Hydrogen safety, codes, and standards

Contents

- 1 Introduction Hydrogen (Hydrogen safety, codes, and standards) has a long history of safe use in the chemical and aerospace industries. An understanding of hydrogen properties, proper safety precautions and engineering controls, and established rules, regulations and standards are the keys to this successful track record.

- 2 Hydrogen Compared to Conventional Fuels

- 3 Codes & Standards

- 4 Safe Use of Hydrogen

- 5 Challenges of Hydrogen Safety

- 6 Further reading

Introduction Hydrogen (Hydrogen safety, codes, and standards) has a long history of safe use in the chemical and aerospace industries. An understanding of hydrogen properties, proper safety precautions and engineering controls, and established rules, regulations and standards are the keys to this successful track record.

As the use of hydrogen and fuel cell systems expand, codes and standards will be needed to provide the information to safely build, maintain, and operate hydrogen and fuel cell systems and facilities, to ensure uniformity of safety requirements, and to assure local code officials and safety inspectors that sufficient safety standards have been met.

Hydrogen Compared to Conventional Fuels

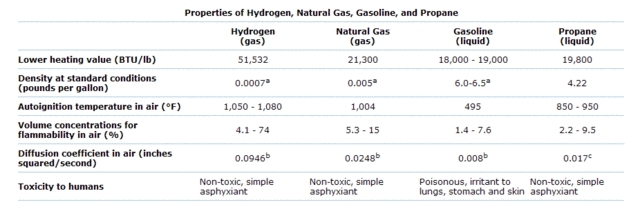

With proper handling and controls, hydrogen can be as safe as, or safer than, other fuels we use today. Safety considerations associated with handling hydrogen include fire, explosion, and asphyxiation. Below is a chart that shows how hydrogen stacks up against some common fuels.

Source: All values are from DOE Alternative Fuels Data Center, except as follows:

- Clean Air Program: Design Guidelines for Bus Transit Systems Using Hydrogen as an Alternative Fuel. U.S. Department of Transportation. DOT-VNTSC-FTA-98-6, 1998. Table 2.1.

- Hydrogen Energy System: A Permanent Solution to Global Problems. T. Nejat Veziroglu. University of Miami. Coral Gables, FL.

- Guidelines on Remediation of Contaminated Sites. Appendix 5.5, "Physical and Chemical Data."

Codes & Standards

Currently thirteen U.S. and two international standards development organizations (SDOs) are developing and publishing the majority of the voluntary domestic codes and standards. These organizations typically work with the public and private sectors to craft standards. In the U.S., the American National Standards Institute (ANSI) coordinates standards development, provides guidance on consensus building, recommends that no more than one standard is developed per technology, and acts as a central point of contact for the harmonization of international standards. Many agencies and organizations are contributing to the development of hydrogen-related codes and standards.

Model Building Codes

The United States has the most comprehensive system in the world to ensure the safety and performance of equipment and buildings for the commercial and residential sectors. This system comprises both voluntary and mandatory development of building codes and equipment standards. As with any new technology, product or system, the existence of applicable codes and standards are an important enabler to commercialization efforts.

Efforts are underway to support activities at the International Code Council and the National Fire Protection Association for the development and adoption of their family of model codes in the 44,000 jurisdictions in the United States.

Key Codes & Standards

Although hydrogen has well-known properties and has significant economic impact in its role as a chemical, it is rarely used as a fuel—except in the space program. A lack of infrastructure and public confidence in its safety must be overcome. A standard can be defined as a set of technical definitions, guidelines, and instructions for designers and manufacturers. The process of developing a standard, like that for developing building codes, is a consensus process involving a number of experts in the field. Development of compatible standards can overcome industrial barriers to commercialization and ensure public acceptance. International standards facilitate world trade by removing technical barriers and represent the core of the World Trade Organization's (WTO's) Agreement on Technical Barriers to Trade.

