Electric vehicle (Energy)

Contents

Electric vehicle

Electric vehicles and hybrid electric vehicles which are able to be charged from mains power will necessarily increase the demand for base-load power from grid systems. A common misconception of electric vehicles is that such vehicles are without air pollution or greenhouse gas impacts to the environment; in fact, electric vehicles produce similar levels of air pollutant emissions and greenhouse gases as conventional vehicles, since the power is chiefly generated from conventional power plants feeding the grid. In addition, production of the battery for electric vehicles contributes about 17 tons of carbon dioxide, giving the electric car a huge carbon disadvantage upon day one of its operation. (Dai et al, 2019) Only if there is a significant new development of nuclear power plants or other non-fossil plants will electric vehicles be able to draw large enough power supplies to avoid such air pollution impact. Current hybrid cars are generally as efficient (if not more energy efficient) as plug-in versions which derive most of their power from the grid; moreover, the efficiency of hybrid vehicles and conventional internal combustion engines are fundamental deterrents to more widespread use of full electric vehicles. Moreover, the development of such full electric vehicles depends critically on new breakthroughs in battery technology.

As outlined in the paper Transport and the Hydrogen Economy, nuclear power is relevant to road transport and motor vehicles in three respects:

- Hybrid and full electric vehicles potentially use off-peak power from the grid for recharging (but generally do not yet do so). This is electromobility.

- Nuclear heat can be used for production of liquid hydrocarbon fuels from coal.

- Hydrogen for oil refining and for fuel cell vehicles may be made electrolytically, and in the future, thermochemically using high-temperature reactors.

Pedestrian deaths

Noise pollution is greatly reduced for electric vehlcles, compared to conventional gasoline or diesel engine vehicles; however, pedestrian death rates are increasing due to lesser ability of pedestrians to hear oncoming electric vehicle approach. The National Highway Traffic Safety Administration conducted a large scale twelve state study that showed electric vehicles are 35 percent more likely to cause a pedestrian fatality. The pedestrian deaths by electric vehicles are particularly high for children and seniors. Pedestrian deaths had declined steadily since 1980 had declined steadily until 2010, when electric cars were introduced; in the next nine years pedestrian deaths increased by 70.1 percent. Bicyclist deaths due to electric vehicles demonstrates an even higher percentage kill rate compared to pedestrians. Most dramatically as electric vehicle adoption accelerated in 2020, pedestrian deaths per vehicle mile increased an astonishing twenty percent. Presently in 2021, electric vehicles account for over 3000 excess pedestrian deaths in the USA.

Electromobility

Hybrid electric vehicles are powered by batteries and an internal combustion (IC) engine. They may be parallel hybrid technology, with both batteries and/or engine propelling the vehicle (with sophisticated controls), or series hybrids, with the engine simply charging the battery. Both types may be capable of plugging-in to mains electricity from the grid, in which case they need much larger battery packs. For the series hybrid, the engine then is used only when needed, so it can run at optimum speed and efficiency.

Higher capital cost of hybrids is offset by slightly lower running costs and lower emissions. Better batteries will allow greater use of electricity in driving, and will also mean that charging them can be done from mains power, as well as from the motor and regenerative braking. These plug-in electric hybrid vehicles (PHEV) are on the verge of being practical and economic today.

Widespread use of PHEVs which get much of their energy from the electricity grid overnight at off-peak rates would increase electricity demand and mean that a greater proportion of a country's electricity could be generated by base-load plant and hence at lower cost. Where the plant is nuclear, it will also be emission-free.

Greater use of electric vehicles (EV), predominantly with off-peak charging, will have the same effect.

Partnerships are starting to emerge between power and automotive companies in anticipation of wider use of PHEVs and EVs in Europe. Deploying them is more of a challenge in Europe than in USA because most cars are not garaged overnight and so must be charged elsewhere, often more rapidly. In 2007 EdF and Toyota set up a collaborative trial in France using PHEVs (see below), and in 2008 RWE and Daimler announced an EV trial in Berlin involving 100 cars. The French trial was then extended to UK, with 50 EdF staff vehicles involved. Daimler already has Smart EVs on test in London. Part of the corporate collaboration relates to how users are billed, as well as how the cars are recharged.

