Cool paving

Contents

- 1 Introduction Cool pavements are a means of reducing the urban heat island effect (Cool paving) . The term refers to materials chosen to reduce pavement temperature by increasing pavement reflectivity or controlling temperature by other means through choice of materials and engineering design.

- 2 Benefits of cool paving

- 3 Mechanisms of cool pavements

- 4 Types of cool pavements

- 5 Further reading

Introduction Cool pavements are a means of reducing the urban heat island effect (Cool paving) . The term refers to materials chosen to reduce pavement temperature by increasing pavement reflectivity or controlling temperature by other means through choice of materials and engineering design.

Pavements are critical to transportation in all of its aspects – walking, riding in passenger vehicles, carrying goods in commercial vehicles, providing mobile services, and parking. They account for a significant percentage of the land surface in an urban area. Analyses in U.S. cities such as Chicago, Houston, Sacramento, and Salt Lake City have shown that pavements for both travel and parking can account for 29 to 39 percent of the land surface in an urban area. A large portion of this is due to parking; in the Houston, Texas, metropolitan area, the parking facilities account for approximately 60 percent of the transportation land use.

By altering land-cover, pavements have important localized environmental effects in urban areas. As with roofing materials, paving materials can reach 150° F in daytime, radiating away this excess heat during both day and night into the air in the urban canopy layer (as well heating stormwater that reaches the pavement surface). Due to the large area covered by pavements in urban areas, they are an important element to consider in heat island mitigation.

Benefits of cool paving

As part of a heat island reduction strategy, cool pavements contribute to the general benefits of heat island mitigation, including increased comfort, decreased energy use, and likely improved air quality (Air quality index). Cool pavements can contribute to local as well as regional comfort improvements. For instance, they help make large paved areas such as parking lots more comfortable for users. Shopping centers may feel this enhances the shopping experience. Additional benefits of cool pavements include:

- Water quality. Cool pavements can create improvements in water quality in two ways. First, permeable roadway pavements and especially parking facilities of all types (asphalt, concrete, and reinforced grass and gravel paving systems) can address water quality problems by reducing the percentage of land covered by impervious surfaces. When combined with water treatment wetlands, these pavements help to act as filters, improving water quality and providing greater groundwater protection. These improvements can translate into savings for urban areas by reducing the need to construct separate sewers or expanded water treatment facilities. Second, both permeable and non-permeable cool pavements can help water quality through reduced heating of runoff. Laboratory tests with permeable pavers have shown reductions in runoff temperatures of two to four degrees Celsius in comparison to conventional asphalt paving.

- Noise. The open pores of permeable pavements have been shown to significantly reduce tire noise.

- Safety. Permeable roadway pavements can enhance safety by reducing water spray from moving vehicles and increasing traction through better water drainage.

- Nighttime illumination. More reflective pavements can enhance visibility at night, potentially reducing lighting requirements and saving both money and energy. European road designers often take pavement color into account when planning lighting needs. Better illumination from lighter pavements is sometimes considered valuable at private establishments as well, for security or customer appeal. Some sources cite nighttime illumination enhancements of 10 to 30 percent with more reflective pavements.

Mechanisms of cool pavements

Given current pavement technology, there are three ways to reduce pavement’s contribution to the urban heat island: by providing a surface that reflects a greater amount of solar radiation; by increasing the ability of the pavement to cool at night; or by allowing a pavement to cool through evaporation by designing and building it as a porous structure.

Albedo

Albedo is measured as the ratio of incident to reflected radiation. Conventional paving materials have albedos ranging from 0.05 to 0.40 when new. Albedo changes over time, due to changing materials properties and the accumulation of dirt and grime on the pavement surface. Thus, while concrete and asphalt pavements have different albedo values when new, the values approach each other once pavements are put in service.

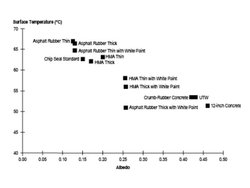

The cool pavement mechanism is based on the idea that by increasing the reflectance of the pavement surface, less sunlight will be absorbed, lowering the daytime temperature of the pavement. This lowered temperature would result in lower air temperature near ground level. The correlation between albedo and pavement temperature is shown in Figure 1 for several pavement surfaces in Phoenix, Arizona.

Pavement is a combination of materials, primarily aggregate (crushed rock or gravel and sand) and a binder to hold the aggregate in place. The binders most commonly used are asphalt and portland cement. The reflectance of a pavement surface depends upon the reflectance characteristics of its materials and the degree to which each material is exposed at the pavement surface. For example, new concrete pavements have relatively high reflectance because of the light color of the portland cement, but reflectance may be reduced if paved with exposed aggregate, as is done for decorative reasons in sidewalks and patios. New asphalt pavements, with a black binder, are generally much less reflective.

Pavement materials change over time due to aging and use. For example, asphalt oxidizes, which lightens its color and increases its reflectance over a period of roughly five to 10 years. However, if allowed to continue, the asphalt effectively “dries out,” becomes brittle, and loses its ability to bind the aggregate, leading to a distress referred to as raveling. If a concrete surface becomes dirty and stained, its reflectance decreases over time. Thus, while concrete pavements generally have higher reflectance than asphalt pavements when they are new, over time their albedo values become closer.

The surface characteristics that affect reflectance also affect the appearance of pavements, and appearance is important to facility owners and motorists for many reasons. Certainly, the contrast in color between pavement surface and lane striping or message markings is important to daytime and nighttime visibility in dry and wet conditions, and affects safety. While owners of facilities where nighttime illumination is important may prefer a lighter pavement color, others like the “crispness” of black pavement with white striping in their parking lots. Some perceive color as a measure of “newness.” These subjective perceptions, discussed in the literature and revealed as well in interviews during this study, are hard to generalize, and may lead to unforeseen public responses to attempts to adjust pavement color for reflectance.

