Aeration basin (Pollution)

Contents

Aeration basin

An aeration basin is a holding and/or treatment pond provided with artificial aeration to promote the biochemical oxidation of wastewaters.[1][2][3][4]

There are many other biological processes for the treatment of wastewaters, for example the activated sludge process, trickling filters (also called biofilters) and rotating biological contactors. They all have in common the use of oxygen (or air (Earth's atmospheric air)) and microbial action to biotreat certain water pollutants in municipal and industrial wastewaters.

Methods of aerating basins

There are many methods for aerating a basin:

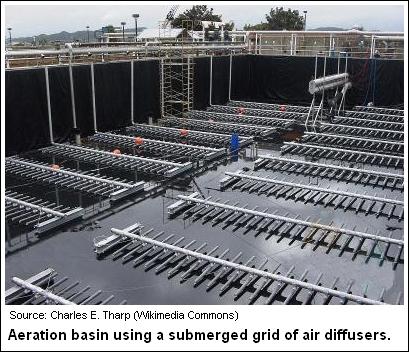

- Injection of compressed air through submerged diffusers, such as in the above photograph.

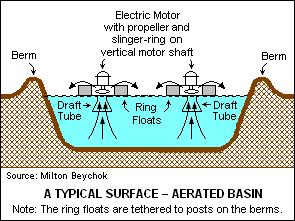

- Motor-driven floating surface aerators, such as in the image inthe next section below.

- Motor-driven fixed-in-place surface aerators

- Motor-driven submerged aerators

Submerged air diffusers

There are two main types of compressed air diffusion systems for applications in aeration basins, namely floating or submerged systems. Both of these systems utilize compressed air diffusers to provide aeration as well as mixing of the wastewater. The diffusers can be suspended slightly above the lagoon floor or they may rest on the bottom as in the above photograph.

Floating surface aerators

Ponds or basins using floating surface aerators achieve 80 to 90% removal of Biochemical Oxygen Demand (BOD) with retention times of one to ten days.[5] The ponds or basins may range in depth from 1.5 to 5.0 meters.[5]

In a surface-aerated system, the aerators provide two functions: they transfer air into the basins required by the biochemical oxidation reactions, and they provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater and microbes). Typically, the floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kg of oxygen (O2) per kilowatt-hour (kWh). However, they do not provide as good mixing as is normally achieved in activated sludge processes and therefore aerated basins do not achieve the same performance level as activated sludge units.[5]

Biochemical oxidation processes are sensitive to temperature and, between zero °C and 40 °C, the rate of biological reactions increases with temperature. Most surface aerated vessels operate at a temperature of between 4 °C and 32 °C.[5]

References

- E.J. Middlebrooks et al (1982), Wastewater Stabilization Lagoon Design, Performance and Upgrading, McMillan Publishing, ISBN 0-02-949500-8.

- G. Tchobanoglous, F.L. Burton and H.D. Stensel (2002), Wastewater Engineering (Treatment Disposal Reuse), 4th Edition, McGraw-Hill and Metcalf & Eddy Inc., ISBN 0-07-041878-0.

- Milton R. Beychok (1967), Aqueous Wastes from Petroleum and Petrochemical Plants, 1st Edition, John Wiley & Sons, Library of Congress Control Number (LCCN) 67019834.

- Editors: Mogens Henze, Mark C.M. van Loosdrecht, George Ekama and Damir Brdjanovic (2008), Biological Wastewater Treatment: Principles, Modelling and Design, International Water Association (IWA), ISBN 1-84339-188-0.

- Milton R. Beychok (1971), "Performance of surface-aerated basins". Chemical Engineering Progress Symposium Series, Volume 67, Issue 107, pp. 322–339. Avalable at the CSI Illumina website