Nissan has been developing alliances with local governments and infrastructure companies in several countries so as to commercialize its electric cars in 2010.

In October 2008, EdF announced partnerships with Peugot Citroen (which is already working with Mitsubishi on electric {C}powertrains) and also Renault-Nissan Alliance related to EVs and PHEVs. The former focuses on recharging systems and protocols and the latter on creating a large-scale zero-emissions individual transport system based on EVs. EdF claims already to operate the world's largest fleet of EVs – 1500 vehicles, and is now developing a new generation of innovative charging stations.

Volkswagen, along with Nissan-Renault and others, is pushing forward with EVs and series PHEVs. It sees fuel cell vehicles as "a pipedream."

Hybrid electric vehicles

Hybrid electric vehicles have been on the market for several years and are now fairly sophisticated and reliable, and are consequently in high demand. However, today's hybrids still depend on liquid fuels, while using regenerative braking to increase efficiency. Nevertheless as of 2022 the hybrid electric vehicle is more carbon efficient than an all electric vehicle, since the carbon cost of manufacturing an electric vehicle battery ranges as high as 7300 kilograms of carbon dioxide. There is a further high carbon cost to mining lithium needed for an all electric vehicle, which, when included in life cycle costs, makes the simple hybrid electric vehcle a clearly superior low carbon footprint drive.

Full hybrids have a battery which is charged by an internal combustion (IC) motor (as well as regenerative braking), and drive may be from both or either. They claim much enhanced fuel economy, though figures suggest that there is little advantage over efficient diesel motors. Their significance is mostly as an important step towards plug-in hybrid vehicles.

The Toyota Prius is the best-known hybrid car: it has a 1.5 litre, 57 kW engine, a 10 kW AC generator, a 21 kW nickel metal hydride battery (mass: 45 kg) and a 50 kW AC electric motor, all with sophisticated power electronics and controls. The battery pack is 6.6 Ah at 201 volts (1.3 kWh) and has an 8 year/160,000 km warranty. The range on battery-only is very small however. The vehicle cost is about 30% more than a comparable conventional vehicle. Toyota has a larger vehicle, the Highlander SUV, and Ford has an Escape SUV which is a larger full hybrid unit.

Honda has a different hybrid system, Integrated Motor Assist (IMA), using nickel metal hydride batteries charged (in the Civic and new Insight hybrids) by a 1300cc engine plus regenerative braking. The batteries mainly assist acceleration via a thin 10 or 20 kW electric motor/generator between the 60 kW engine and transmission. Unlike Toyota and Ford systems, IMA cannot function to any extent solely on battery power. The whole system has an 8-year warranty.

In New York 13,000 taxis have run a trial with 375 hybrid vehicles and will now convert the whole fleet by 2012.

Mazda's Premacy hydrogen RE people mover has a lithium ion battery pack and a hydrogen-fuelled rotary engine. It appears to be a full parallel hybrid. Mazda's Tribute hybrid is a more conventional full hybrid SUV with nickel hydride battery and 2.3 litre petrol engine.

Plug-in Hybrid Electric Vehicles (PHEV)

A further stage of the hybrid EV technology still under development and likely to have an effect on electricity demand by 2015 is plug-in hybrid-electric vehicles (PHEVs), or "gasoline-optional hybrid-electric vehicles" with a much larger battery than the hybrids and drawing most of their power, at least for short trips, from the electricity grid via the battery rather than liquid fuels. (Incidentally, these can also supply power back to the grid when they are plugged in.) However, in contrast to the hybrid where the battery is kept topped up, PHEVs (and full electric vehicles) need to be capable of repeated deep discharge.