Nighttime Radiational Cooling

A pavement that can lower its temperature quickly during nighttime cooling can reduce the nighttime heat island effect. A consortium led by Arizona State University (ASU) is now experimenting with a composite pavement that has a nighttime temperature lower than that of adjacent portland cement concrete (PCC) pavements. This effect is accomplished by using a rubberized asphalt layer over a PCC base. While this pavement design has been adopted to reduce tire-pavement noise, it also provides a cool pavement benefit and an environmental benefit through the use of recycled materials.

Porosity or Permeability

A porous or permeable ground surface that allows water to percolate through it can exert a cooling effect through evaporation of water in the pavement voids or from beneath (depending on the type of surface and thickness). In addition, permeable surfaces are sometimes more conducive to cooling from convective airflow.

Permeable surfaces have been used to date to control stormwater runoff; the evaporative cooling effect also could be used for heat island reduction. Both asphalt and concrete pavements can be built with porous surfaces, and unbound surfaces (e.g., grass, gravel) can be constructed using grids for reinforcement.

Types of cool pavements

Several candidate technologies for cool pavement have been investigated in past research, including options for new pavement construction, reconstruction, and maintenance and rehabilitation activities.

Conventional Portland Cement Concrete pavement has been proposed as a cool pavement because of its light color and reflectivity. It is used in new construction and reconstruction. The degree of surface reflectivity is affected by both the color of the cement and the type and color of aggregate (particularly as the cement surface becomes worn and the aggregate is exposed).

Concrete additives are routinely used in concrete to enhance its placement during construction or its performance during its service life. One example is the use of slag cement in combination with portland cement. Slag is a byproduct of processing iron or copper ore in a blast furnace. It is obtained from the surface of the molten ore, granulated, and ground to produce a cement that replaces a portion of the portland cement in a concrete mixture. It has several benefits to concrete workability and performance (e.g., improved strength, resistance to aggressive chemicals, better ability to place concrete in hot weather). Among these benefits is a lighter color, which can enhance reflectivity of the finished pavement. In addition, by reducing the amount of portland cement used, slag cement reduces greenhouse gas emissions and energy use in the production of concrete.

Whitetopping consists of a concrete pavement applied over an existing asphalt pavement as a form of maintenance or resurfacing. Conventional whitetopping is more than four inches thick. As a potential cool paving technology, ultra-thin whitetopping (UTW) provides the color and reflectance of concrete over an existing asphalt surface. It has been used on a number of projects across the country for resurfacing road segments, intersections, and parking lots.

Roller-compacted concrete is a specially mixed and placed form of concrete. It employs a very stiff mix that is placed with techniques and equipment much like that used for asphalt pavement. While it results in a strong pavement, its surface is not finished or textured, as is conventional concrete pavement. It is used for heavy hauling roads where speed is not a factor, bulk commodity storage areas.

Light aggregate in asphalt concrete pavement (ACP) refes to increasing the reflectance of ACP by using light-colored aggregate such as limestone. This type of aggregate is available naturally in parts of the country (e.g., Houston area, Florida) and is used in conventional pavement construction and reconstruction. In these locations, the incremental cost of this technology is nil. In other locations, however, the cost to transport such aggregate to the job site is prohibitively expensive.

Chip Seals with Light Aggregate refers to the use of light-colored aggregate in this common preventive maintenance technique on asphalt pavements that could increase the albedo of asphalt-paved surfaces. The cost of such treatment depends on the local availability of suitable aggregate, as noted earlier for ACP. Chip seals are traditionally associated with roads carrying light traffic volumes because of the tendency of the chips (stones) to loosen and be propelled by the action of moving vehicles toward other vehicles, potentially resulting in windshield damage.

Porous pavement and permeable surfaces have been investigated as mechanisms for stormwater discharge control and groundwater management in urbanized areas. Both concrete and asphalt pavements can be built as porous surfaces on roads and parking lots. A porous asphalt surface can improve skid resistance and reduce traffic noise, rutting, and splash due to ponded water on the surface. Noise reduction benefits may decline over time, however, and there may be reduced strength and durability in comparison to conventional surfaces.

Pigments and seals are available to change the color of an asphalt surface to make it lighter. However, these products are expensive, and tend to be used only in special situations where color is a dominant paving criterion. (Pigments also are available for concrete pavements; however, because concrete pavements are already light-colored, pigments are unlikely to improve their “coolness”.)

Rubberized Asphalt is composite pavement design with a rubberized asphalt layer over a PCC base now being used in the Phoenix, Arizona, area. The primary purpose of these pavements is to reduce tire-pavement noise, but current research indicates that they are cooler at night than adjacent PCC. To determine their potential benefits in reducing the heat island, these pavements will be instrumented through an ongoing program by ASU. However, preliminary indications from satellite photos of different types of pavements in the Phoenix metropolitan area suggest promising results from a cool pavement perspective. Because the program has just gotten underway, detailed data are not yet available.

Further reading

Cool Pavement report, EPA.

| Disclaimer: This article is taken wholly from, or contains information that was originally published by, the Environmental Protection Agency. Topic editors and authors for the Encyclopedia of Earth may have edited its content or added new information. The use of information from the Environmental Protection Agency should not be construed as support for or endorsement by that organization for any new information added by EoE personnel, or for any editing of the original content. |