uranium minerals are usually uraninite (oxide) or coffinite (silicate) coatings on individual sand grains. The ISL process essentially reverses this ore genesis, in a much shorter time frame.

There are two operating regimes for ISL, determined by the geology and groundwater. If there is significant calcium in the orebody (as limestone or gypsum), alkaline (carbonate) leaching must be used. Otherwise, acid (sulfate) leaching is generally better. In this case the leach solution is at a pH of 2.5 - 3.0, about the same as vinegar.

Techniques for ISL have evolved to the point where it is a controllable, safe, and environmentally benign method of mining which operates under strict operational and regulatory controls.Due to the low capital costs (relative to conventional mining) it can often be a more effective method of mining low-grade uranium deposits.

ISL Wellfield

The design of ISL wellfields varies greatly depending on the local conditions such as permeability, sand thickness, deposit type, ore grade and distribution. Whatever the type of pattern used, there is a mixture of injection wells, to introduce the leach solution to the ore body, and extraction wells with submersible pumps used to deliver pregnant solution to the processing plant. Wells are typical of normal water bores.

Where large sheet-like deposits exist, such as in Kazakhstan, rows of injection wells interleafed with rows of extraction wells can be used cost effectively. This pattern has a relatively low installation cost and is simple to install. However the time taken to recover the uranium under leach is extended due to the large distances between the well types (typically 50-60m).

In most western applications (and Kazakh operations in channels narrower than 60m) closer spaced patterns are employed to recover the uranium at a faster rate (per unit area) than the alternating line patterns. These are either 5-Spot patterns (usually 20-30m between like wells) or 7-Spot patterns (usually 30-40m diameter).

These tighter patterns are generally used effectively in narrower palaeochannel type deposits where flexibility in the installation is needed. The installed costs of these wellfields are generally higher, so to ensure maximum recovery of the uranium, the following secondary measures can be taken:

- Flow reversals - converting injection wells to extraction wells where required.

- Infill wells - to increase recovery from higher grade portions of the wellfield.

In Australia installed wells are hydraulically pressure tested to 150% of their design operating pressure to ensure no leakage to overlying [[aquifer]s] is possible. Operating wells are also re-tested after a period of 12 months of operation.

Whichever pattern type is used, the wellfields (usually a production unit that feeds to a single header house) are progressively established over the orebody as uranium is depleted. A series of monitor wells are situated around each mineralized zone to detect any movement of mining fluids outside the mining area. The wells are cased to ensure that liquors only flow to and from the ore zone and do not affect any overlying aquifers.

In the USA the production life of an individual ISL well pattern is typically one to three years. Most of the uranium is recovered during the first six months of the operation. The most successful operations have achieved a total overall recovery of about 80% of the ore, the minimum is about 60%. In Australia individual well patterns can operate from between 6 and 18 months with target recoveries of around 70% in 12 months.

The progressive flow through the aquifer also traps clay and silt in the permeable sediments. These can be dislodged to some extent by using higher pressure injection or by reversing the flow between injection and production wells. However the flow capacity of injection wells is generally always on a downward trend thought the life of the well.

Uranium Recovery

The submersible pumps initially extract native groundwater from the host aquifer prior to the addition of uranium complexing reagents (acid or alkaline) and an oxidant (hydrogen peroxide or oxygen) before injection into the wellfield. The leach liquors pass through the ore to oxidize and dissolve the uranium minerals in situ.

Depending on the type of leaching environment used the uranium will be complexed as either a uranyl sulfate, predominantly UO2(SO4)34-, in acid leach conditions or a uranyl carbonate, predominantly UO2(CO3)34-, in a carbonate leach system. This can then be precipitated with an alkali, e.g., as sodium or magnesium diuranate.

IX is used in the vast majority of ISL operations in Kazakhstan, the USA and Australia. In terms of operating and capital costs IX is the preferred processing option. In situations where the groundwater has a high concentration of ions that may compete with the uranyl complexes for active resin sites, such as chloride and nitrates, the use of IX becomes unattractive due to low uranium loadings on the resin. (As a general rule if chloride concentrations in the groundwater is above 5-6 g/L the capture of uranium by IX becomes uneconomical.) SX is better with very saline groundwater (17-20 g/L) as at Honeymoon, though other process challenges can arise.

Further treatment for IX in Australia involves stripping the uranium from the resin either with a strong acid or chloride solution or a combination of both in a batch operation. In Kazakh operations the resins are generally stripped with a nitrate solution in a semi-continuous cycle. There are advantages and disadvantages with both systems and the applicability of either will again depend on the quality of the groundwater used. The pregnant solution produced by the stripping cycle is then precipitated by the addition of ammonia, hydrogen peroxide, caustic soda or caustic magnesia. Peroxide products can be dried at low temperatures to produce a product containing about 80% U3O8. However ammonium or sodium diuranate products must be dried at high temperatures to convert the product to 100% U3O8.

SX is a continuous loading/stripping cycle involving the use of an organic liquid (usually a kerosene-based product) to carry the extractant which removes the uranium from solution. The uranium is then stripped from the loaded organic liquid using ammonia followed by an ammonia precipitation. The resultant slurry is then dried at high temperature as per the IX process.