The PHEV Prius conversion requires about 9 kWh in battery capacity and the PHEV version of the Volt has about 16 kWh so that the engine becomes a range-extender simply to charge the battery with the GM E-Flex system. In August 2007, Toyota obtained approval for testing on road of a plug-in version of the Prius, the first small PHEV to be certified thus, though DaimlerChrysler has a small fleet of PHEV vans under test. With PHEVs, a lot of driving, particularly short trips, can be in battery-only mode, hence zero on-road emissions. They can reduce overall petrol/gasoline consumption by something like 30 to 50 percent, but will consume most of the difference as electrical power - predominantly from the grid. Power consumption is variously quoted at around 0.16 kWh per kilometer but requiring 50% more capacity than power used (IEA 2008), to 0.3 kWh/km per ton mass.

A PHEV with 16 kWh battery giving 30 km range cuts fuel consumption greatly, given that many cars do not travel much more than this daily, though the nickel metal hydride battery pack weighs four or five times as much as the Prius's normal one. Several dozen Prius cars in the USA have been modified to be PHEVs, but at least 9 kWh of battery capacity is needed to have a workable PHEV. In September 2007 EdF announced a program to test four PHEV Prius cars, and that EdF and Toyota had developed an innovative charging and invoicing system to enable a "new generation of public charging stations" which the companies said would reduce the cost to the consumer, and recharge in 90 minutes. However, overnight charging would be off-peak and draw solely on nuclear power without emissions. Toyota itself is working on a PHEV Prius with lithium ion batteries.

The electrical efficiency (mains power to wheels) in PHEV is about 75-80%, or 25-30% overall from primary heat.

In 2005 DaimlerChrysler brought out a PHEV Mercedes Sprinter van prototype, with 107 kW (143 bhp) combustion engine and 90 kW (120 bhp) electric motor. Its batteries give it a 30 km electric range. This may lead to a commercial version with the technology.

GM has unveiled a PHEV, the Chevrolet Volt, with a 16 kWh battery pack giving the vehicle 65 km all-electric range. The Volt is intended for mass production and may be on sale from 2010. The Volt is essentially an electric vehicle with on-board 1.4 litre IC engine as "range extender", to charge the 175 kg battery pack if required and drive the electric motor. Hence it is a series (rather than parallel) PHEV system, similar to diesel electric locomotives and mining haul trucks, though these have no battery storage. The luxury Fisker, due to be marketed in 2009, has 80 km range on battery before the IC motor kicks in and appears also to be a series PHEV.

Toyota plans to introduce a PHEV equipped with a lithium ion battery for fleet customers in Japan, the USA and Europe by late 2009 as well as speed up the development of small electric vehicles for mass production, following on from its FT-EV concept car.

The Chinese F6DM is a plug-in hybrid made by BYD and backed in the USA by Berkshire Hathaway. It has a lithium ion phosphate battery giving it a range of 100 km on that alone. It can be recharged in 9 hours. The BYD F6e is a fully electric version.

PHEVs are likely to remain competitive even when there is an option for the on-board energy carrier to be hydrogen rather than simply a battery and the on-board electric power plant is then supplied through a fuel cell, so plug-in hybrid-electrics have a long-term application.

Ford has an Airstream PHEV concept car powered by a hydrogen-electric hybrid drivetrain: the HySeries Drive. The lithium-ion battery pack drives the vehicle and a compact steady-state fuel cell system is a range extender - the fuel cell’s sole function is to recharge the Li-ion battery pack as needed, using 4.5 kg of hydrogen on board. It can also be mains charged.

Full Electric Vehicles (EVs)

These are an extension of the PHEV concept that actually predates it. Plenty of these have been built, but mostly with heavy lead-acid batteries and for uses other than motor cars, though the small Indian G-Wiz car used in the UK has lead acid batteries. General Electric produced the EV1 in the 1990s, first with lead-acid batteries then with NiMH batteries, but the 18 to 26 kWh on board did not give enough range and recharge was slow. Today Tesla Motors, Phoenix and others are preparing to build EVs with over 35 kWh on board, using lithium ion batteries. The Tesla Roadster is reported to have 56 kWh on board and to recharge its 45 kg of batteries from a 13 amp mains supply in 16 hours, or rapidly in 3.5 hours.* Its motor is 185 kW.