Safe Use of Hydrogen

By their nature, all fuels have some degree of danger associated with them. The safe use of any fuel focuses on preventing situations where the three combustion factors—ignition source (spark or heat), oxidant (air), and fuel—are present. With a thorough understanding of fuel properties, we can design fuel systems with appropriate engineering controls and establish guidelines to ensure the safe handling and use of a fuel.

A number of hydrogen's properties make it safer to handle and use than the fuels commonly used today. For example, hydrogen is non-toxic. In addition, because hydrogen is much lighter than air, it dissipates rapidly when it is released, allowing for relatively rapid dispersal of the fuel in case of a leak.

Some of hydrogen's properties require additional engineering controls to ensure its safe use. Specifically, hydrogen has a wide range of flammable concentrations in air and lower ignition energy than gasoline or natural gas, which means it can ignite more easily. Consequently, adequate ventilation and leak detection are important elements in the design of safe hydrogen systems. Because hydrogen burns with a nearly invisible flame, special flame detectors are required.

In addition, some metals can become brittle when exposed to hydrogen, so selecting appropriate materials is important to the design of safe hydrogen systems. In addition to designing safety features into hydrogen systems, training in safe hydrogen handling practices is a key element for ensuring the safe use of hydrogen. In addition, testing of hydrogen systems—tank leak tests, garage leak simulations, and hydrogen tank drop tests—show that hydrogen can be produced, stored and dispensed safely.

As more and more hydrogen demonstrations get underway, hydrogen's safety record can grow and build confidence that hydrogen can be as safe as the fuels in widespread use today.

Current Safe Operating Practices

Safe operating practices are established to minimize the known hazards associated with handling hydrogen—fire, explosion, and asphyxiation. Some hazards can be mitigated by hydrogen's unique properties. For example, hydrogen's high dispersion coefficient allows it to dissipate rapidly and makes it virtually impossible for hydrogen to explode in an open area. Other hazards are minimized through operator training and proper system design. Some representative examples include:

- Purging hydrogen systems with an inert gas such as nitrogen is required to avoid the formation of flammable hydrogen/oxygen mixtures.

- Adequate ventilation can minimize eliminate the potential hazard of asphyxiation and the formation of combustible hydrogen/oxygen mixtures.

- Because hydrogen burns with an almost invisible blue flame, special flame detectors are required.

- Safety systems are integrated into hydrogen vehicle design.

To ensure the safety of U.S. Department of Energy (DOE)-sponsored projects, a safety plan, which analyzes an entire process, including the personnel, equipment, and environmental components that are directly and indirectly related to a process, is required by DOE. A safety plan allows for the quantification of risks, which ultimately promotes the insurability and commercial potential of the project.

Typical Safety Guidelines

Decades of handling hydrogen safely for industrial and aerospace applications provide a wealth of practical experience and established guidelines for safe operating practices. In addition, experience gained through hydrogen and fuel cell vehicle demonstrations have resulted in the development of safe practices for maintaining and operating hydrogen and fuel cell vehicles (FCVs). These form the basis of safe operating practices for the Hydrogen, Fuel Cells & Infrastructure Technologies Program. Some of the safe hydrogen practices developed through these experiences include:

- The U.S. National Aeronautics and Space Administration (NASA), with decades of experience using hydrogen as a rocket fuel, has established rigorous safety guidelines for hydrogen system design, materials selection, operations, storage, and transportation, which are summarized in Safety Standard for Hydrogen and Hydrogen Systems.

- The Hydrogen Fuel Cell Engines and Related Technologies Course Manual, produced by the College of the Desert and Sunline Transit Agency with funding from the U.S. Federal Transit Administration, features technical information on the use of hydrogen as a transportation fuel. It covers hydrogen properties, use, and safety as well as fuel cell technologies, systems, engine design, safety, and maintenance.

- As the world's largest supplier of merchant hydrogen and the sole provider of liquid hydrogen for America's Space Shuttle missions, Air Products has summarized the safety precautions for handling gaseous and liquid hydrogen in its Hydrogen Safety Information "Safetygrams". Air Products has also developed hydrogen safety training programs focused on safe handling and properties of hydrogen, and design and operation of hydrogen energy-based systems.