After recovery of the uranium, the barren solution is re-fortified with oxidant and complexing agent before being returned to the wellfield via the injection wells. However, a small flow (about 0.5%) is bled off to maintain a pressure gradient in the wellfield and this, with some solutions from surface processing, is treated as waste. This waste water contains various dissolved ions such as chloride, sulfate, sodium, radium, arsenic and iron from the orebody and is reinjected into approved disposal wells in a depleted portion of the orebody. This bleed of process solution ensures that there is a steady flow into the wellfield from the surrounding aquifer, and serves to restrict the flow of mining solutions away from the mining area.

Acid consumption in acid leach environments is variable depending on operating philosophy and geological conditions. In general, the acid consumption in Australian ISL mines is about four percent of that used in a Kazakh mine (per kilogram of uranium produced). Unit power consumption is about 16 kWh/kg U3O8 in Australia and around 28 kWh/kg in Kazakhstan.

Remote Ion Exchange

For very small which are amenable to ISL mining, a central process plant may be distant from the mined orebody, where a satellite plant will be set up. This does no more than provide a facility to load the ion exchange (IX) resin so that it can be trucked to the central plant in a bulk trailer for stripping. Hence very small deposits can become viable, since apart from the wellfield, little capital expenditure is required at the mine site.

Remote ion exchange is being used in Wyoming and Texas in the USA, in the former as toll milling.

ISL in Australia

There are two ISL uranium mining projects in Australia—Beverley and Honeymoon, both in the Lake Frome area of South Australia between Broken Hill and the northern Flinders Ranges.

The Beverley deposit is 520 km north of Adelaide, in a buried river bed (palaeochannel). At least three ore lenses in uncemented fluvial sands lie at a depth of 110-130 meters, over some 4 km. They contained at least 21,000 tonnes of uranium oxide at 0.18% grade, making it currently the largest Australian deposit of its kind.

A successful field leach trial in 1998 established the commercial viability of the project. A new draft Environmental Impact Statement (EIS) was released for public comment in 1998 with environmental and other approvals being given early in 1999. Production began in November 2000 and the mine is licensed to export 1500 t/yr U3O8.

At Honeymoon, 75 km NW of Broken Hill, the uranium deposit occurs in porous sandstone at a depth of 100-120 meters and extending over about 150 hectares of a buried river bed (palaeochannel). It contains U3O8 averaging 0.15% and amenable to ISL.

Honeymoon was discovered in 1972. Plans were then developed in the 1980s to extract the uranium oxideby ISL following first field tests in 1975 and 1977. Draft and Final Environmental Impact Statements were produced, and both South Australian and Commonwealth environmental approval was subsequently obtained in 1981 for production to 450 t/yr. Field tests of the in situ leaching process were carried out and a $3.5 million, 110 t/yr pilot plant was built and remains on site, but the project was abandoned in 1983 due to the "Three mines" policy then in effect.

UraniumOne now plans to bring Honeymoon and the associated deposits into production at about 400 t/yr U3O8 equivalent early in 2008 and construction has commenced.

The company also holds leases at Billaroo West (including Gould Dam), 80 km northwest of Honeymoon, with further resources of U3O8 amenable to ISL.

Environment & Health

At established operations overseas, after ISL mining is completed, the quality of the remaining groundwater must be restored to a baseline standard determined before the start of the operation so that any prior uses may be resumed. Contaminated water drawn from the aquifer is either evaporated or treated before reinjection.

In contrast to the main US operations, the water quality at the Australian sites is very poor to start with, and it is quite unusable. At Beverley the groundwater in the orebody is fairly saline and orders of magnitude too high in radionuclides for any permitted use. At Honeymoon the water is even more saline, and high in sulfates and radium. When oxygen input and leaching are discontinued, the water quality reverts to its original condition over time.

Upon decommissioning, wells are sealed or capped, process facilities removed, any evaporation pond revegetated, and the land can readily revert to its previous uses.

The usual radiation safeguards are applied at an ISL mining operation, despite the fact that most of the orebody’s radioactivity remains well underground and there is hence minimal increase in radon release and no ore dust. Employees are monitored for alpha radiation contamination and personal dosimeters are worn to measure exposure to gamma radiation. Routine monitoring of air, dust and surface contamination is undertaken.

Further Reading

- WNA paper on In situ leach (ISL) mining of uranium

- Ackland, M.C. et al, 1999, The future of solution mining, ANA Conference paper.

- Dobrzinski, I, 1997, Beverley and Honeymoon Deposits, MESA Journal 5, April 1997.

- Heathgate Resources, 1998, Beverley Uranium Mine Environmental Impact Statement.

- Hunter, T, 2001, Developments in Uranium Solution Mining in Australia, ANA Conference paper.

- Southern Cross resources, 2000, Honeymoon Uranium Project Environment Impact Statement.

- Szymanski, W N. 1993, Energy Information Administration, Uranium Industry Annual.