Electric vehicles have two important disadvantages to compared to internal combustion vehicles. Firstly, power reaching the electric vehicle has undergone: transmission loss, distribution loss and thermodynamic combustion loss of about 65 percent, meaning that 65 percent more fossil fuel must be burned to compensate for that transmission loss. Note that some states are less efficient than others in distributing electricity; for example, California is about four times more inefficient than the most efficient grids. Some countries have very high transmission loss; for example, India has about nine times the transmission loss compared to the USA. Secondly, electric vehicles do not receive the free energy given to internal combustion vehicles via the alternator system. This latter loss account for about 12 percent poorer fuel efficiency than generally reported in carbon generation.

Another problem with electric vehicles is battery fade, a phenomenon in which full charge declines with each charging cycle, and thus range is progressively diminished. For example an EV with a range of 200 miles would have range diminished by to 140 miles after three years in service. (Xia, 1997 )

EVs and series PHEVs can eliminate the mechanical transmission (as well as the complex parallel PHEV control system) and have a drive motor/generator in each wheel, though this will affect the unsprung weight adversely and hence roadworthiness. But this is a very simple system and requires minimal further development apart from optimizing batteries.

In May 2008 Nissan (with Renault) announced that it would downplay PHEVs and would mass-produce full electric vehicles from 2010 for Japan and US markets. This series uses advanced lithium ion batteries in the floorpan with an effective life of five years and will recharge in 6 hours at 100 volts to give 160 km range**. A higher voltage (200v) rapid charge will enable recharge in 30-60 minutes. The initial Mixim concept has two 50 kW motors, front and rear, but later developments have a motor at each wheel. Nissan entered mass market EVs in 2012.

Mitsubishi has developed the iMiEV with 16 or 20 kWh lithium-ion battery pack giving it a range of 160 km with the latter (at 18 kW power instead of the full 47 kW). It has hub motors and regenerative braking. It recharges from 220 volts in 7 hours (presumably at 13 amps), but can also take 80% charge in 35 mins. It may be marketed from 2010.

The Norwegian Think (formerly Pivo) once owned by Ford has its Think City with 200 km range, and sodium batteries available as alternative to lithium ion. Think quotes 10 hours recharge from 230 volts for full recharge. The mass is 1.4 tons including 260 kg battery pack.

In the UK, the company which makes London's black cabs is to develop an electric-powered version, designed for congested urban areas. Manganese Bronze has signed an agreement with Tanfield, to develop a battery-powered version of its TX4 London cab - the TX4E. Tanfield subsidiary Smith Electric Vehicles is the world’s largest manufacturer of road-going commercial electric vehicles.

The new cab can potentially replace many of the city's 20,000 licensed cabs. It has a top speed of 80 km/hr and a range in excess of 160 km on one battery charge. It is powered by an advanced electric drive train and an iron phosphate lithium-ion battery pack. The technologyis Tanfield/ Smith's all-electric system, recharged off-peak in 6 to 8 hours, and capable of rapid top-up in an hour. Running costs are expected to be well under half those of the present TX4 diesel version.

BMW introduced the Mini-E, which has a 35 kWh lithium ion battery pack taking up the back seat area and weighing 260kg. It can be charged in 8 to 10 hours from a household wall socket (presumably at 16 amps on a 240 volt system, 35 amps on 110 volts) or in two hours with special fittings. A 150 kW motor gives the 1.5 ton car a range of 250 km.

Daimler has had EVs on test in London and plans to produce and market them more extensively. For many uses batteries on their own will be inadequate on several counts - they have poor performance in hilly regions, in winter temperatures and when the driver wants to run heating or air conditioning. While many battery vehicle drivers become well disciplined in their vehicle use so they can plan their journeys around the requirements of battery charging, the plug-in electric hybrid (PHEV) technology remains attractive to give greater versatility. This would mean 16 kWh per hour, so 64 amps charging rate on a 240 volt system. With 40 kWh in batteries this would be almost 70 amp charging rate.