Risk Analysis

Almost any new technology involves some risk. Risks involved in working with hydrogen can be minimized through adherence to standard design parameters for equipment and procedures. The Hydrogen, Fuel Cells & Infrastructure Technologies Program strives for complete system safety in all Program-supported activities. A safety plan, which is comprised of a failure mode and effects analysis (FMEA), a risk mitigation plan, and a communication plan, is used as a criterion for the selection and continuation of supported projects. The three components of a safety plan include:

- The FMEA is a widely used tool in the safety and reliability engineering fields. The main objective of an FMEA is the analysis of every possible failure in a component or a process. The FMEA includes possible results of a failure and peripheral failures that can occur following a component failure. A complete FMEA typically resembles a tree structure and it can be completed in either a top-down or a bottom:up approach. Since specific components are typically not selected during the proposal stage of a project, the functional, or bottom:up approach, is often more suitable for preliminary plans. This method allows for the identification of failures on the subsystem level.

- The risk mitigation plan is used to minimize potential risks. A typical product of an FMEA is a list of potential hazards that require additional attention. The risk mitigation plan entails a prioritization of those hazards, possible resolutions for each hazard, and a list of action items to mitigate those risks. As with the detailed FMEA, the risk mitigation plan is required for all selected projects.

- The communication plan outlines the reports that are made to the Program upon the occurrence of a safety incident. It indicates the severity of incidents that are reported, states the method of reporting, and lists which entities will be notified. The communication plan is required for all selected projects.

Challenges of Hydrogen Safety

From a safety, codes and standards perspective, the fundamental challenges to the commercialization of hydrogen technologies are the lack of safety information on hydrogen components and systems used in a hydrogen fuel infrastructure, and the limited availability of appropriate codes and standards to ensure uniformity and facilitate deployment. Some of the specific challenges include:

Limited Safety Data for Hydrogen Systems. Only a small number of hydrogen technologies, systems and components are in operation and many are in the pre-commercial development phase and still proprietary. As such, only limited data are available on the operational and safety aspects of these technologies. In addition, the historical data used in accessing safety parameters for the production, storage, transport, and utilization of hydrogen are several decades old and need to be assessed and validated.

Liability/Insurability Issues. Lawsuits and insurability are serious concerns that could affect the commercialization of hydrogen technologies. New technologies not yet recognized in codes and standards will have difficulty in obtaining reasonable insurance, and may not be approved in some cases.

Lack of Understanding of Hydrogen Systems. There is currently a general lack of understanding of hydrogen and hydrogen system safety needs among local government officials, fire marshals, and the general public. In addition, there is no comprehensive Handbook of Best Management Practices for hydrogen safety for officials to refer to.

Consensus National Agenda on Codes and Standards. The code development process is voluntary, so the government can affect its progression, but buy-in is ultimately required from code publishing groups. Competition among standards/code development organizations complicates the process. Other challenges include the large, diverse number of state/local jurisdictions in the U.S, limited state funds for new codes, and training differences for code officials.

International Competitiveness. International code development is usually complicated and difficult to achieve because of international competitiveness and licensing issues. Governments have a limited role in the development of International Standards Organization (ISO) standards. Inadequate representation by government and industry at international forums leads to difficulties in promoting the findings of international technical committees to domestic industry experts.

Current Large Footprint Requirement for Hydrogen Fueling Stations. Lack of technical data for underground and above ground storage, set back and other safety requirements in effect for the use of hydrogen in industrial applications, and the current lack of technical data for hydrogen storage result in excessively large footprints. Insurance rates are tied to current codes and standards.

Further reading

| Disclaimer:This article is taken wholly from, or contains information that was originally published by, the Department of Energy. Topic editors and authors for the Encyclopedia of Earth may have edited its content or added new information. The use of information from the Department of Energy should not be construed as support for or endorsement by that organization for any new information added by EoE personnel, or for any editing of the original content. |