Sources of electricity

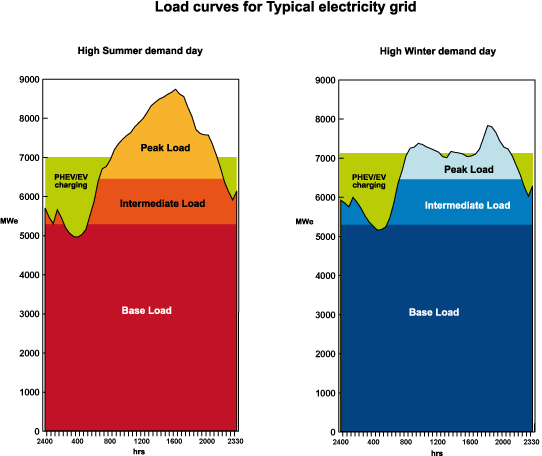

The UK Department of Transport has estimated that if the UK switched to battery electric vehicles, electricity demand would rise about 16%. The US Electric Power Research Institute modeled 60% of US vehicle use being electric and found a 9% increase in electricity demand. As can be seen from the graphs above, this need not increase the system's peak capacity if most charging is off peak, thereby significantly increasing the proportion of total generating capacity supplied by base-load plant. Areva has calculated that if 10% of cars in France were electric it would increase base-load demand by more than 6000 MWe (

The UK Department of Transport has estimated that if the UK switched to battery electric vehicles, electricity demand would rise about 16%. The US Electric Power Research Institute modeled 60% of US vehicle use being electric and found a 9% increase in electricity demand. As can be seen from the graphs above, this need not increase the system's peak capacity if most charging is off peak, thereby significantly increasing the proportion of total generating capacity supplied by base-load plant. Areva has calculated that if 10% of cars in France were electric it would increase base-load demand by more than 6000 MWe (

While all electricity generation technologies including renewables will play a part in meeting increased electricity demand for PHEVs and EVs, the positive implications of the scenario on nuclear power (especially for future nuclear fusion) are:

• The PHEV and EV requirement for electrical power (particularly off-peak power) may increase relatively soon as the concept of PHEVs gains wider acceptance, because the technology is all available.

• When fuel cells using hydrogen are in common use, PHEVs will remain attractive because if drivers can charge batteries from the mains power for even 15 cents/kWh, or from their on-board generator at a dollar per kWh, they will choose the less expensive method some of the time, especially because it provides zero emission driving.

PHEVs and EVs to a large extent will be able to utilize power at off-peak times (and at lower rates), hence drawing on {C}base-load grid capacity and increasing the demand for that. This will mean lower average cost of power generated in the grid system, since the base-load component will become a very large proportion of the peak demand. If vehicle to grid (V2G) feed in peak periods is enabled, that will help reduce costs further, but there are some complexities to be overcome for this to happen.

Some battery technologies allow short-duration high-current opportunity charging that means an overall increase in power generating and distribution demand. The increasing electrical load will occur at a rate that can be accommodated by normal planning for additional power resources and infrastructure. PHEVs and EVs can contribute to oil independence, as well as cleaner air. Ford estimates that the payback period for the price premium on a PHEV is seven years.

PHEV technology is seen as the base for later utilization of fuel cells simply because hydrogen is likely to be at least as expensive as petrol/gasoline and therefore any ability to use mains power will be economically attractive. Supplementing this is energy conservation (from regenerative braking) to a battery. The choice of technology for a PHEV power plant is likely to have much less impact than the plug-in aspect of the design enabling the use of base-load mains power.

Battery technology and charging

This is the key for both PHEV and EV: achieving low cost with high capacity and low mass, coupled with safety and a long life. They need to be capable of repeated deep discharge.

While current automotive fuels provide 12-14 MJ per kilogram mass (net of IC engine efficiency, 45 MJ/kg thermal), the best batteries provide only 2-3 MJ/kg (550-800 Wh/kg net), and that at twice the volume. Commercial batteries are much less than this (see below).

Lead-acid batteries are well known in traction roles as well as for starting cars and running accessories. But they are very heavy and only last a few years.

Nickel metal hydride (NiMH) batteries are well-proven and reasonably durable, though they can be damaged under some discharge conditions.*The batteries are similar to nickel cadmium (NiCd) batteries, but use a hydrogen-absorbing alloy as the cathode instead of cadmium.

Research continues on lithium ion batteries, which deliver more power from less mass but still have some safety, reliability, and durability problems. Early ones used cobalt oxide cathodes, newer ones use manganese oxides or iron phosphates, which tend to be less efficient but more reliable.

Ultracapacitors are another research frontier to provide electricity storage for cars, to supplement batteries in providing for acceleration, and also being able to accept high inputs from regenerative braking.

Lithium ion batteries hold about 100-170 watt-hours per kilogram of battery mass, the much safer and more durable lithium iron phosphate batteries being at the lower end of this range. These compare with 29 Wh/kg from metal hydride (NiMH) batteries in today's Prius (though other published figures for the batteries give 70 Wh/kg) and 30-40 Wh/kg from lead-acid batteries. But the Li-ion cost is now around US$ 1000/kWh.

Lithium ion batteries are specified for the GM Volt and the Fisker, and intended for Ford's forthcoming PHEVs and the electric London cab. However, most of those are likely to use more advanced ones with lithium iron phosphate (LiFePO4 or Li2FePO4F) cathode, the latter giving a lower power density but greater service life. Both kinds are much safer than early ones with lithium cobalt dioxide cathodes. The Volt is charged in eight hours from 120 volt outlet or half that from 240 volts, so presumably at 16 amps.

Nissan has joined with NEC and a subsidiary, NEC TOKIN, to set up Automotive Energy Supply Corporation (AESC) to develop and market advanced laminated Li-ion batteries for use in PHEVs and EVs. AESC commenced operation in May 2008.

Nissan, EdF, and others envisage an infrastructure integrating three types of charging systems: from household supply overnight (6-8 hours, off-peak), similar slower charge in parking lots during the day, and fast charging points which will give up to an 80% charge in 30 minutes. In addition to these there should be 5-minute battery pack changeovers for long trips, raising the possibility of batteries being leased rather than owned, or electricity suppliers selling a service configured for different users, not just batteries and power.

Focusing on the home base, using a 13 amp plug such as standard in UK, and 240 volt system, a 16 kWh battery pack such as in the GM Volt could be recharged in 5.5 hours. Many battery packs will be much larger than this, so 40 amp charge points may often be necessary for overnight charging, particularly with 110 volt systems.

- If a cell in a multiple assembly fully discharges the others may drive it to reverse the polarity and permanently damage it.

Fuel cell vehicles

Experimental fuel cell vehicles (FCV) are now appearing, starting with buses. For sources of hydrogen for these see companion paper Transport and the Hydrogen Economy.

Honda has unveiled its FCX Clarity hydrogen-powered fuel cell vehicle with lithium ion battery pack and announced plans for marketing it. The motor is 100 kW AC, with Proton Exchange Membrane fuel cell stack and 170-litre compressed hydrogen tank giving a range of 620 km. Vehicle mass is 1.6 tons. The first US deliveries began in 2008 in southern California with a three-year lease term at a price of $600 per month, including maintenance and collision insurance. Over three years to 2011 Honda deployed about 200 of these vehicles, some of them in Japan.

Toyota has announced that it has developed a fuel cell hybrid vehicle - Toyota FCHV-adv - equipped with a high-performance fuel cell stack and nickel metal hydride batteries. The design of the membrane-electrode-assembly (MEA) has been optimized to allow for low-temperature start-up and operation down to minus 30°C. Fuel cell output is 90 kW, matching the motor which delivers 260 Nm. Efficiency was improved by 25% from the earlier FCHV through improving fuel cell unit performance, enhancing the regenerative brake system and reducing energy consumed by the auxiliary system. In the 1.9 ton 5-seat vehicle a 70 MPa pressure vessel is used to store hydrogen which allows for an operating range of more than 800 km in the Japanese driving-cycle.

Beyond the electric vehicle initiatives described above, the Renault-Nissan Alliance is developing fuel cell-powered electric vehicles. In 2008 two prototypes were in an advanced engineering phase:

Nissan’s X-Trail FCV has been undergoing ‘real world’ testing for more than two years, with examples leased to government authorities in Japan.

Renault's prototype Scenic ZEV H2 FCV is a joint Alliance development featuring Nissan’s in-house developed fuel cell stack, high pressure hydrogen storage tank and compact lithium-ion batteries. Renault put the different FCV elements under the floor, to keep cabin space for five adults, and integrated Renault and Nissan electric and electronic systems.

Both FCVs have been created to demonstrate the viability of the fuel cell concept and to underline the Alliance’s commitment to a zero emission future. During 2008 Nissan is demonstrating the X-Trail FCV in six European countries and Renault is showcasing the Scenic ZEV H2. In August 2008 Nissan announced a new generation stack with power output increased from 90 kW to 130 kW, for larger vehicles. Fuel cell stack size is reduced by 25% to 68 liters from 90 liters, which allows for improved packaging flexibility.

The Mercedes-Benz B-Class with fuel-cell drive has passed its winter testing in northern Sweden and Mercedes will be launching the first series FCV in mid 2010. Small-series production of the B-Class F-Cell will commence in early 2010. A refined, more compact, yet more efficient system is used in this than the A-Class FCV. The electric motor develops 100 kW and a maximum torque of 320 Nm, surpassing those of a standard 2-litre petrol engine. At the same time, it uses the equivalent of just 2.9 litres/100 km of fuel (diesel equivalent).

An issue with using hydrogen in fuel cells is overall energy efficiency. If a nuclear reactor generates electricity which is used for electrolysis of water and the hydrogen is compressed and used in fuel cell powered vehicle, the efficiency is much lower than in the electricity is used directly in EVs and PHEVs.* However, if the hydrogen can be made by thermochemical means the efficiency doubles, and they are comparable with EV/PHEV.

- Say 35% x 75% x 30-40% = 8-11%, cf 35% x 70% = 25%.

See Also

References

- Qiang Dai, Jarod Kelly, Linda Gaines and Michael Wang (2019) Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Systems Assessment Group, Energy Systems Division, Argonne National Laboratory, DuPage County, Argonne, IL 60439, USA. Batteries 2019, 5(2), 48; https://doi.org/10.3390/batteries5020048

- Romm J.J. & Frank A.F. 2006, Hybrid Vehicles Gain Traction, Scientific American April 2006

- Anguan Wu, Baoshan Ni · 2016 . 'Line Loss Analysis and Calculation of Electric Power Systems, Wiley

- X. Li, O. Malik and Z. Zhao, "Computation of Transmission line Transients Including Corona Effects," IEEE Transactions on Power Delivery 4, 1816 (1989).

- Jignesh.Parmar (July 1, 2013)Total Losses in Power Distribution & Transmission Lines 'https://electricalnotes.wordpress.com/2013/07/01/total-losses-in-power-distribution-transmission-lines-part-1/

- May 03, 2017. The Inconvenient Truth about Electric Vehicles. https://oilprice.com/Energy/Energy-General/The-Inconvenient-Truth-About-Electric-Vehicles.html

- Economist Technology Quarterly, 10/6/06.

- Brown, Russell 2006, Critical Paths to a Post-Petroleum Age (ANL paper).

- Phil Jones & David Barber

- R. Hunwick, Plug in Vehicles presentation 16/10/07.

- OECD/IEA 2008, Energy Technology Perspectives.

- Xia, Y. (1997). "Capacity Fading on Cycling of 4 V Li/LiMn2O4 Cells". Journal of the Electrochemical Society. 144 (8): 2593. doi:10.1149/1.1837870.

Distributed by:

World Nuclear Association, 22a St James's Square, London SW1Y 4JH, UK

E-mail: wna@world-nuclear.org,